Princeton CarbonWorks rode out of the gate with an impressive looking freshman effort, using a sinusoidal wave pattern for their Wake 6560 aero wheels. It’s not just the shape that was interesting, though, it was the impressively lightweight for their 60-65mm depth and comparatively reasonable price points. Two versions are available, one for rim brakes and one for disc brakes, and we tested them both. Here’s how it went, starting with a brief overview of their tech and design…

Both versions use the same rim shape, which has a mixed depth of 60mm to 65mm. It’s an even wave, unlike Zipp’s finned shape, but the goal is similar. By creating multiple depths and profiles, it can be more aerodynamic in a broader range of crosswinds. Where others may stall at a certain yaw angle, these can overcome (or at least minimize) that by having some of the crosswind reattaching earlier. In theory that means a more stable wheel that’s less prone to erratic performance in crosswinds.

The rim brake model gets a well tested and proven high temperature (220°C Tg) resin and carbon mix (Toray 1.5k) from a factory that’s known for making other high end brands’ carbon rims. We can’t say who, but asked Princeton CarbonWorks’ founder Paul Daniels tell us off the record so we could put their claims into perspective. Suffice to say you know the names, and there’s a chance some interesting things could come out of that shared facility in the future. In their own testing, they say the highest temperature the rim brake surface achieved was 144°C with less than 0.07mm average expansion (0.3mm is the limit their manufacturer will accept as a passing grade. More expansion than that means the rim is becoming too soft from the heat and could fail).

The disc brake rims maintain the outer UD carbon layer all the way around since they need no brake track. Both rims have a claimed weight of 490g, and both are tubeless-ready and come pre-taped with valve stems in the box.

The hubs are a standard offering, nothing particularly unique or special about them, though they did spec a custom drilling for the straight pull front to get the low 16-spoke count they wanted (rear has 24 spokes, and you can request a 24/24 build at no extra charge). That’s not to say the hubs are bad, but they admit they’re a mostly stock item you’ll fine on other wheels out there. I had no issues with them, and they rolled smoothly with no noticeable play. Want something better? They offer an $800 upgrade to Chris King R45 hubs in your choice of nine colors.

The disc brake wheels use J-bend spokes in a 24/24 count. Both use Sapim CX Ray spokes with Sapim Secure Lock nipples.

Rim brake models come in QR, and disc brake versions are Centerlock with thru axle and QR options.

The wheelsets retail for $2,400 (rim) and $2,600 (disc) and include tubeless rim tape, valve stems and padded wheel bags. Either version can be upgraded to Chris King hubs for $800. Stock builds are Shimano 11-speed freehub bodies. Campagnolo freehub bodies are available on request, and SRAM XD-R can be custom ordered.

