The folks at SRAM know how much of a pain it can be to inflate a tubeless tire. Seating a tubeless tire properly can mean the difference between awesome ride quality and a quick pit stop on the site of the road. So SRAM’s patent shows a redesign to the inflation valve to make it easier to get tubeless tires to seat.

How inflation valves work now

Tubeless wheels come with inflation valves that you pop through the valve hole and seat into place. And the valve is generally held there by a threaded nut.

The inflation valve — assuming it’s a Presta valve, which is most common on bicycles these days — has a small threaded barrel at the tip. Unscrewing this barrel opens the inflation valve’s air chamber.

The part of the valve that sits within the rim itself has an opening. Once you attach your pump to the barrel end and start pumping, air flows through the valve and into the rim/tire interface.

The force of the air from the pump shoots directly through the valve. That means the air gets blasted at one spot on the tire. This is essentially a force on the radius of the tire.

Since air needs to apply pressure to the entire tire circumference in order to seat it on the rim, current tubeless inflation valves are inefficient at the seating process. If you’ve ever tried to seat a tubeless tire with a hand pump, you probably already knew this.

What SRAM’s valves change

SRAM’s patent outlines an inflation valve that’s all about that sweet circumference.

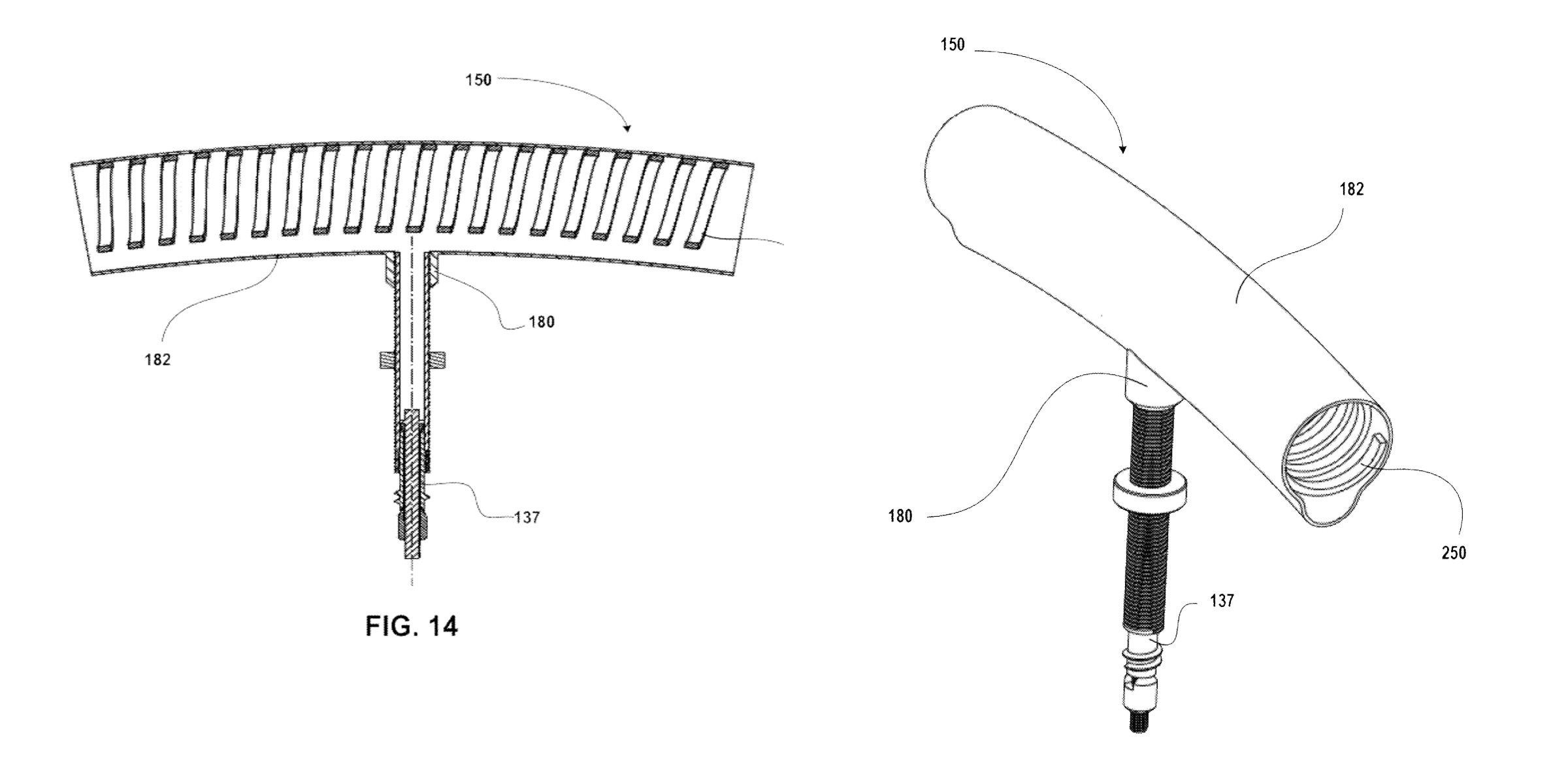

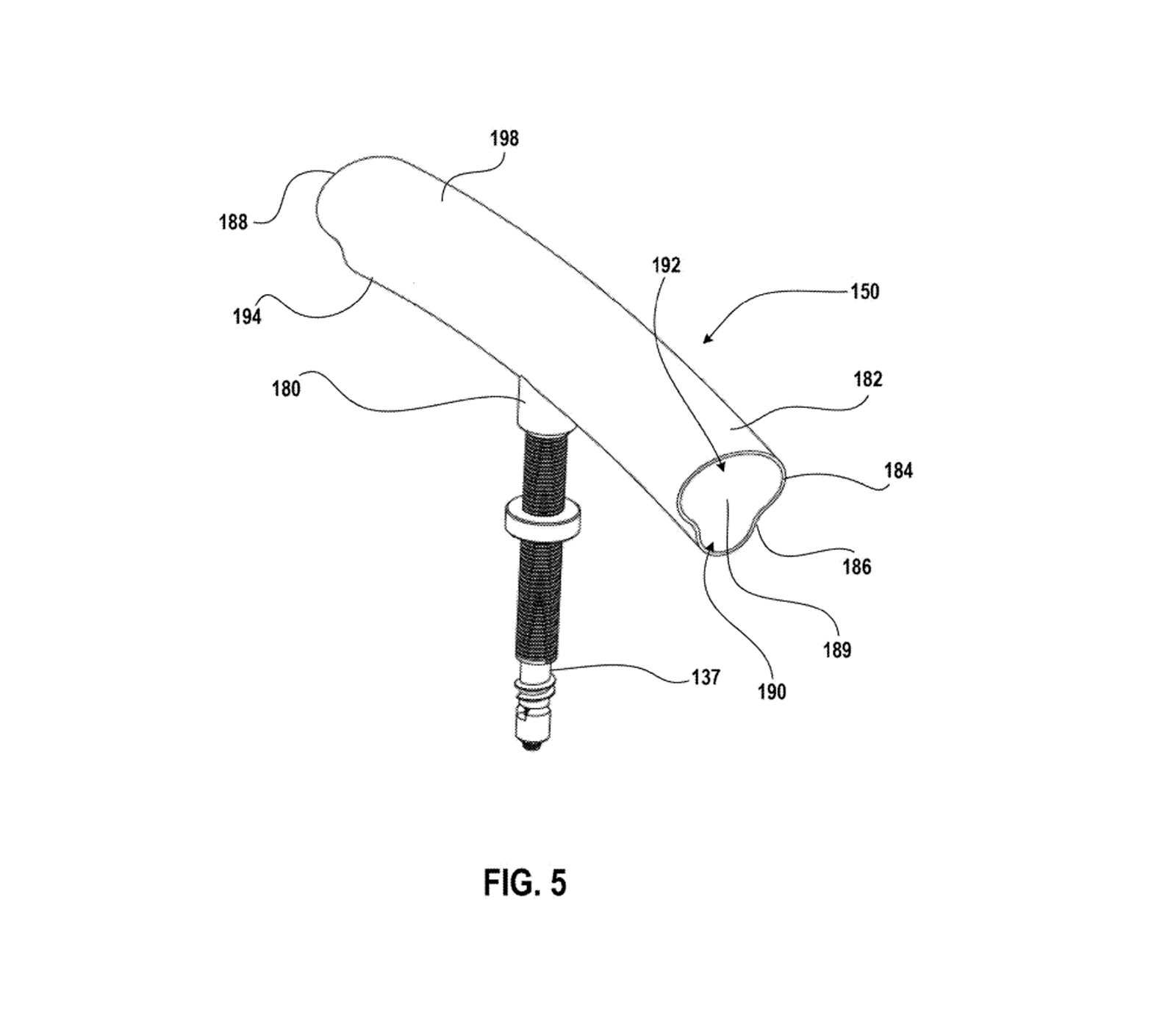

The outside of the valve, in this patent, remains largely the same as what we’re used to. The real magic lies inside. The part of the inflation valve that sits inside the tire and rim features an additional aspect.

A body that sits perpendicular to the valve itself (and is attached to the valve itself) helps redirect some of the inflation air around the circumference of the wheel. That should make it easier for you to inflate and seat your tubeless tires, even with a hand pump.

