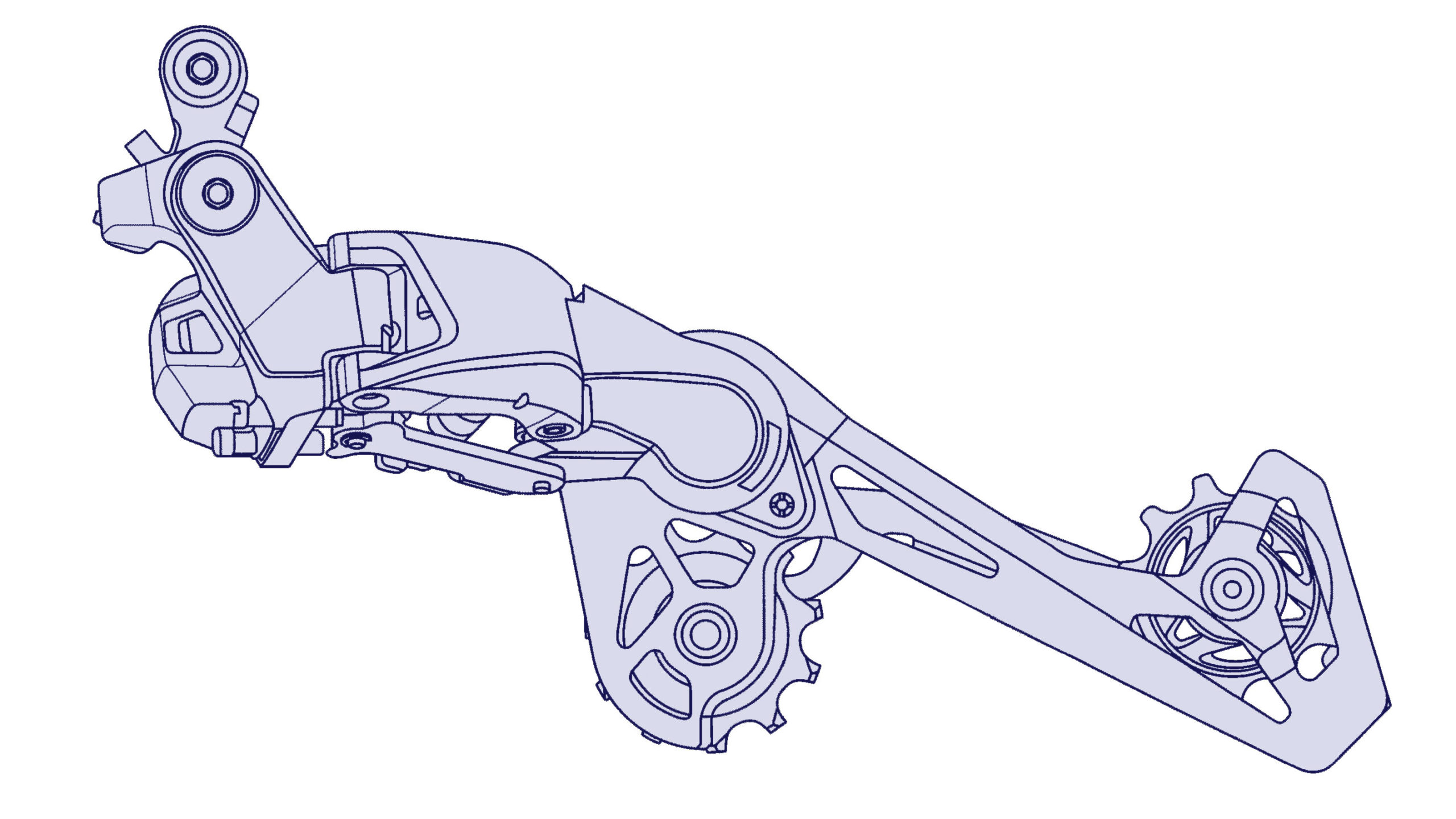

Published just today, Shimano’s latest Di2 drivetrain patent details an all-new, somewhat simpler electronic shifting mechanism that manages to float its shift motor in an isolated manner to better protect it from impacts. Once it’s mounted on the bike, you’d be hard-pressed to spot the functional differences tucked inside. But by employing a second return spring and a couple of lever arms that tuck inside its parallelogram, this prototype Di2 derailleur can handle direct outer strikes and impacts from objects coming off the wheel without damaging the sensitive motor & gearbox inside…

