It was not a surprise to anyone to hear that Chris Bishop would take home the People’s Choice Award for the 2017 Philadelphia Bike Expo. His iridescent pink laser bike had a way of stopping everyone in their tracks as they rounded the back corner of the hall. The bike’s customer collaborated with Bishop and his painter for the elaborate visual finish, working in 3D platforms to ensure that the prismatic effects would wrap properly around the different surfaces of the frameset and cockpit. And while the finish had a way of easily winning attention, it is Bishop’s detailing and immaculate execution of the frame itself that continued to draw show-goers in.

But Bishop’s show winner was far from the only stunner in his booth; he brought a slew of stand out creations.

The finish encompassed the frame, fork, Silca frame pump, and Pro EVO Stealth handlebar.

The paint theme continues into the custom machined stainless seatstay bridge and the stays of the stainless rear triangle.

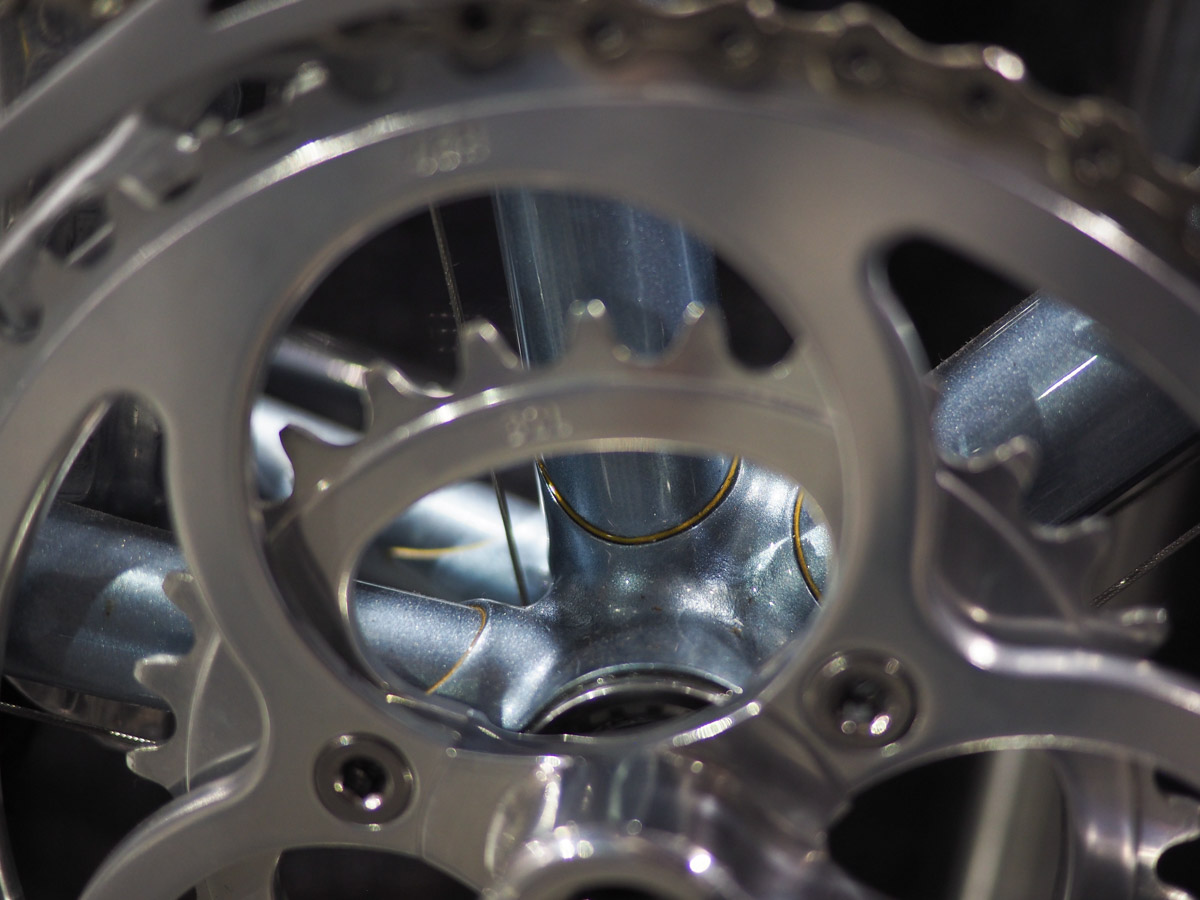

A lovely technical feature of this bike is the way Bishop integrates the dropouts into the chainstays. Rather than have a joint at the end of the tab provided by Paragon on this dropout, for example, Bishop wraps his stays around the outside of the dropouts and carves the ends to match up with the window for a more integrated transition.

And while the prism bike was exciting and all, this pink bike was sitting right next to it.

This head joint is deceptively simple. To make these oval Vari-Wall tubes (one of which is a Chris Bishop custom design) work with the tapered headtube, Bishop constructed special, oval bi-laminate transitions.

Internal routing interfaces on the non-drive side.

Another smooth transition to a bi-laminate interface on the seat tube. Again, more dramatically shaped shorelines and thinned points.

A lightened Bishop seat stay bridge.

A clever and minimal wiring port on the driveside. Bishop flipped the cap to wing the wire over the QR- another nice detail.

