Heavy on nomenclature but light on weight, the new Prologo Nago R4 Pas 3DMSS claims to be the lightest 3D-printed saddle on the market. It’s just 149g, but it stays heavy on performance and comfort features, too.

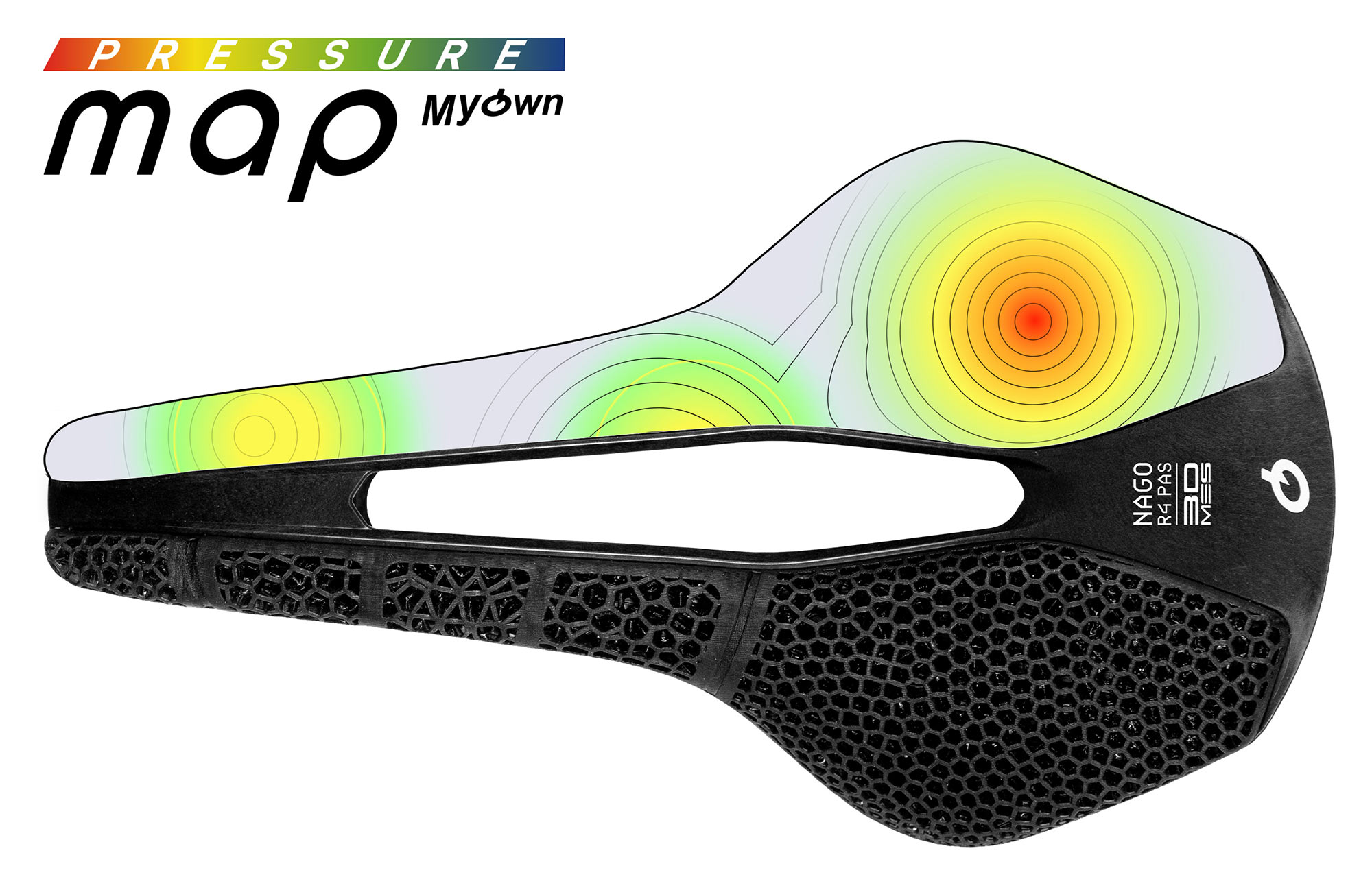

Using a three-zone construction, they print the cushioning with more or less support to cushion where it’s needed based on how and where you’re sitting on it:

Starting with they MyOwn pressure mapping research and experience with the standard Nago saddles, they identified three distinct zones. This “Multi Sector System” design is already used on many of their other saddles, including the excellent XC race saddle I included in my Editor’s Choice list for 2023. But those all use different foam densities to achieve the varied support.

Here, they use 3D-printed lattice structures to provide the different support levels. The material of each zone has different elastic coefficients, too, so it’s not just the shapes that vary.

It uses their T-shaped Nack profile, measuring 245×147 mm, with a full-length center relief channel and cutout.

The base is injected long-fiber carbon, which is lightweight and has just enough flex to keep it comfortable. The Nack (Nano Carbon Fiber) rail are carbon fiber with Kevlar and aluminum filaments for maximum stiffness.

The Prologo Nack R4 Pas 3DMSS will be available in April for €420.