After testing the concept for years on frames built for him and his wife’s personal use, Dave Turner introduced his first production cyclocross bike in April this year, just prior to our closeup look at Sea Otter Classic.

Then, just prior to the current cyclocross season, we had a couple weeks to ride one around our local gravel paths, ‘cross training loops and trails. Unfortunately, they needed it back before Interbike to use as a demo, so it didn’t see any racing action, but we packed in as many hard, fast and jumpy rides as we could to test the alloy frame to the limit…

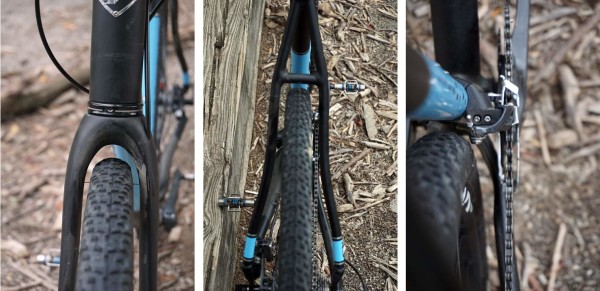

The Turner Cyclosys uses a butted and shaped 6061 T6 aluminum frame paired with TRP’s carbon cyclocross fork. From a distance, it looks fairly standard, but closer inspection of the details reveals its finer points that separate it from price-point alloy bikes.

A 44mm headtube is the darling of the small builder community, allowing virtually any combination of headset type and fork steerer shape. Here, you’ll find a tapered carbon steerer with external lower headset cup and a Zero Stack upper cup that lets you get the stem almost slammed if you like to get low when the whistle blow. Shifter cables and rear brake hose all enter the frame on the downtube, which puts them out of the way of water, dust and dirt. It also keeps them from rubbing on the knee when standing to sprint, something that can be an issue with cables entering too far back on a headtube.

The bike uses a PFBB30 to allow for the larger diameter, lighter weight crank spindles. Our test bike used an adapter bottom bracket to fit a Shimano 24mm spindle, but the stock build available for order is SRAM Force with a proper 30mm crankset. This BB shell size also lets you run an eccentric BB to set things up singlespeed.

Asymmetric chainstays put an oversized tube on the non-drive side for additional stiffness. Combine that with the flared shape of the seat tube and you’ve got very efficient power transfer. Fortunately, the seat tube’s flare morphs to round just in time for a standard front derailleur clamp. So, if you’re running a 1x, you won’t see any unused mounts or adapters on the frame – very clean.

Out back is a 12×142 thru axle with a massive dropout/derailleur hanger piece. It’s replaceable, but it’s also very overbuilt and should hold up to more than a few spills.

Post mount rear brake mounts are positioned to minimize their appearance and tuck the caliper neatly inside the rear triangle.

Tire clearance is billed at up to a 700×43. With the WTB Nano 40c tires, there’s plenty of room for mud and debris to find their way cleanly through the frame and TRP Carbon Cyclocross fork.

The top tube is shaped into a shoulder friendly profile in the middle.

The complete bike will come stock with a Thomson seatpost and stem, Zipp handlebar and Cinelli bar tape. Our demo bike had more than a few non-standard bits on it. Stock wheels are Stan’s Iron Cross with Schwalbe X-One tubeless ready tires on them, not the Stan’s Valor Carbon and WTB’s shown here.

Complete bike weight without pedals in size XL was 19.53lb (8.86kg).

RIDE REVIEW

The solid frame, fork and wheelset combo was sturdy in the fast swooping corners, holding the intended line. And it stayed stiff and strong on the climbs and sprints, too. The curvy lines belie its sturdy workhorse abilities.

And the tires let it roll over everything, chasing down bikes with 33mm tires over the rough stuff without breaking stride. Even they commented how much less effort I seemed to be putting into handling over the really rooty sections, catching them with utter ease. To be fair, a lot of that has to do with the larger 700×40 WTB tubeless tires absorbing their fair share of the bumps, but the bike was able to handle the additional speed with no quirks to detract from it.

Those oversized tires, which would be illegal in any UCI-sanctioned race, may have also cushioned the expected harshness from an alloy frame with large seatstays. The Cyclosys, as spec’d (and Dave was very excited to spec the new 40mm WTB Nano tires), was a smooth ride. I’d suspect narrower tires would transmit more ground imperfections through to your arse and wrists, but that’s racing. Put these bigger tires on for everything else and it’s awesome.

They also mitigate the impacts…

…of big jumps…

…and hard landings. Click to enlarge for dirt spray landing sequence. If it were video, you’d hear the most horrendous ever brrdrdrdattt sound of tires squirming under low pressure. Surprisingly, they didn’t burp any air and stayed on the rims just fine.

My only grumbles were occasional toe overlap with front wheel, possibly partly due to the larger tires installed, but I was also riding the XL…which has a 575mm ETT. Normally, I’m riding more of a 585mm ETT, but a) the 2XL frame jumps to 590mm, and b) the 2XL frames weren’t in stock yet. That, and there’s no clearance for a Stages power meter between the crank and chainstay, so you’ll have to find alternate means of measuring power output if you’re into such things.

For those with an alloy budget, the Turner Cyclosys makes a fine option. I rode it plenty of miles on the road between trail and path sections, and plenty of miles off road, too. All were enjoyable. The high speed handling suggests it’d make a great partner in your ‘cross crusade as well as a trusty companion on all day exploratory rides, too.

Frame sizes run XS through 2XL, all available now. Frame & fork combos retail for $1,499. Complete bikes with SRAM Force run $3,712 with your choice of either 1×11 or 2×11 Force groups (hint, take the double, then simply add a 1x chainring and remove the cable and front derailleur…at least then you’ve got the front shifting parts for later). Upgrade either the frameset or complete bike with Stan’s NoTubes Valor carbon wheels for $1,403 more. Available in Black/Sky Blue as shown here or Raw Metal with black graphics. Custom powder coat colors are available for $150 more.