Engin’s CNC’d mountain bike stems are about to get a new friend with their upcoming fully machined crankset, plus more sizes and colors for their seatpost collars.

The new cranks coming in Spring ’22, first in aluminum, but the end goal is titanium. But they’ll be really expensive, because they’ll take a really long time to make. Founder Drew Guldalian says that’s because they’ll be machined, and he’s doing it that way because no one else is doing it…in titanium, anyway.

The benefit will be that it’s one-piece, versus other ti cranksets on the market, so it’ll be extremely strong. Look for a lot of scalloping and trussing on the backside, which means lots of tools and time, but it’ll be bombproof. And, he says, within 10g of some of the lightest cranks on the market.

OK, but why make cranks? Drew says they were making the spiders for other cranks, then stopped, and then decided to start again but thought if they did that, they should just make a crank, too.

But another reason is that with so many parts in short supply, there’s ample demand for alternatives. And as we all know, there’s always a market for high-end, boutique parts that also perform well. Target prices are $450 for alloy, and $850 for titanium cranks, but final prices are TBA.

More seat collar sizes

Joining his original 31.8, 34.9, and 38.6 millimeter seatpost clamps are new 33.1 (surly MTB), 36.4 (Santa Cruz), and 30.0 (older Surly road bikes) sizes. They’re a taller design that spreads the clamping force across more of the post. So, you don’t have to clamp as hard, which makes them great for dropper posts where you could bind up the sliding mechanism by overtightening.

There’s also a new “Barbecue Black” ultra matte black color option.

The frame building jig is up

Another major project from Drew is his framebuilder’s jig. This work of art is designed to give handmade bicycle builders the highest precision jig possible, and it looks the part.

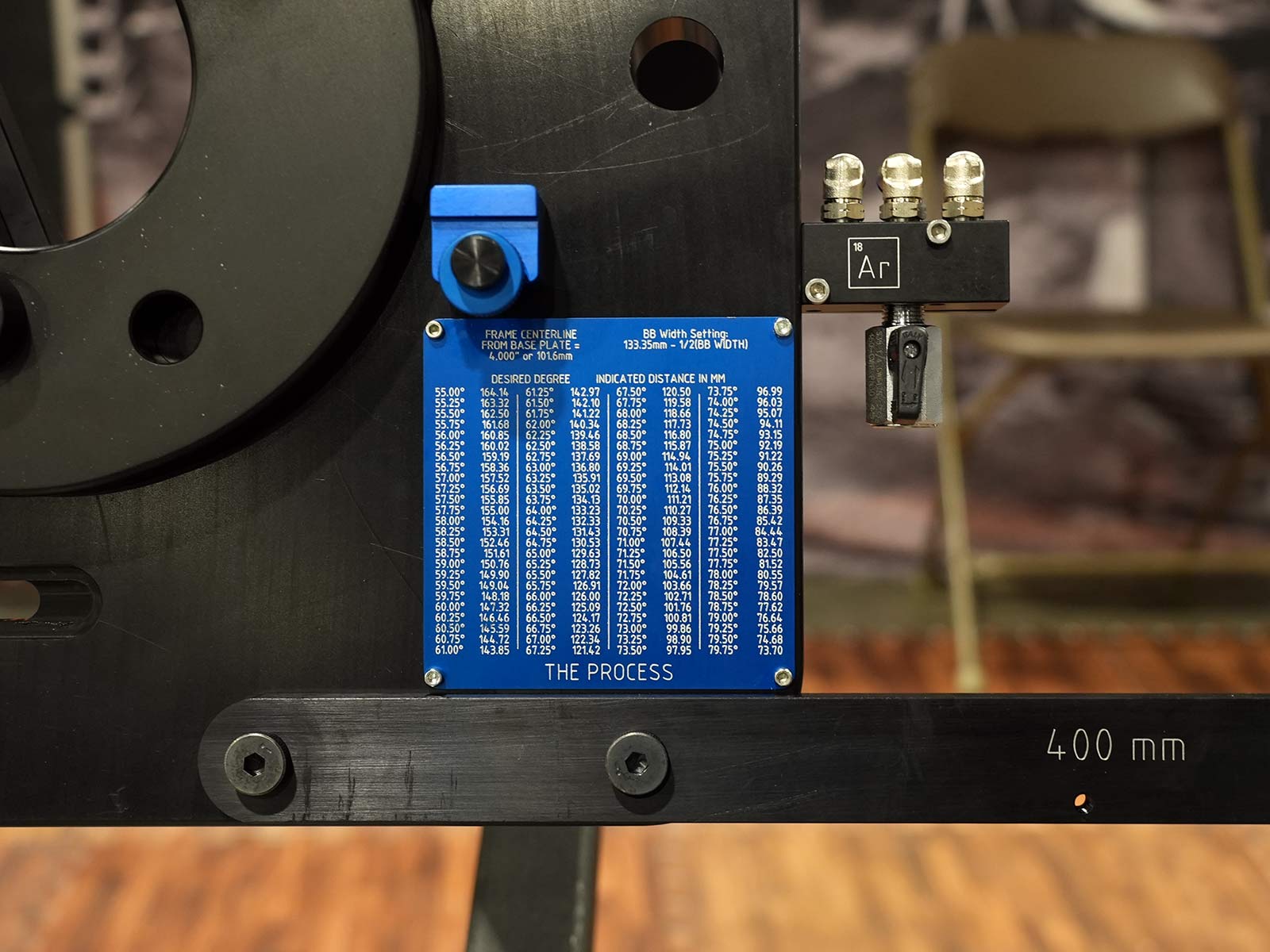

Called the Process Fixture V.2, it’s an updated model that has adjustments and guides for every part of the bike, plus built-in charts to aid in dialing in the geometry and angles.