Actual Weights & Measures

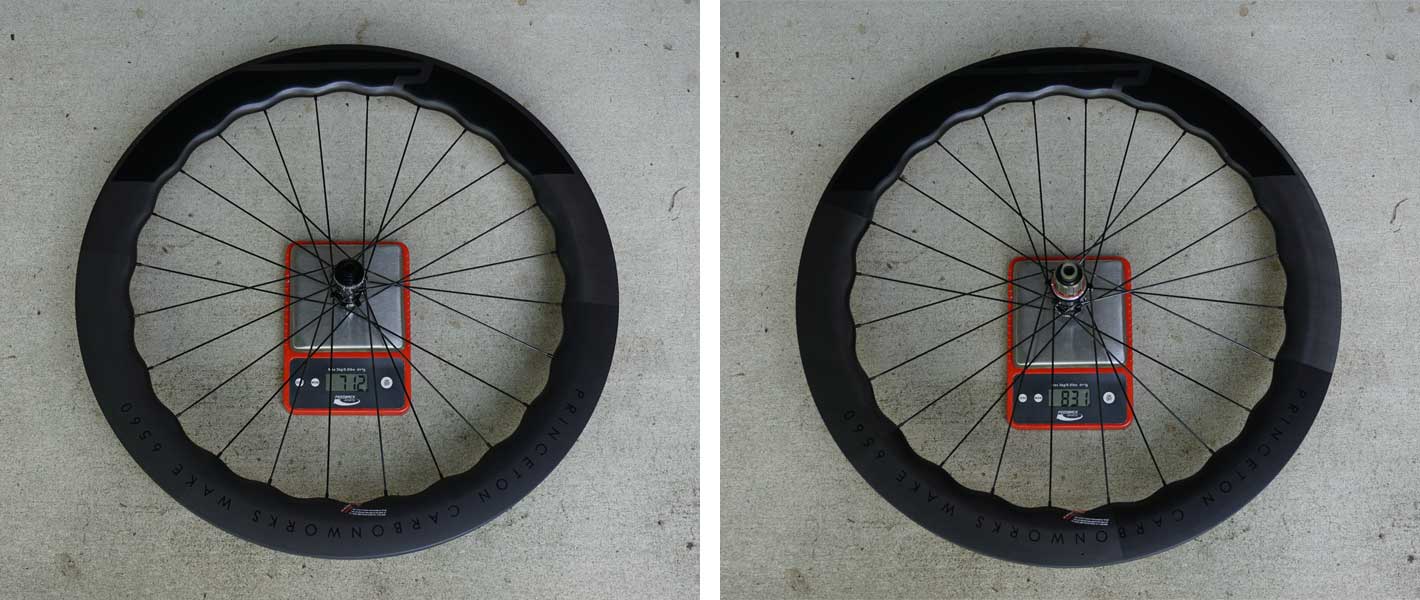

The rim brake wheels, with tubeless tape pre-installed, weighed in at 651g and 828g for a total of 1,479g. That’s really good for a wheelset this deep.

The disc brake wheels with 12mm thru axles and tubeless tape weighed 712g and 831g for a total of 1,543g. Still really good. I asked how they were able to build 60-65mm deep rims that weigh just 490g each and they say part of it is using a really good manufacturing partner, and some is their secret sauce they’re not ready to reveal. Claimed wheel weights are 655g/840g (rim) and 705g/845g (disc).

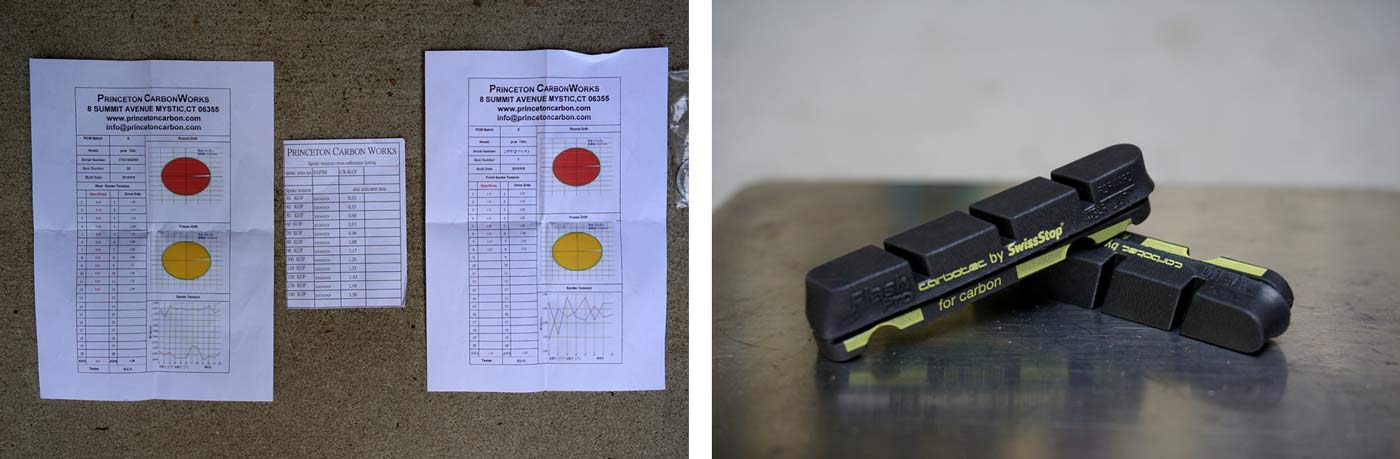

Other parts in the boxes included skewers (86g), deep tubeless valve stems (11g) SwissStop CarboTech brake pads (30g) and a spacer in case you want to put a 10-speed cassette on there (4g).