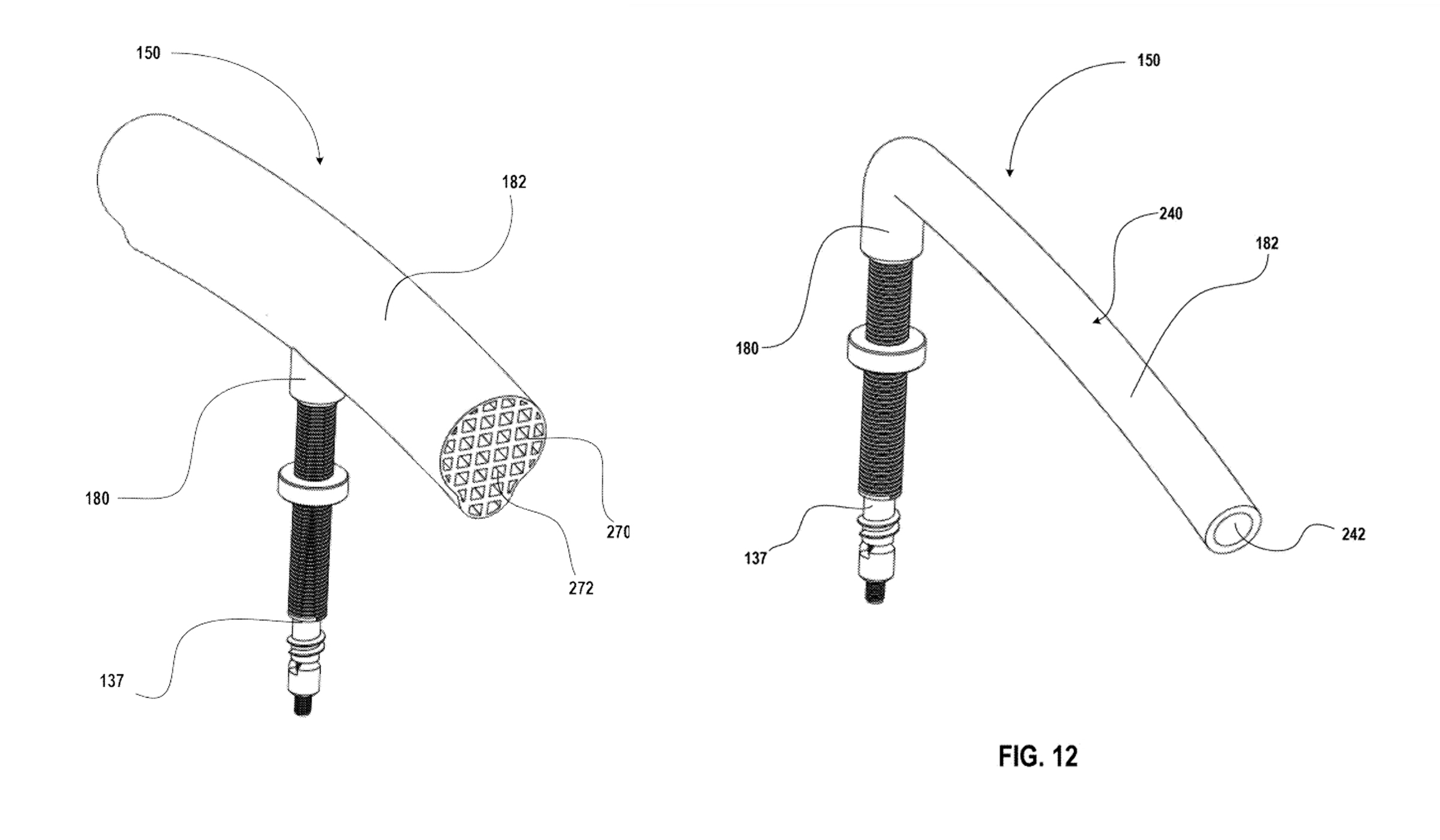

The patent outlines several versions of what may ultimately become the finished product. The simplest version features a tube-like structure attached to the valve itself. This would likely be made of rubber, like an inner tube.

Other versions outlined in the patent expound on this simple concept. The tube itself may feature reinforcing ribs or structures inside, for example. These could serve a dual role. First, such structures would help keep the tube itself open at all times. Second, the structures in the valve channel can help redirect air more efficiently.

Is it cool?

If it works, yes! And SRAM’s not the only company chasing this unicorn inflation dream.

Tubeless tires are only becoming more prominent in all disciplines in cycling. Mountain bikers have long suffered through the finicky nature of inflation valves and tire/rim combos. Now, with road riders and gravel riders cottoning onto the advantages of tubeless, it has only become more important to have easy inflation methods.

So SRAM’s invention would certainly make life easier for cyclists of all stripes. It would eliminate, or at least reduce, the need for an air compressor when seating tubeless tires. It could indeed make it very easy to inflate and seat tubeless tires with a hand pump, too.

Another nifty advantage to SRAM’s potential inflation valve system is its adaptability. A lot of mountain bikers have caught onto the benefits of tire liners like Cushcore. Similarly, gravel riders have begun using such inserts to help prevent flats and improve cornering stability.

The downside? Installation is a huge pain. And once you get the inserts inside your tire, you still need to inflate the tire and get it to seat. SRAM’s inflation system can help there by blasting air along the circumference of the tire and liner, rather than directly at it.

This should, in theory, make it much easier to seat tubeless tires even with inserts inside. My blood pressure just dropped thinking about it.

Patent research assistance provided by Wheelbased.com. Check them out for deeper dives on some of these patents and more.