According to Seven brand and sales manager, Craig Gaulzetti, everyone at Seven has bike side projects. “However you can love bikes more or be more passionate about them, do it.” This explains why it is home to ten or so builders who, outside of the company walls, build under their own brands. Craig himself has a brand, Gaulzetti Cicli. Another builder from Seven, Bryan Hollingsworth, was also exhibiting at the show under Royal H.

Boasting a special status as the world’s largest custom bicycle manufacturer, Seven claims 35,000 custom steel, titanium, and carbon frames over its history. The brand continues to push the depth of their capabilities; their SL and SLX level, titanium tubing is externally butted to tailor the geometry and ride-feel to each customer’s particular need.

And at Philly Bike Expo, they shared their latest “Editions of One” project, where Seven designers and builders create one-off bicycles to challenge their status quo. This year, the bike is an homage to bicycles at the beginning of the 20th century, complete with custom cockpit and a proprietary drivetrain.

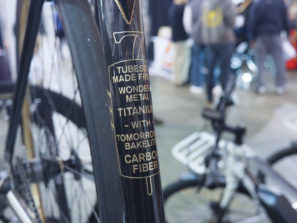

This “Editions of One” build plays with both “Wonder Metal,” titanium, and carbon fiber- the “Bakelite of Tomorrow.” The titanium lugs and filament wound carbon tubes are designed with such precision that there is actually an interference fit between the two.

The real story is in the components, however. For this project, Seven fabricators created a modern titanium stayer stem, completed with a Seven logo faceplate. Custom branded flourishes could be found throughout the build.

Seven also machined this custom cable-actuated rear derailleur in-house. The whole system is tensioned via a wheel under the chainring. Front and rear axles are secured by titanium tri-wing-nuts (which, rumor says, was the most difficult aspect of the build from a fabrication standpoint).

This model won’t be for sale anytime soon. It is, however, able to be ridden, and will be at the Pioneer Ride later this year.

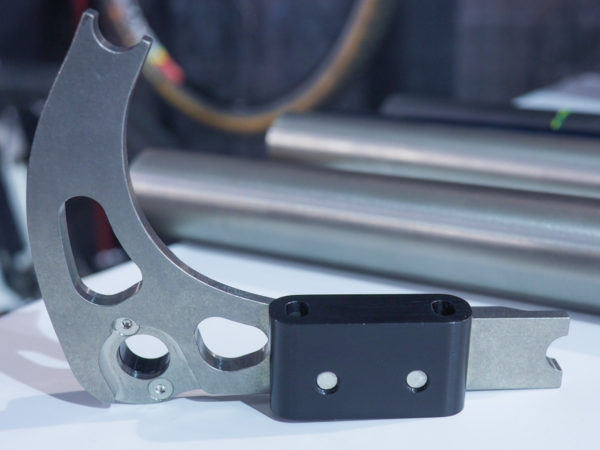

Also new and exciting for the show is Seven’s flat mount compatible dropout system. In it, an aluminum flat mount interface is bolted to the inside of the dropout, while axle interfaces and derailleur tab are bolted through the dropout body. The resulting system is light, modular, and clean.