The dropouts are modified and thinned Paragon QR flatmount dropouts. As you can see, Bishop again pulls the chainstay around the exterior of the dropout for a more integrated visual and structural effect.

Last but not least is this beautifully executed randonneur.

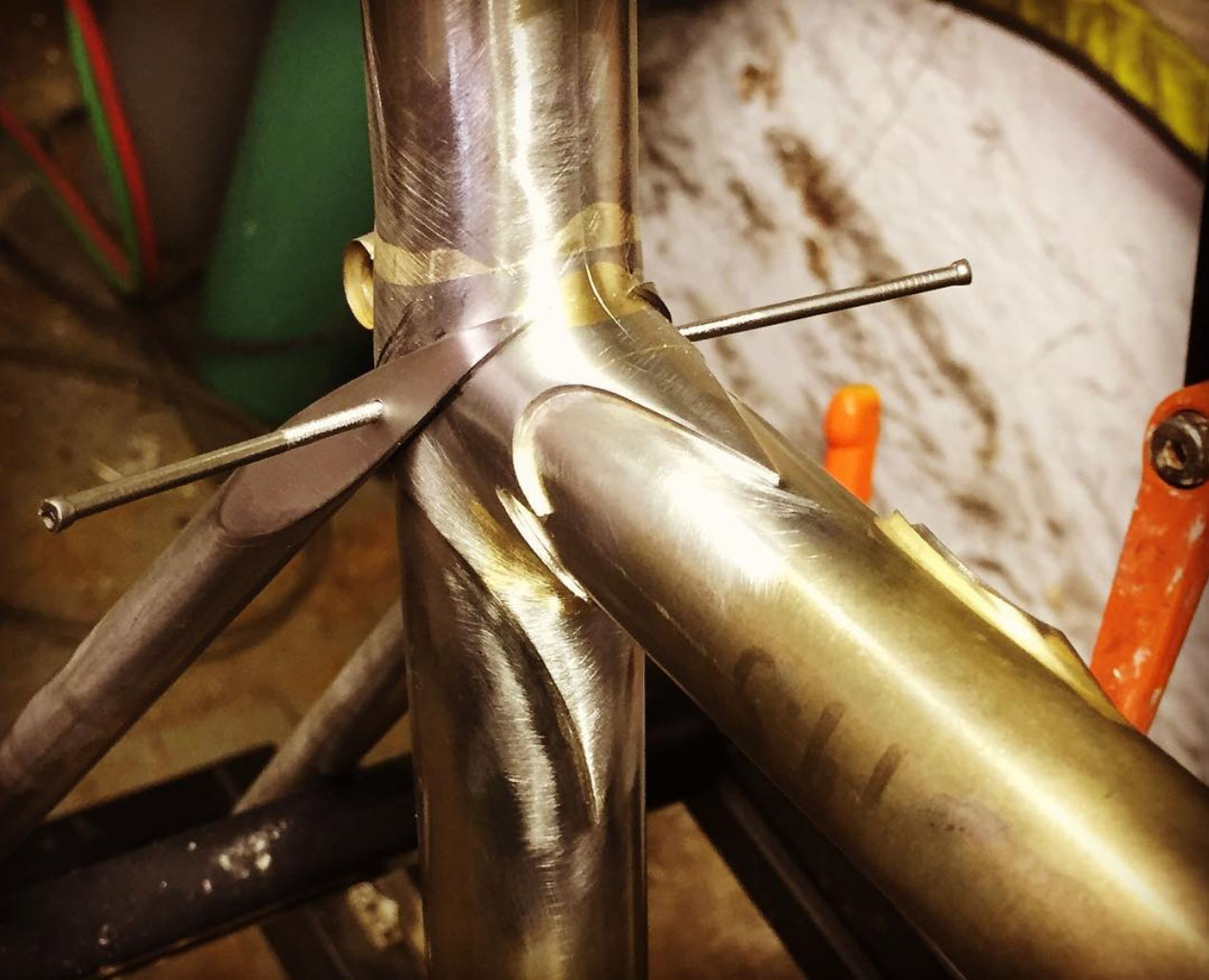

For this frame, Bishop modified a rare and not commonly recognized set of Nervex lugs. He added length to the lateral points so he could carve in his long, Bishopian shorelines and added smooth brass fillets into the transitions. And, again, every point is thinned.

All of the lugs are finely lined in a subtle gold. In person, this striping was so perfect that it was difficult to see in the show lighting.

For the fork crown, Bishop wanted a biplane construction without the stripped-down appearance of a traditional biplane lug, so he hand machined these subtle slots in an existing casting.

For the cluster, Bishop constructed these wrap around caps. In this process photo, you can see the brass line border of the extended top tube point as well as the top of the seat cluster. Also visible are the centerlines scribed into the material to allow him to keep the wrapped capped points perfectly on center (a challenge of this style of end-cap).

For the cluster, Bishop constructed these wrap around caps. In this process photo, you can see the brass line border of the extended top tube point as well as the top of the seat cluster. Also visible are the centerlines scribed into the material to allow him to keep the wrapped capped points perfectly on center (a challenge of this style of end-cap).

The rear of the seat cluster had some nice detailing as well. Bishop machined the clamp assembly for symmetry across the bullet bolt and pinch nut.

The filled lugs extended to the fillets of the bottom bracket.