It’s no secret that Pivot has been testing a new DH bike configuration. Their carbon/aluminum test mules have been spotted on the World Cup circuit for the past two seasons as the Pivot design team has obsessed over the details as Pivot Factory Racing literally pushed them to their limits on the track. But after Bernard Kerr was 3 seconds faster on the new bike on his very first run, even after sustaining an injury the previous day, Pivot knew they were on the right track.

Pivot’s new prototyping protocol

Those prototypes are all completely built from scratch in Pivot’s Arizona headquarters – something we got to witness in person. Building them on-site gives Pivot 100% control over the design, but it also allows for much faster changes to the design if needed. That speed of production and revision is largely thanks to the carbon tube and aluminum lug design.

The goal of the prototype construction method is to match the carbon production bikes in terms of stiffness and performance. Their very first prototype turned out to be too stiff in certain areas, but some quick revisions by engineering wizard Kevin Tisue got them within 3% of their ideal performance goals on the second try. With a goal of allowing riders to hop between production bikes and prototype bikes without noticing a difference in how they feel, the prototypes generally end up about half a pound heavier than the finished carbon versions. Moving forward, Pivot plans to use this prototyping method on all of their bikes, not just the DH bikes.

DW6 or dw-link?

When it comes to the suspension design, Chris Cocalis, the founder and CEO of Pivot Cycles, states that initially they weren’t completely convinced about the 6-bar design. With the team struggling to tell the difference between the 6-bar DW6 and the original dw-link version, the path forward came down to testing. While out in New Zealand, the times were averaging slightly faster on the DW6 bike across the board. And when World Cup victories come down to less than a second, that slightly faster becomes very important.

Officially, Pivot is calling this a Mid-High Pivot Six-Bar dw-link suspension design. According to Cocalis, Pivot started working on the design with Dave Weagle about four years ago. With a more rearward axle path, the suspension offers better square-edge bump performance, but with that comes a need for mitigating chain growth and pedal kickback. Instead of using a more traditional upper idler pully and a very long chain, the Phoenix uses a twin chain design – one that drives the dual-idler from the chainring, and another that drives the cassette from the dual-idler.

Unlike the prototypes, the production bikes will be full carbon using Pivots Proprietary Ride Tuning design which includes size-specific carbon stiffness tuning across all sizes.

Two chain design

Why two chains? Pivot claims this setup is noticeably more efficient, quieter, and has less friction and resistance, while also offering better chain retention. The dual-idler runs on an eccentric mount which allows you to easily tension the smaller chain, and either piece of the drive sprocket can be replaced. It all works out to a 35t equivalent chainring – even though the crankset has a tiny 27t chainring for better trail clearance.

Initially, the upper drive unit was one piece that was very expensive and difficult to produce. To remedy that, the new dual-idler uses a drive sprocket that bolts to the smaller cog using a SRAM 3-bolt direct mount, all made by Praxxis. There’s also a rubber cover on the crank shoulder to prevent any chain slap.

MX Wheels

While the previous Phoenix was a 29/29″ DH bike, the new version moves to MX wheels (and only MX wheels) with a 29″ up front and 27.5″ in the rear. Between the new suspension design and the smaller rear wheel, Pivot was able to increase rear travel by 20mm going from 190mm to a full 210mm. Once again, in their testing, the MX wheel setup with more travel proved to be faster than dual 29″ with less.

Suspension Progressivity Flip Chip

One of the more interesting parts of the design is how do you create a bike that can be ridden by one of the best riders in the world like Bernard Kerr, but a bike that is still able to be effectively raced by mere mortals? The answer it seems is to create a bike within a bike. Pivot has given the Phoenix a Suspension Progressivity Flip Chip that changes nothing but the progressivity rate of the suspension. While Bernard will use the more progressive setting which is based on his personal preferences, the rest of us will probably use the standard setting. Bernard gets his bike, and we get ours, with the flip of a chip.

The Phoenix was originally designed and optimized around a Fox DHX2 Coil or Float X2 air shock, and complete builds will either include the Fox Float X2 air with a Factory 40 GripX2 fork for Pro builds, or a RockShox Vivid rear and Boxxer fork on the Ride builds. You can run almost any 225 x 75mm shock with a Trunnion upper and dM8x30 lower mount in coil or air with the proper tune though.

