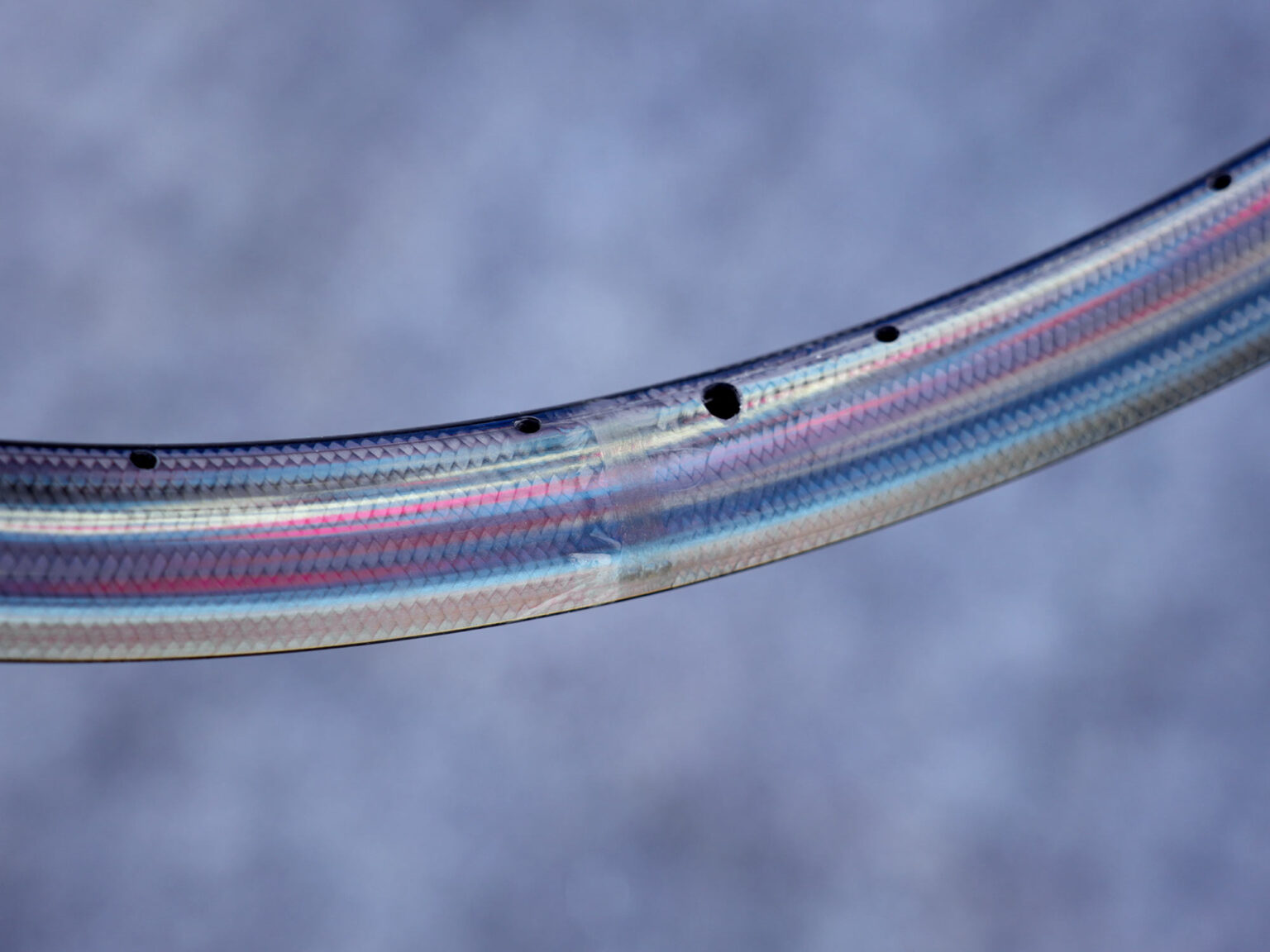

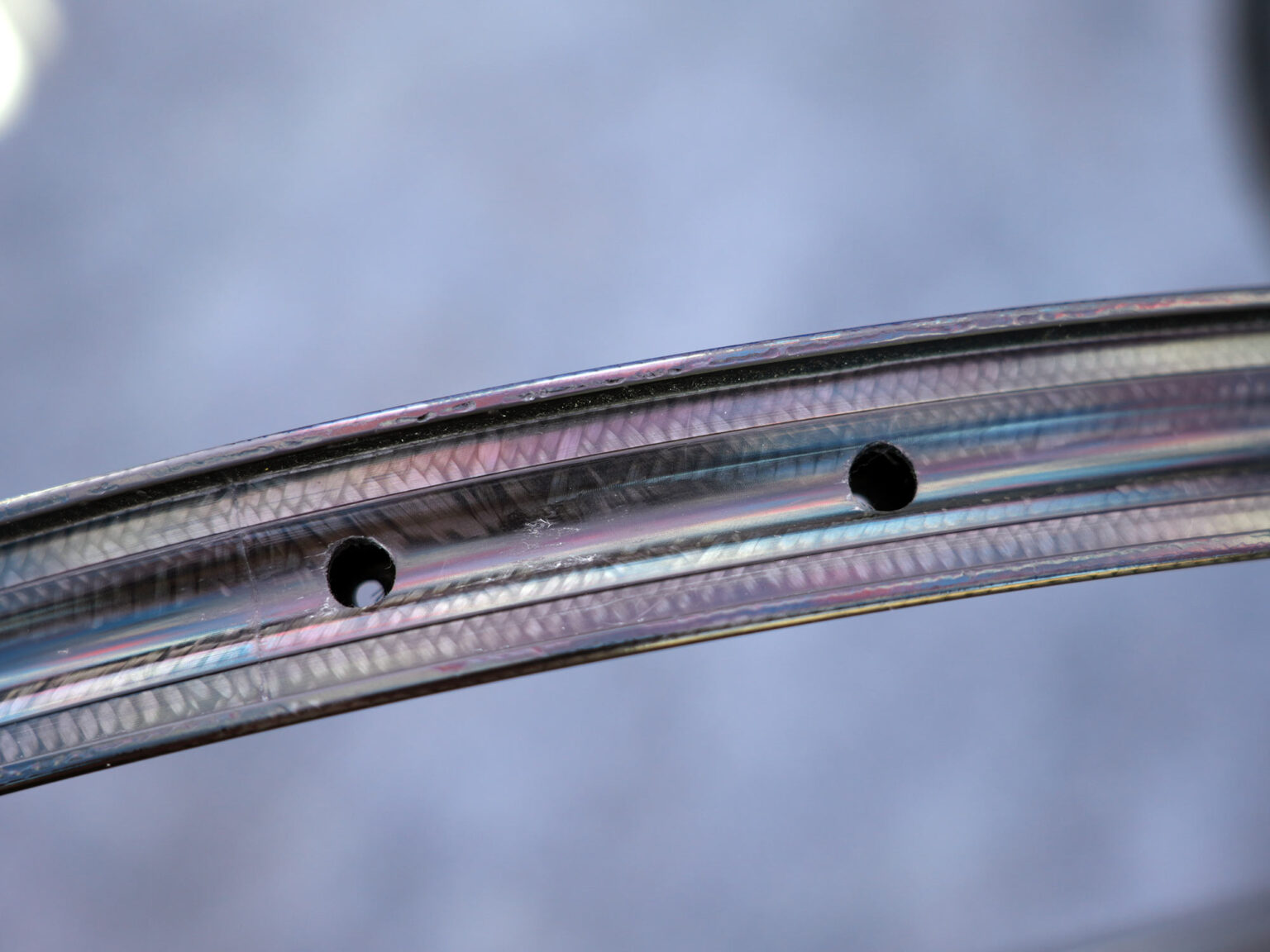

Just before Sea Otter, Munich Composites announced the opening of a new factory in South Carolina where they’ll make woven carbon fiber bicycle rims using resin transfer molding (RTM) construction. Boyd Cycling founder Boyd Johnson is part of the group that’s bringing them here and is the first to show off a prototype rim and “sock” using the technology.

While these are early samples, they show off some of what’s possible with the technology. The rim’s main structure is woven as a tube, which gives them a high degree of control over fiber placement, type, and eventual thickness.

Then other carbon fiber sections can be added where needed during layup, but the overall structure is one piece with continuous fibers running all the way around the rim.

The “sock” is dry carbon, but can be laid into the mold with pre-preg sections typically used in other rims or bike frames. Once in the mold, resin is pumped in under high pressure to soak the dry fibers, and heat helps cure it.

They also had the brightest outfits for the show.