Floating-shift Shimano Di2 derailleur concept patent

Let me just start out by saying that the 42 pages of vaguely descriptive, conceptual legalese in this patent filing are dense. And its 31 diagrammatic illustrations are certainly helpful, but by no means clear in their own right. If you could read through it and come away understanding it all on a first pass, you’d be much better than I.

But I popped a current Ultegra Di2 drivetrain beside my monitor, and waded deep into the weeds to figure out what’s different and why it matters.

So What’s New?

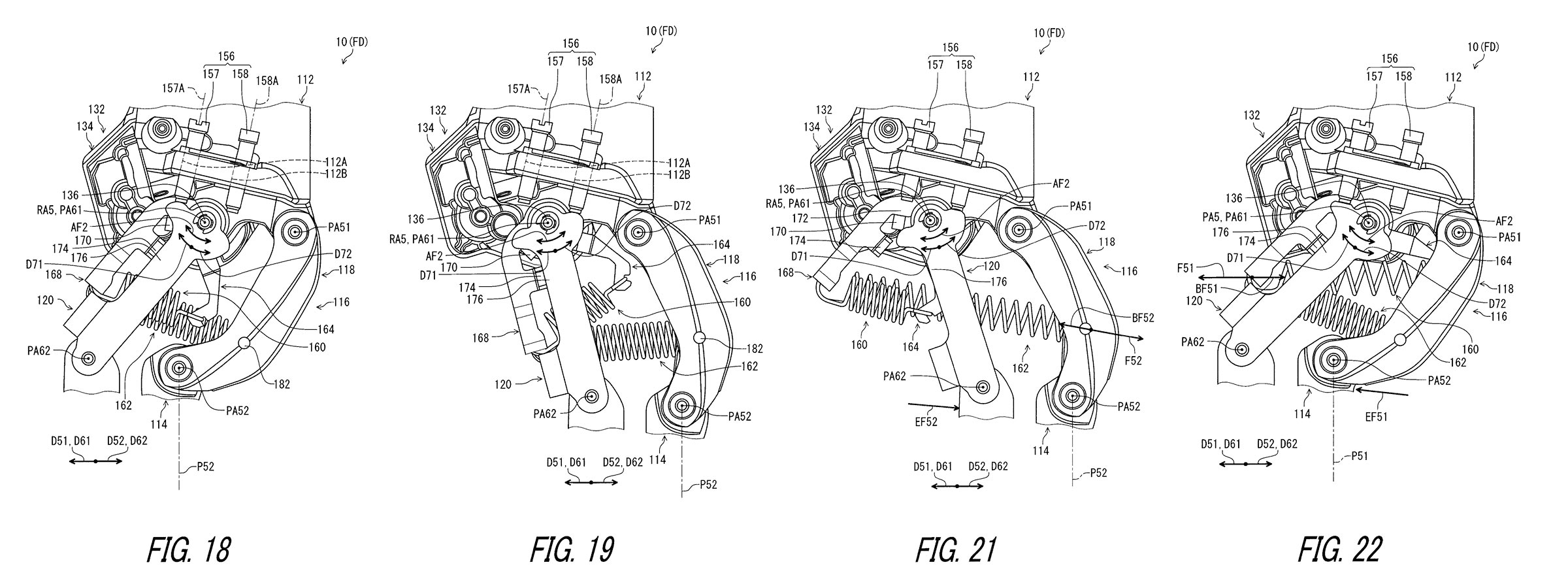

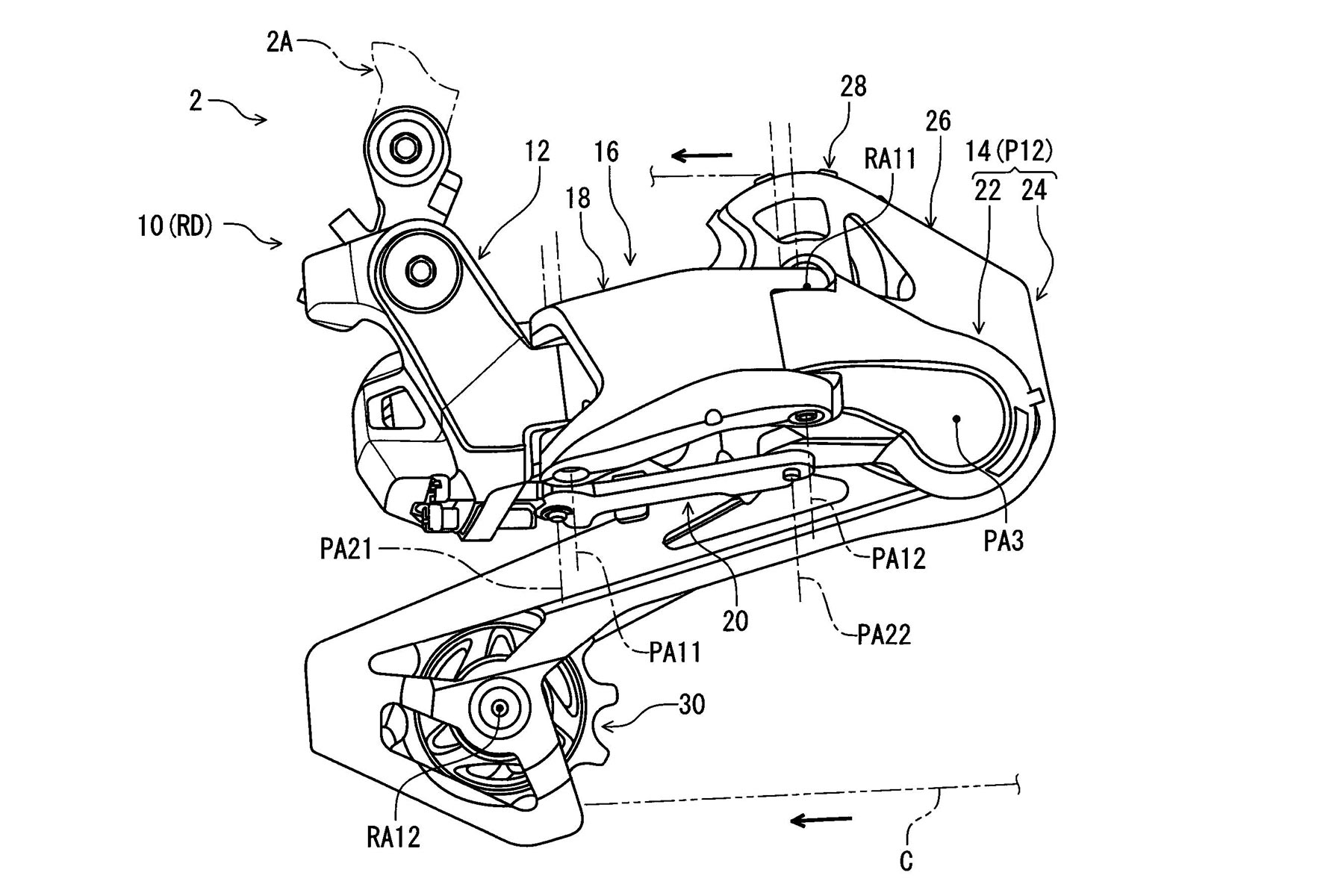

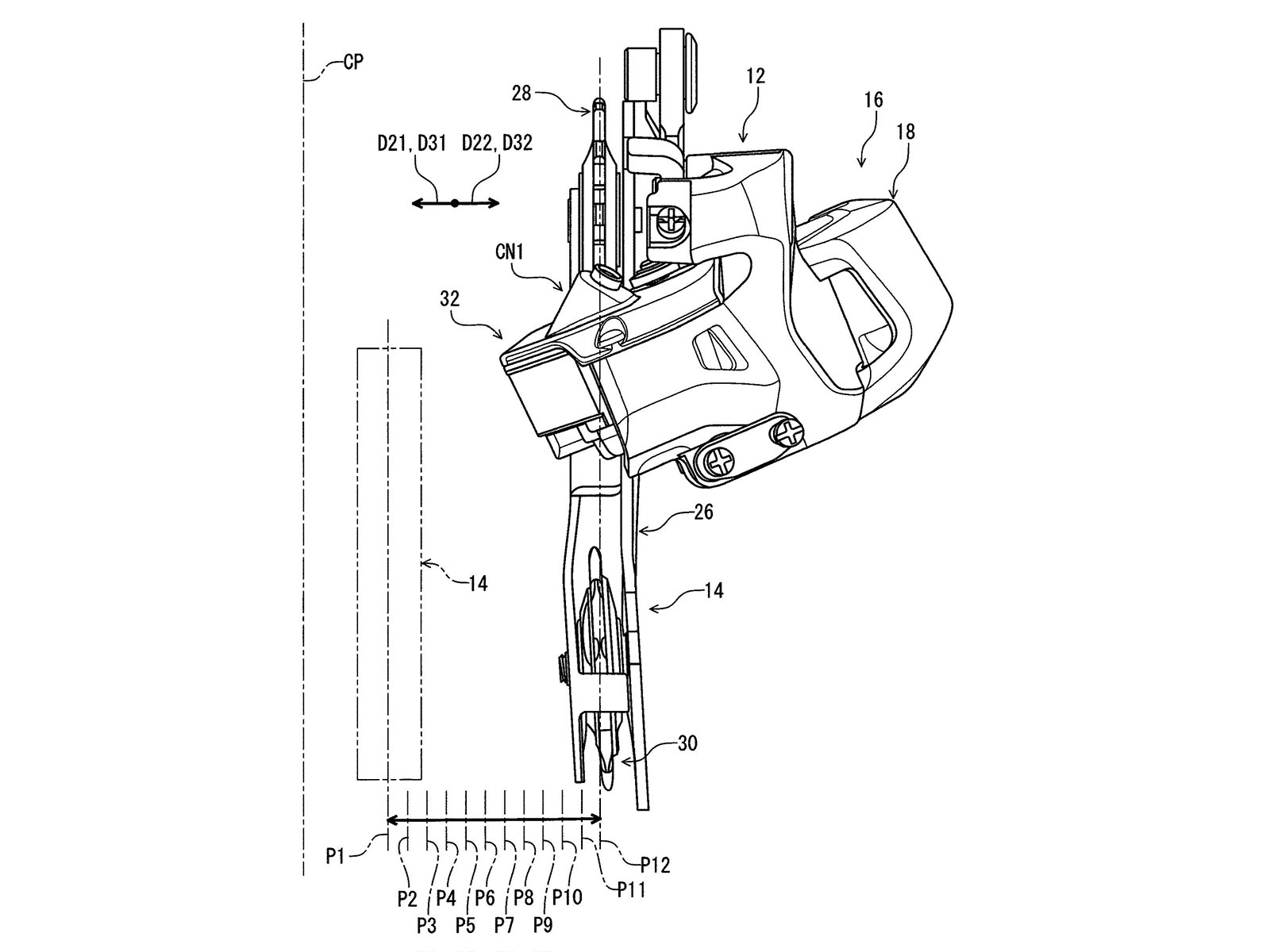

From the patent’s basic description, the key to this new Shimano Di2 derailleur concept is its ability to shift electronically just like you’ve come to expect, but to use two springs within its linkage system that allow the derailleur to move out of the way whenever it is hit from either side. Doing so protects the most expensive and precise bits of the Di2 system – its motorized actuator and internal gearbox – while allowing it to return to center and shift accurately after the impact.

