Maybe it’s because I just got back from a mountain bike ride with a grueling, grinding, steep climb. But I got inordinately excited about today’s patent from Fox. it seems Fox is toying with a composite chainring that should in theory reduce lateral flex. That means you lose less pedaling power to component movement. (Where were you an hour ago, Fox??)

And the three parts of the carbon chainring get mated to each other without pins or bolts. More on that below.

Fox owns RaceFace, so that’s likely where you’d see this product should it come to market. Here’s how it works.

A flat disc…in three dimensions

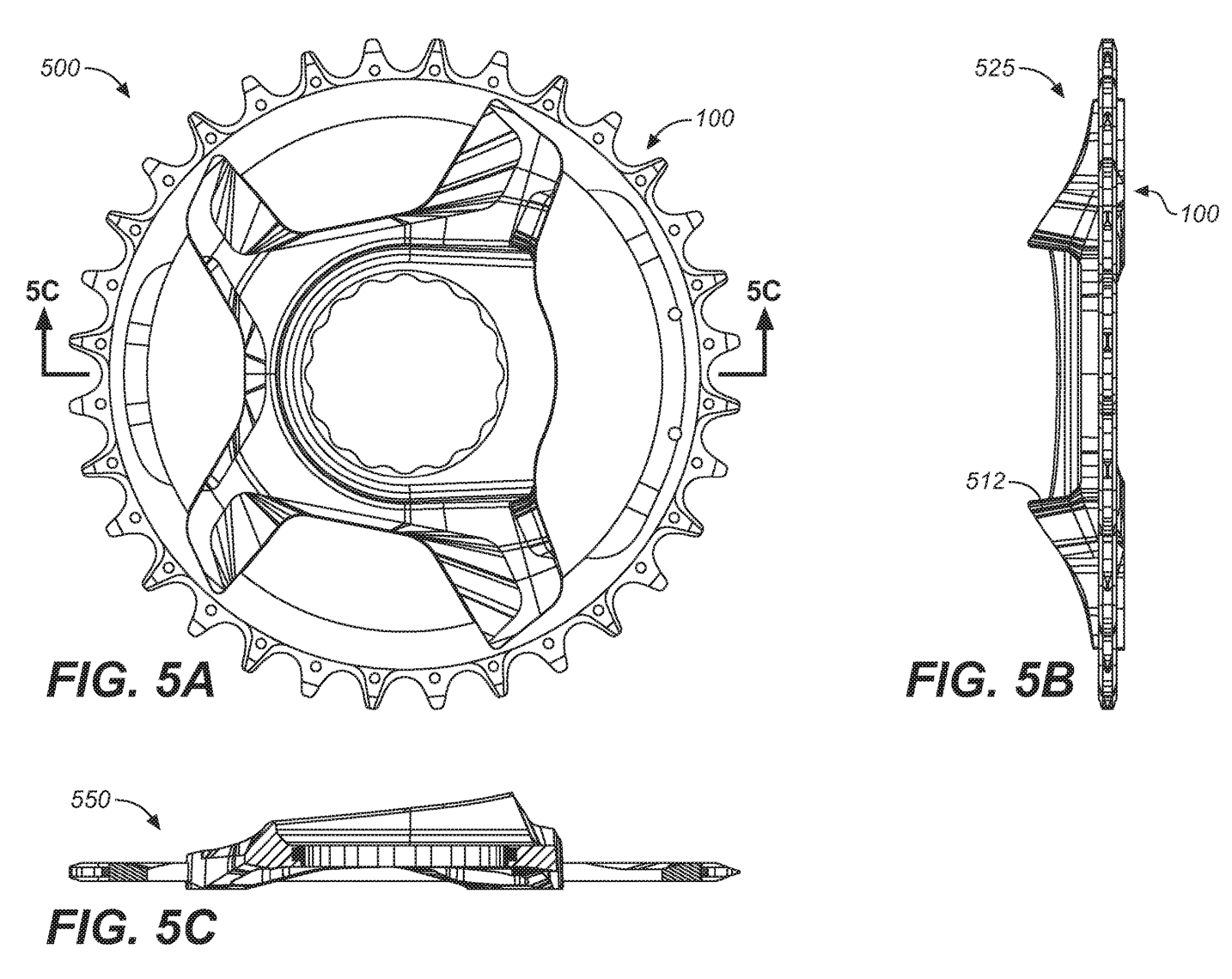

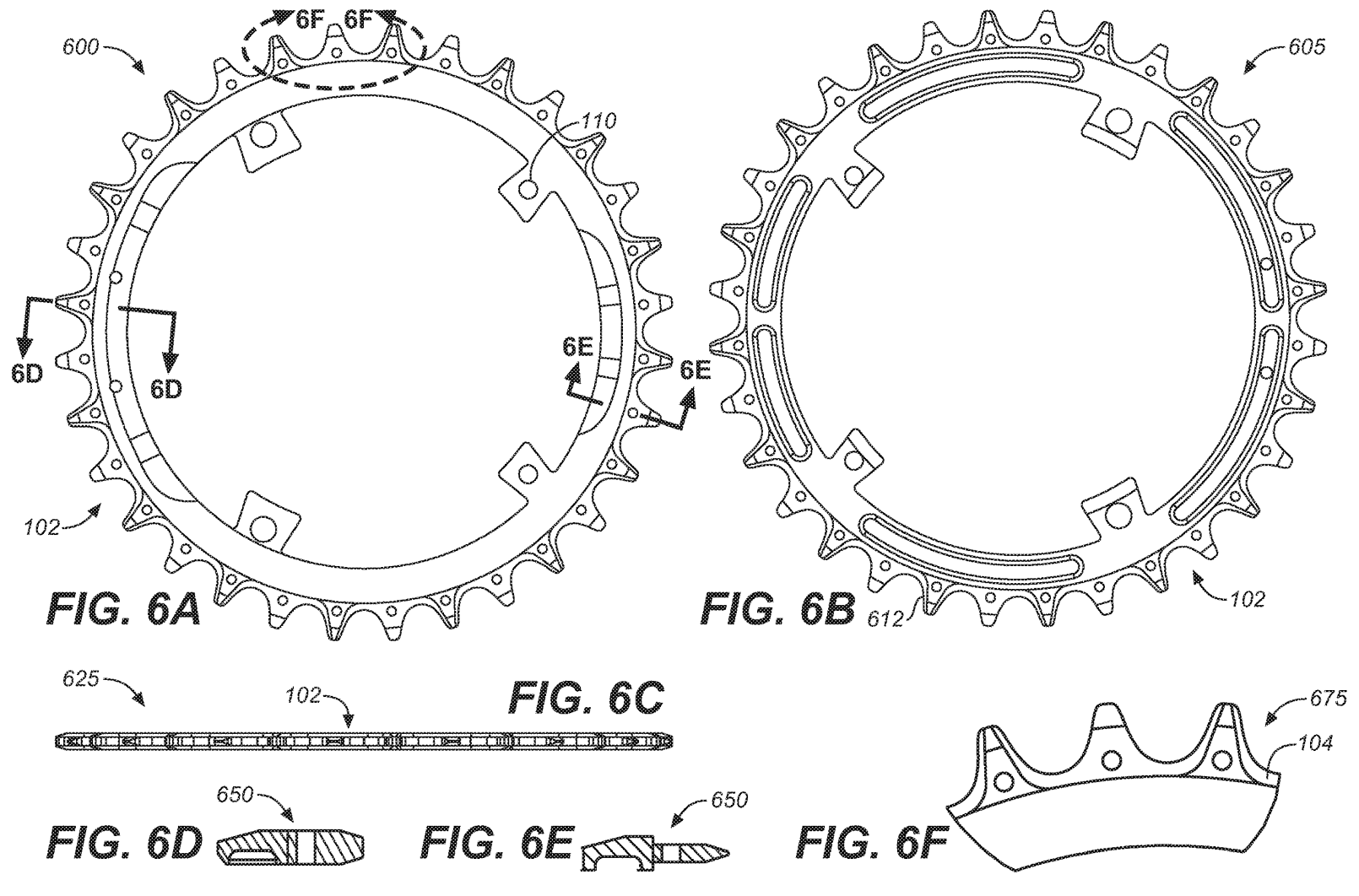

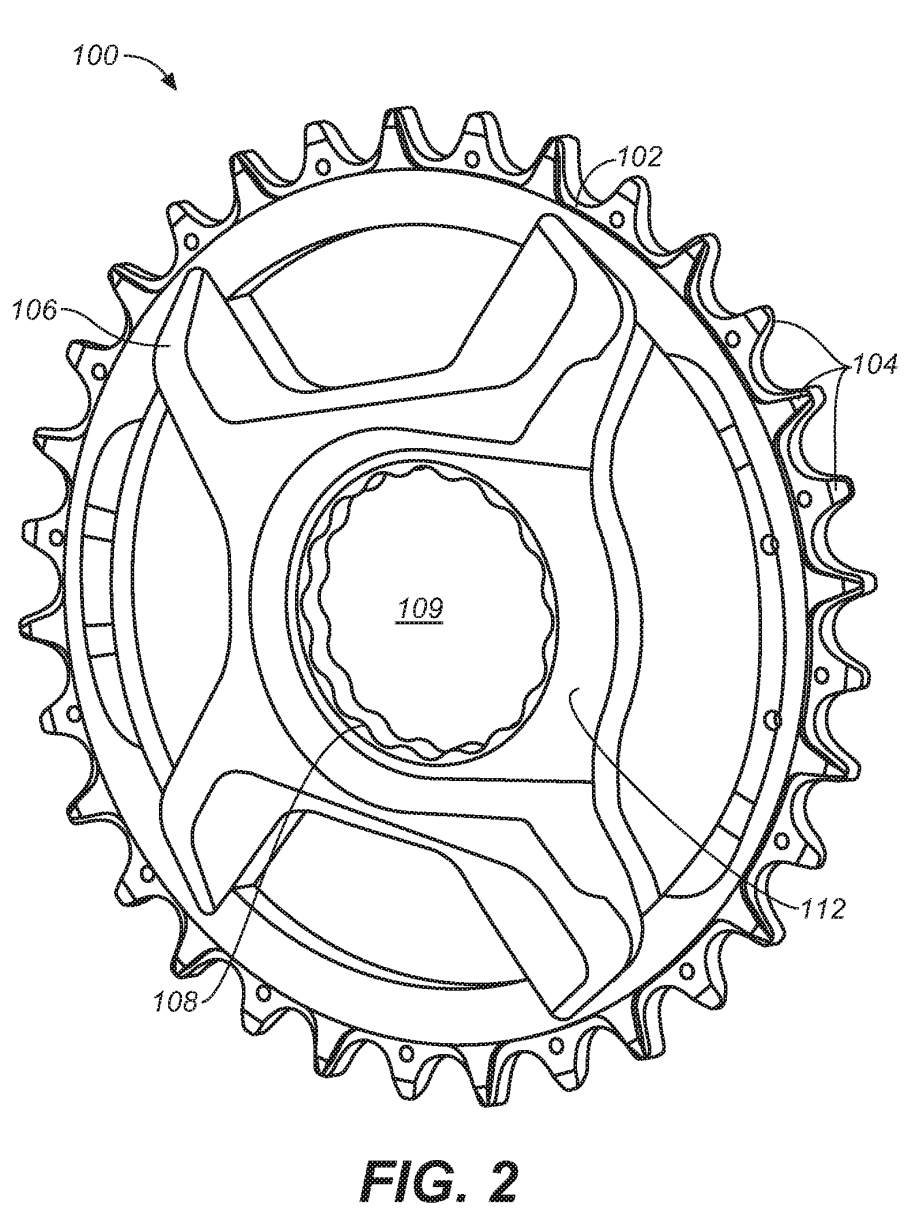

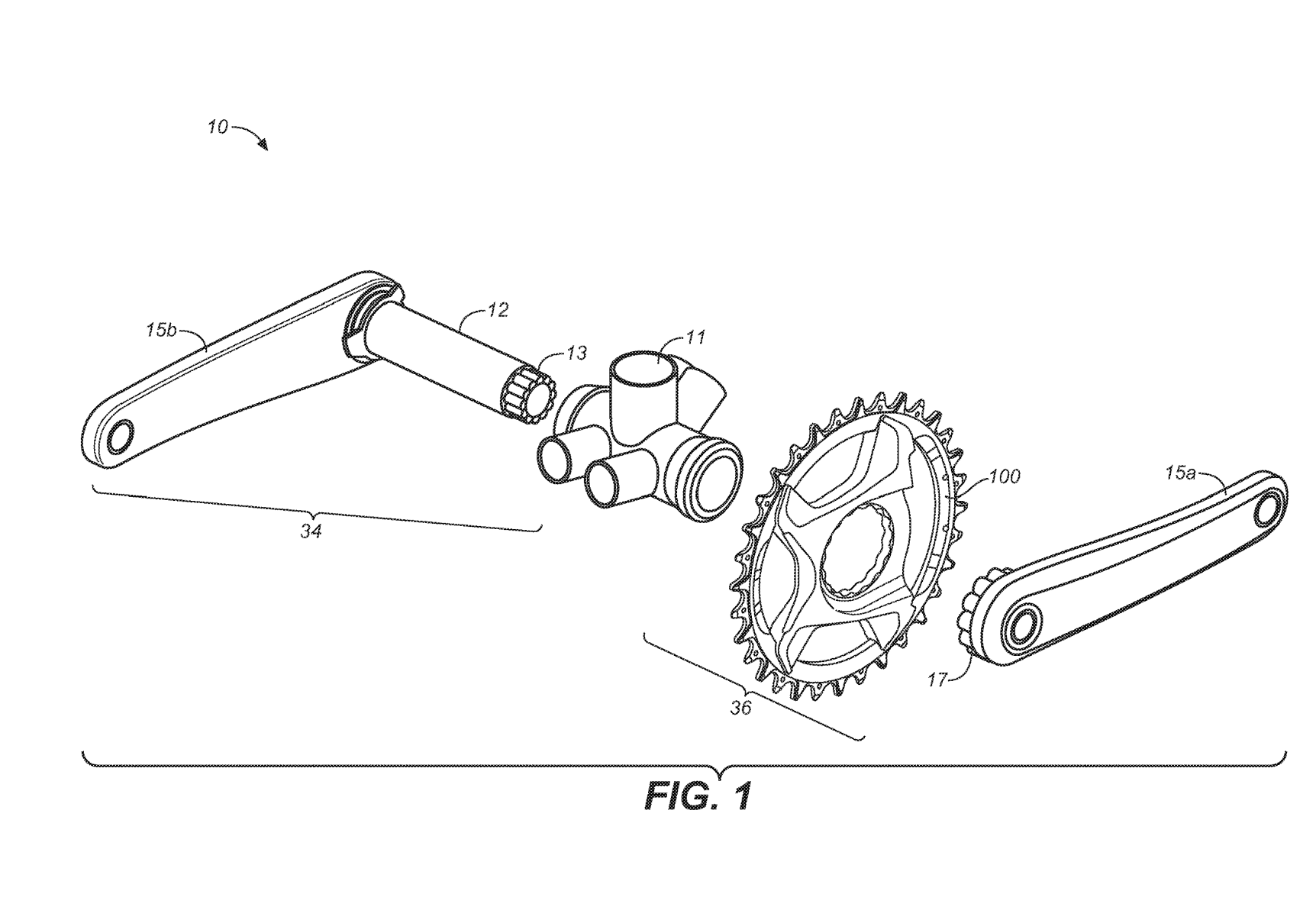

Fox’s chainring is a bit unglamorous at first glance: it’s a chainring, after all. But the patent outlines a composite structure: the outer ring is of course made of metal, since that’s where the chain will interface. But that outer ring mates to an inner structure, likely made from carbon. The inner structure in turn will mate with the crank.