Based on the Accuset Fixture from Bill Grove, the Process Fixture 2.0 is fully modernized for current disc brake, thru axle, bottom bracket, and headset standards.

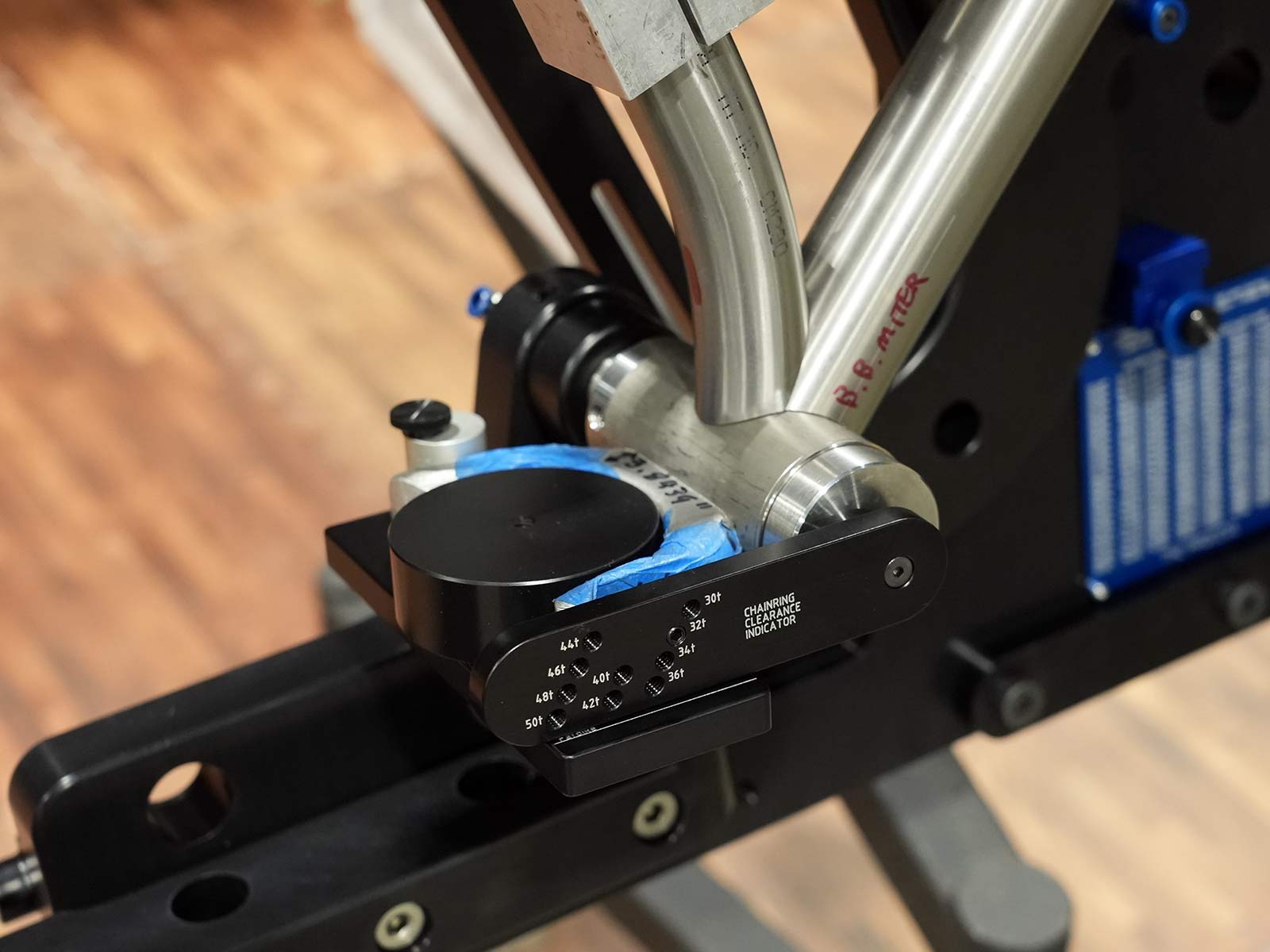

Every detail is considered, like a guide to show chainring clearance at the chainstay, so you can ensure your frame will clear the desired ring sizes. Everything is adjustable down to 0.01mm accuracy. It’s $9,500 all in, sold with everything you need. Check it all out on their website and get your order in…delivery is 2-10 weeks.