The current Di2 design achieves somewhat similar impact protection and automatic return from an outer impact by driving shift via an inboard link and exposed spring that can slip past a small stop. But if you get something caught between the cassette/wheel and your derailleur it requires a manual reset.

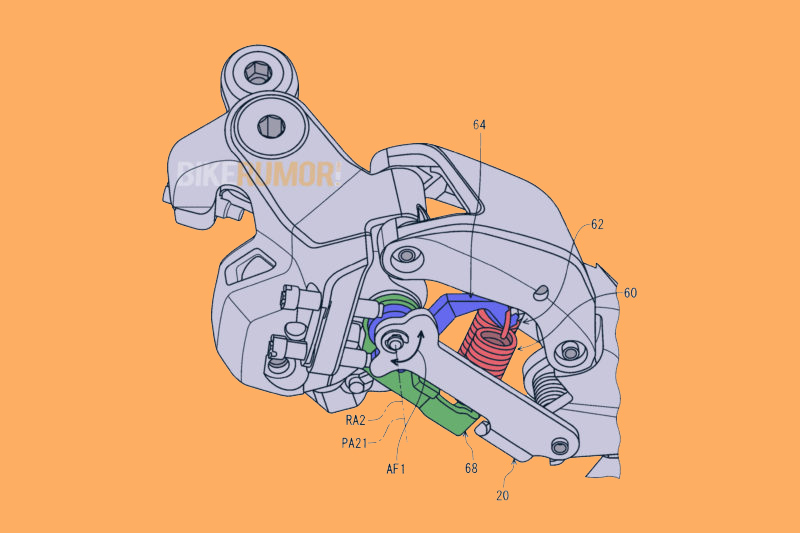

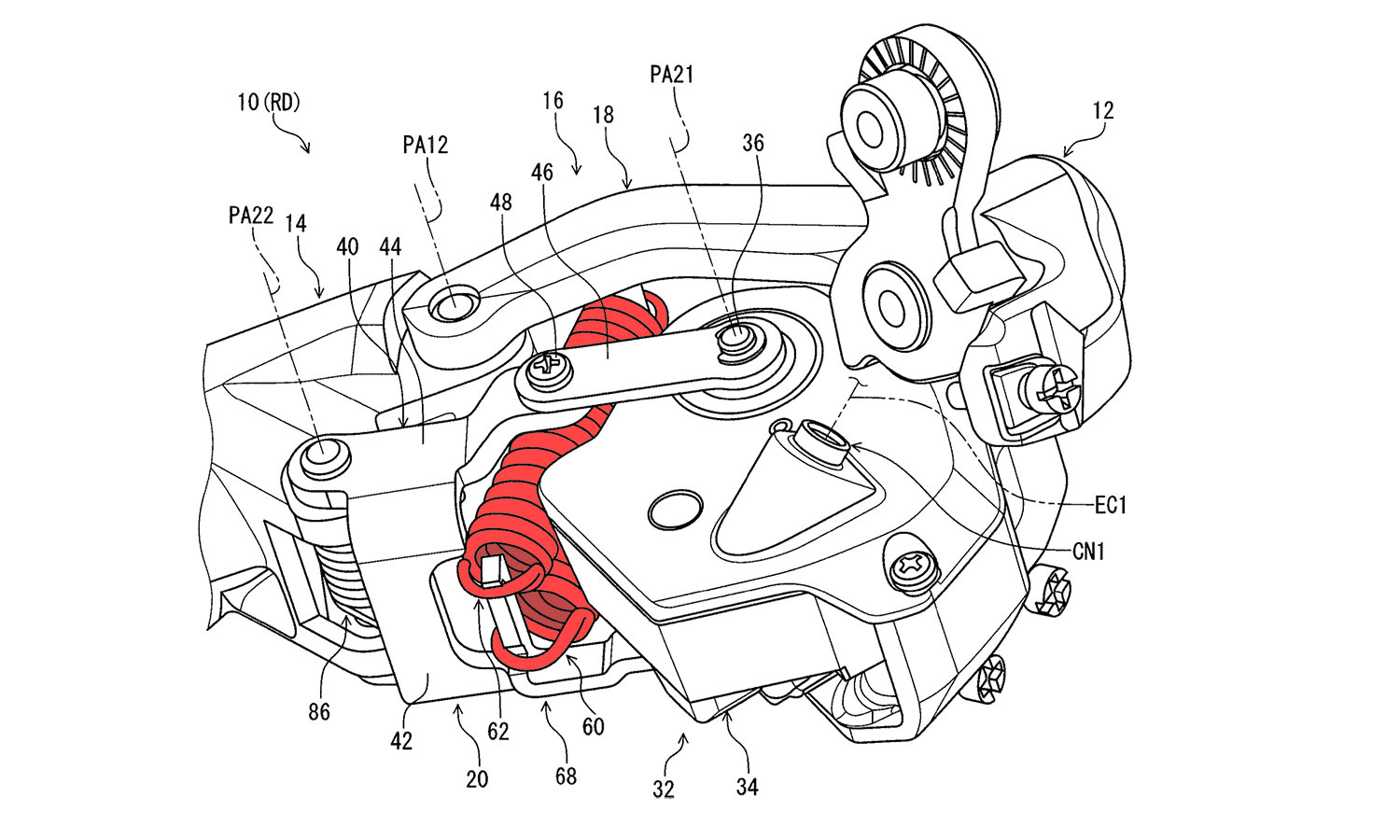

The new dynamic is more automatic & compact, enabling Shimano to tuck all of the mechanics inside the shifting parallelogram. Upshift and a new lever pulls the derailleur linkage outboard to align with a smaller cog via the 1st spring. Downshift and that lever pushes the second “saver” lever to pull the opposite side of the derailleur linkage inboard via a 2nd spring. Since the spring forces are much stronger than the force required to actuate the shift, everything moves quickly & precisely.

But since the parallelogram linkage is essentially floating in between the two springs, any harder force from either side will simply move the derailleur without damaging the gearbox or motor.