They also come with a complete readout of spoke tension and wheel build particulars.

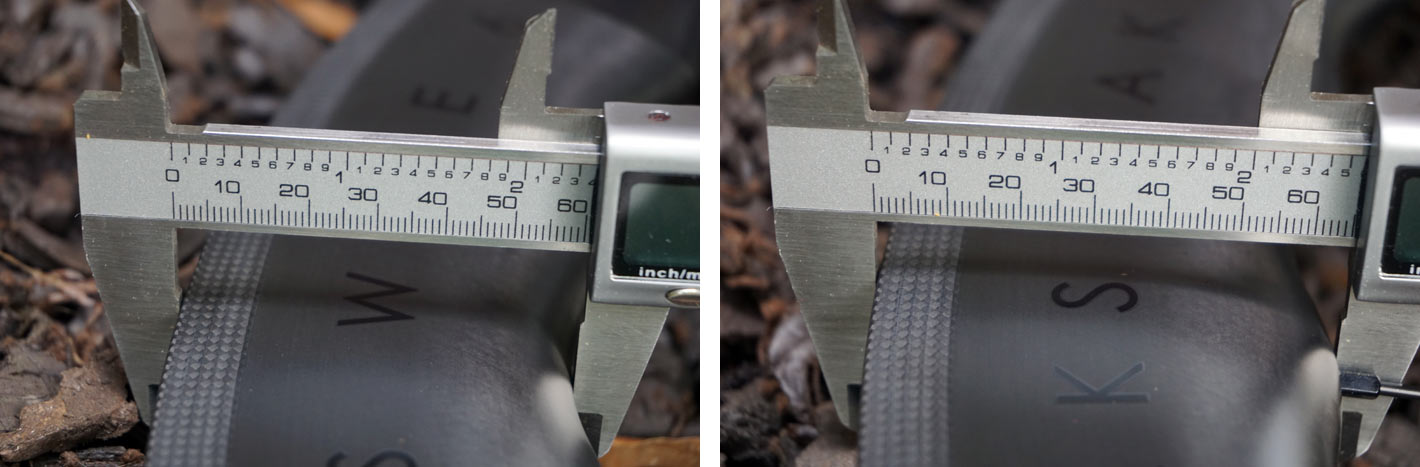

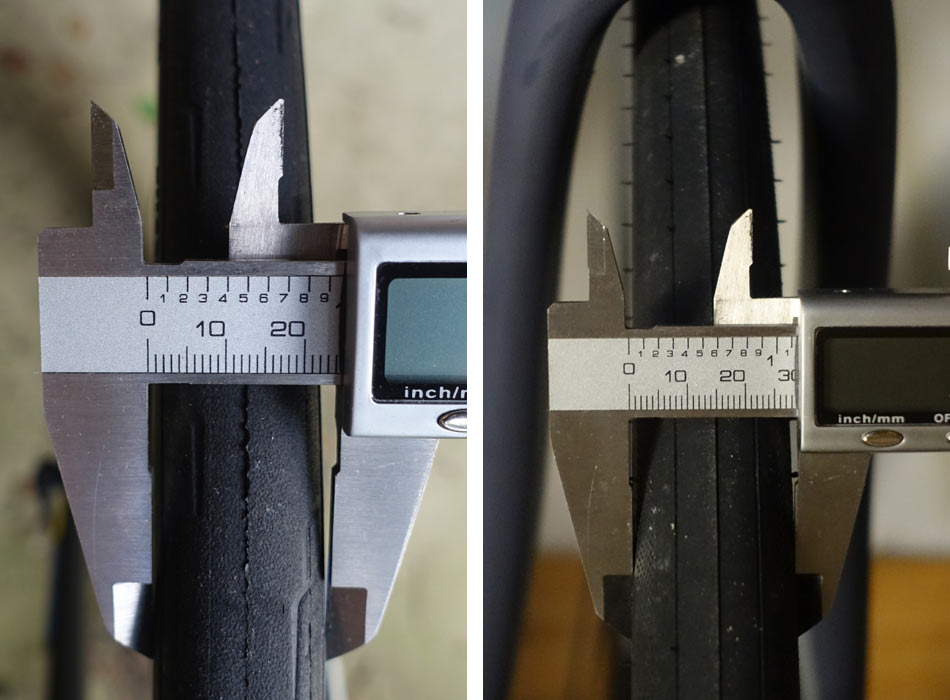

Depth measurements matched spec at 60mm and 65mm.

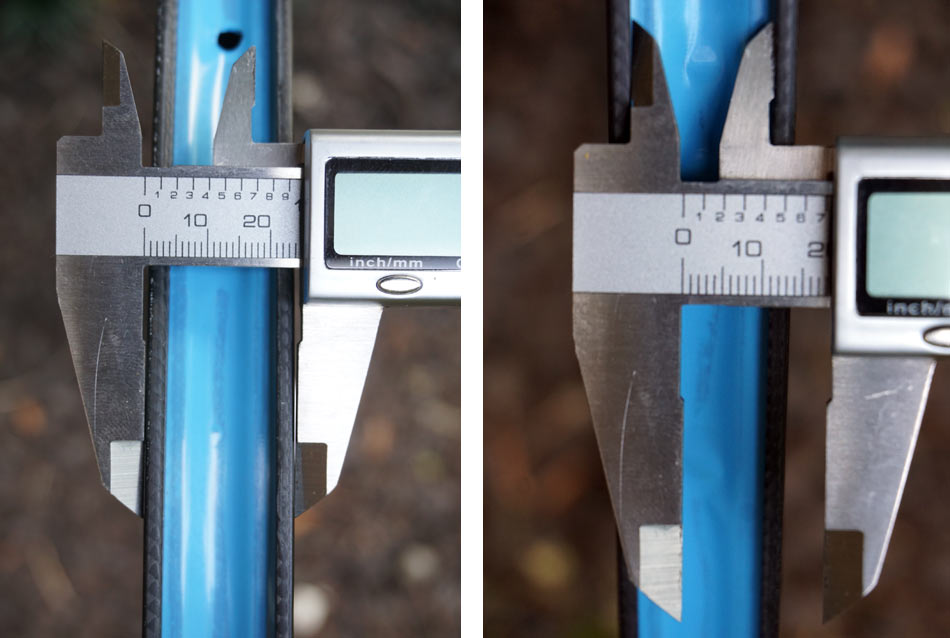

Both rim and disc brake rims measured the same with 24.5mm external and 18.5mm internal widths. Claimed widths are 18mm internal and a max 26mm external, which is slightly below the brake track where we measured.

Princeton’s wind tunnel testing found that 23mm wide tires were the most aerodynamic (for their rims), so that’s what they recommend for optimum aerodynamics. As such, I tested one set (rim brake) with Kenda 23mm tires with a tube in them, and I put Hutchinson 28mm tires set up tubeless on the disc brake wheels. The Kendas measured 24mm wide once installed and inflated, and the Hutchinsons at 28.5mm, both well within expected tolerances.

Ride Review

As luck would have it, we had moderate crosswinds during our short test period with these wheels. One of my frequent routes is a mix of curving roads past open pastures, and they turn to head in every direction. If there’s a wind angle that’s gonna suck, I’ll find it on this ride. There’s also a healthy mix of rolling hills and a couple short punchy climbs perfect for standing grunts or sprints.