This allows Fox to easily tailor the shape and dimensions of the inner portion of the chainring, without adding significant weight to the works. in other words, Fox’s carbon chainring can increase lateral stiffness while keeping weight to a minimum.

This matters most for 1x drivetrains. Expect to see this chainring (if it appears at all; a patent doesn’t necessarily mean a product will follow) on mountain bikes. A carbon chainring like the one outlined here makes most sense on 1x drivetrains with wide gear ranges, which fits the bill perfectly for mountain bikers.

That’s because as the chain reaches gears on either extremes of the range (i.e. the highest gears and the lowest gears) the chain line runs at an angle in relation to the chainring more dramatically than it does at the center of the cassette. That subsequently means more lateral torque gets transferred to the chainring itself.

What does the carbon chainring solve?

When the chain line changes that dramatically, it places more torque on the chainring. This poses two problems: first, more of your pedaling power gets lost to flex. And second, components tend to wear more quickly. The carbon chainring concept reduces the overall flex at the chainring, thereby reducing energy loss and increasing component durability.

So that’s neat-o. But how exactly is it different from any other chainring? It’s all about depth. It’s possible to mold the inner carbon structure in any number of ways, so you can hypothetically tailor the inner structure to maximize lateral stiffness. Since carbon in general is quite light, this likely won’t add much weight into the chainring (and it may even reduce the overall weight, or at least it could).

It’s that last point that matters, too. Plenty of chainrings already exist that take advantage of lateral depth to stiffen things up. Sometimes that means making the crank itself wider or stiffer where it mates with the chainring. Sometimes that means making the aluminum carrier on the chainring wider, and therefore stiffer.

In this patent, Fox is creating a single chainring from three components, one of which features injection-molded carbon fiber reinforced with nylon. The patent outlines other materials for this center portion: nylon reinforced with carbon, chopped carbon, and even some plastic polymer versions.

While we have indeed seen carbon fiber chainrings before, this appears to be a novel use for it. Fox’s carbon chainring idea seems to capitalize on the versatility of materials beyond aluminum and steel to create a durable yet laterally stiff chainring.

Affixing the carbon chainring to the crank

I had to read this section a few times to make sure I was reading it right. But it appears the patent that outlines a system in which the components — the outer ring and the inner composite portion — are connected without bolts, pins, or other fasteners.

That’s possible due to thermal expansion. Once the composite center and the outer ring get loosely mated to each other, they can be heated, and then cooled. During the cooling process, the outer ring should contract more than the carbon inner portion. The two components will therefore mate to each other tightly.

The same concept works with the carbon chainring center, where an aluminum lockring gets mated to the center of the carbon carrier. This is the surface that will mate directly with the crank itself, so carbon isn’t the best material choice here. Using the same thermal expansion principals as above, the center ring mates to the carbon carrier permanently.

The carbon chainring is a cool concept that will certainly appeal to mountain bikers, and even gravel riders, in search of the stiffest drivetrain components possible. In that sense, the carbon chainring design seems ideal for racers. But since mountain bikers are likely to encounter dramatic terrain changes that require high-torque pedaling, the chainring makes sense for just about all riders.

Of course, a carbon chainring certainly doesn’t sound cheap. And there’s always a durability worry with carbon, especially when it encounters lateral impacts that can tear the fibers themselves (think about your shoes repeatedly rubbing against the crank).

Still, it’s an intriguing concept. Do you think we’ll see a carbon chainring like this hit the market soon? Would you buy one for your everyday rig, or is it just for the racer crowd? Let us know in the comments below.

Patent research assistance provided by Wheelbased.com. Check them out for deeper dives on some of these patents and more.