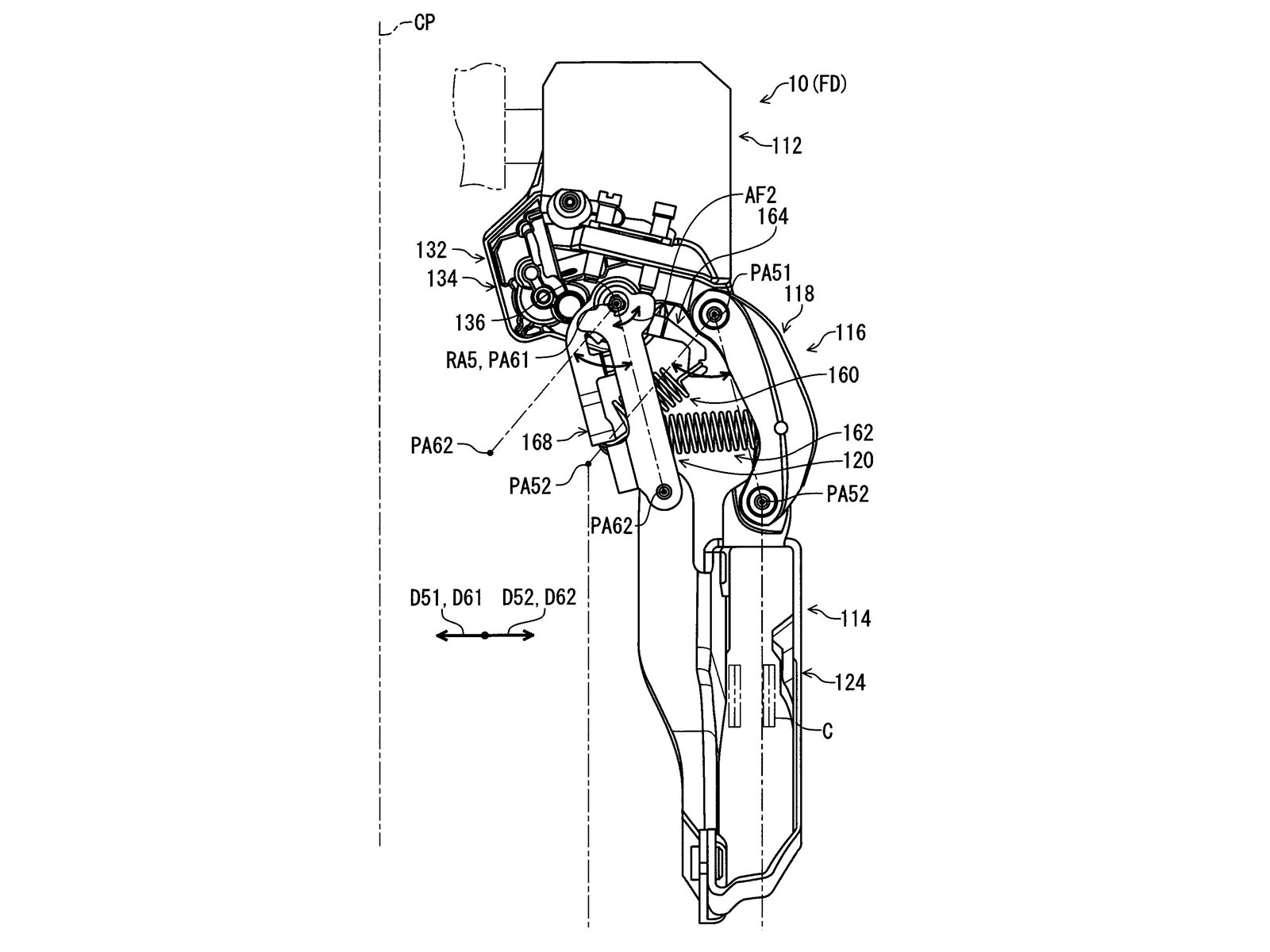

Interestingly, the exact same solution works for the front derailleur too.

Why does it matter?

We all know that you don’t want to have to replace an expensive electronic derailleur, so it’s always been nice that they pretty much all disengage when the suffer a big impact. This seems to just make that disengage mechanism more fluid, while adding automatic recentering in both directions. We scratched our heads to wonder why you really need impact protection from both sides. but it is certainly conceivable that a rock flying up off the rear wheel could strike the inside of your derailleur, or something could get jammed between the cassette and derailleur body when riding gravel or off-road.

In any case, the inherent floating design allows for movement and impact protection in both directions.

Now, the question remains…

When we might see this in production?

It’s only been a year and a half since both Dura-Ace & Ultegra got their latest Di2 update (and just half a year since 105 Di2) so we don’t expect a new road Di2 group anytime soon. It has been almost 4 years since gravel’s GRX Di2 debut, though. We have been anxiously awaiting a new XTR Di2 group ever since XT got an ebike-only Di2 last summer. It’s been almost 9 years since the current XTR Di2 M9050 groupset was revealed!

If this new impact-resistant Shimano Di2 derailleur patent design is coming soon, it’ll likely be off-road!