In a headwind, the Princeton CarbonWorks Wake 6560 wheels feel like any other aero wheel. They’re fast and slice through the air nicely. But they sound different. As rims get deeper, they can develop a fvwoom-fvwoom-fvwoom sound as you pedal along, especially during a sprint. These were pleasantly absent of any such hollow sound, remaining extremely quiet in all situations.

The best I could come up with to test their stability in gusts was riding country roads back and forth past our local quarry where dump trucks routinely rip past at 50+mph. You know how when a bus passes you and you get that gust of wind that wants to push you off the road slightly? This is worse, even though all of the truck drivers I’ve encountered on our roads are very courteous with the space they give when passing (and patience when they can’t), they still go fast. Both oncoming and overtaking, these gusts mimic what it can feel like when the winds are higher and more erratic. Here, the Wake 6560 wheels did move, as any wheel would, but they recovered quickly and didn’t overreact. From a performance standpoint, this means a more predictable, safer experience.

I also bombed down a high speed descent in a curve with crosswinds. I topped out at 41.6mph during my test and the wheels were perfectly stable.

One thing that surprised me was how comfortable the wheels were. Typically, deeper carbon rims can ride harsh because they need to be made stiff. Not these. Even with 95psi in the 23mm tires (I weigh about 194lb fully dressed and ready to ride), they weren’t harsh over potholes or expansion cracks. These were tested on a Look Huez, which is a lightweight climber’s bike that makes no particularly big claims of comfort. The feeling was similarly smooth on the Cannondale Synapse, a bike that is designed for long distance comfort, with the disc brakes wheels and larger tubeless tires. Well, actually, it was a lot better on the latter setup, but still worth a compliment on the former.

To test rim brake performance, I used our local parking deck’s circular exit ramp to drag brakes at the highest speed I could for two consecutive runs. The first descent was about 60 seconds of continuous dragging followed by an immediate stop. The second descent was at higher speed and lasted about 44 seconds. On that one, I let off the brakes long enough to get four complete pedal revolutions at full sprint, then stopped as quickly as possible. Both situations ended with mimicked emergency stops from high speed. Both felt controlled, predictable and seemed well within an acceptable distance. Granted, this isn’t the same as dragging the brakes down a mountain side, but it’s a reasonably real world test for any area with rolling hills. Let’s be honest, if you’re climbing bigger mountains, you’re probably not climbing with 60+mm deep rims, either. Which brings me to their climbing performance…

Which is surprisingly good for a rim this deep. There are some wheels whose weight can be felt (tires play a huge role in this, too, but all else being equal…) when climbing and accelerating. A wheel’s rotational mass only needs to be overcome when changing speed, which describes climbing pretty well since gravity is always tugging us back between pedal strokes. For a rim this deep, I felt negligible additional effort to power them up the hills. I’d still choose something shallower for big days in the mountains, but if your rides consist of lots of flats with some climbing, these should be an easy decision.

The only complaint I will register, other than the shoddy rim tape application, is a bit of lateral flex under standing efforts, as determined by the rims making contact with the brake pads. To be fair, I had the pads set closer to the rims than they should have been, and most wheels I’ve tested do the same in such situations. But I felt obliged to mention it since I could easily induce pad rub by leaning the bike to either side. I did not notice any rubbing during cornering, though. And I didn’t notice any rotor rub on the disc wheels.

This was a short term test, per Princeton CarbonWork’s request, so it’s based on a few rides on each wheel set. As such, I can’t speak to long term durability or wet weather braking performance for the rim brake models. I’ll update if/when I get them out in the rain, but if you routinely ride in the wet, my hunch is you’re either not riding carbon or already on the disc brake upgrade path.

First impressions are really good. They seem to deliver on the promises of lightweight and predictable, fast performance in a variety of crosswind situations. Throw in fair pricing and their smooth, quiet ride and I’d say this newcomer is on the right track. Worth a look if you’re seeking more speed without sacrificing handling.