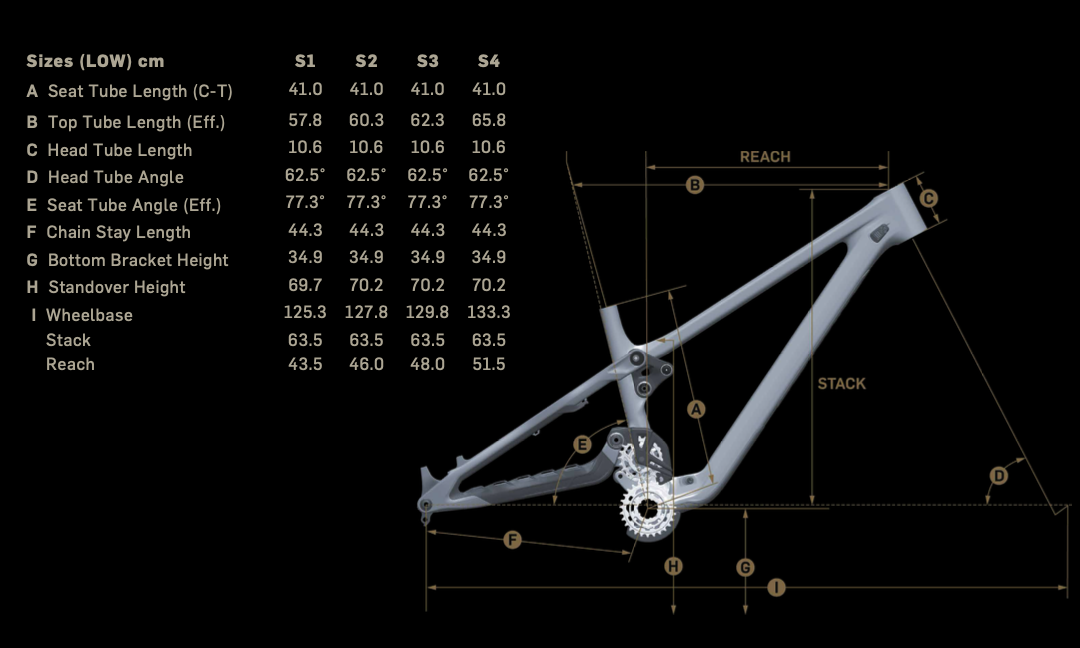

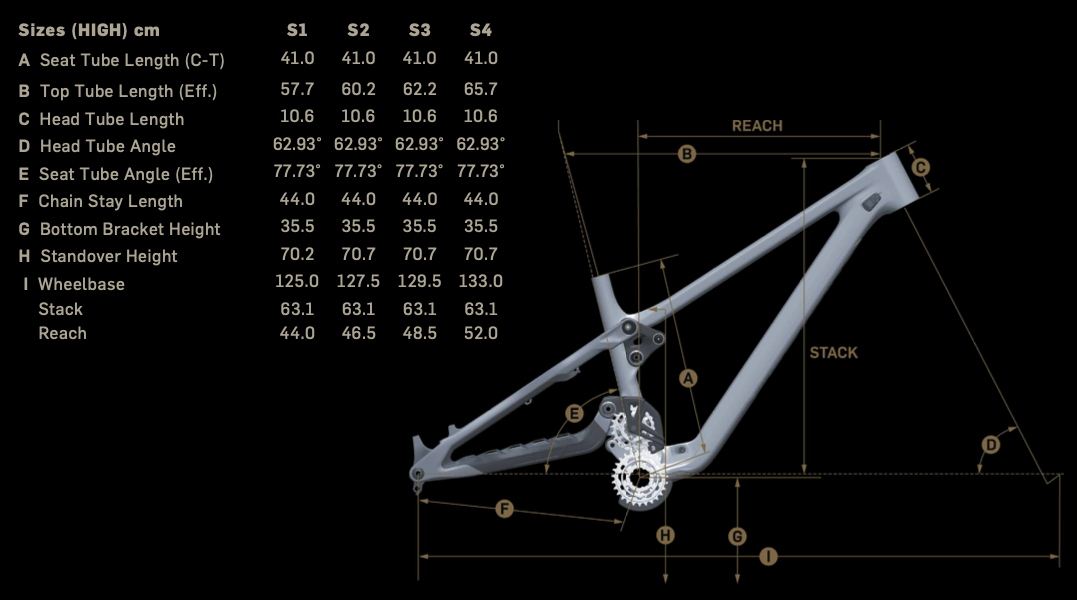

Geometry

For the suspension fork, the frame can run any 29″ specific dual crown DH fork with 190-203mm travel. Pivot is specing the Phoenix with a 52mm offset. They’re also using an oversized straight head tube compatible with 56mm ID headsets (ZS56/ZS56) which allows riders to use angle adjust or reach adjust headsets to fine-tune their fit.

The Phoenix also includes a +5mm/-5mm reach adjust headset and four frame sizes (S1-S4). That allows riders to pick a frame size by reach from 430-525mm in 5mm increments.

Geometry alterations are also offered through a flip chip at the upper suspension pivot which raises the BB from the stock low position by 6mm and steepens the head tube angle by 1/2º.

Additional frame details

Other frame details include internal cable routing through the downtube using the Pivot Cable Port system, but note that there is no dropper post routing. You can run a dropper post, but you’ll have to use a wireless dropper. The crankset is based on the Praxis Cadet HD with a Praxis PF92 bottom bracket and it’s mated to a Super Boost 157mm rear end. Even on a DH bike, Pivot was able to keep standard Enduro/Trail q-factors for better pedaling efficiency.

For brake rotors, only a 200/203mm rotor can be used on the rear. The front brake is speced with a 223mm rotor with and adapter to convert the 200/203mm post mount.

Frame protection is provided through a large downtube protector with an equally large Tailgate pad to protect almost the full length. There’s also a molded chainstay/seat stay protector and integrated fork bumpers.

How much does it weigh?

In the S3 size with cranks, the frame weighs a claimed 11.29 lbs (5.1kg). The Pro build weighs 35.36 (16kg) and the Ride build weighs 35.98 (16.3kg) (all claimed weights).

Pricing & Colors

Pivot Phoenix DH frame kits will be offered for $4,799 with a Fox Factory Float X2 shock, Praxis DH-9 crankset, and the dual-idler pully assembly and chain. Complete bikes with the Ride GX DH kit will sell for $6,899, while the Pro Saint build pushes to $8,499. All are available in Black Gold or Red Mint. Available now.

Check out the Pivot site below for more detail on spec. You can also look for the new bike at the last DH World Cup of the season, this weekend at Mont-Sainte-Anne!