Last but not least, we have Drew Guldalian of Engin Cycles. Drew’s product is exciting from a deeply technical standpoint – he’s a crowd favorite for the bike engineers in the know. His bikes are highly process oriented (#itsallabouttheprocess) so it really takes understanding his workshop to know the technical feats of his frames. His frames are of high quality because he’s got a top notch shop packed with fabulous machinery and he knows how to use them. He CNC machines his complex and ultra-functional dropouts in house – as well as much of his tooling (which he occasionally opens up for sale to other builders).

In this final and late installment of the Bikerumor Builder on Builder Philly Bike Expo interview series, Drew is interviewed by Bryan Hollingsworth of Royal H.

BRYAN: You own a retail bike shop (Wissahickon Cyclery) in addition to building Engin Cycles- how do you find a balance between the two?

DREW: I am not sure if I have found the balance! I work six days a week (definitely would not have thought that would be true after 22 years) and have rather consistently struggled with this very thing. If the bike shop is running smoothly, the frame shop runs smoothly. If the bike shop is having employee issues, the frame shop suffers since I am the only one working in there. I have said many, many times the hardest part about being an employer is being an employer. Finding good employees who have a love of bicycles and want to work hard is not easy. Add on the issue that I do not teach anyone who works for me how to make frames, and that is just another handicap. Currently though, I have what I feel is the closest thing to an A team. We have a great crew–honest, hard-working, and best of all we all get along very well. The future looks very bright.

BRYAN: Obviously you don’t run the retail shop single handed, but have you ever had help on the framebuilding end?

DREW: As indicated in the last answer, I essentially am solo. I have in the past allowed some employees to help out, but ultimately my hands are the only ones touching the fabrication end of things. Bike shop employees have done some basic finish work during pre-bike show chaos, and assemblies are often handed off to the main guy in the bike shop (currently Vinny).. This allows me to get onto the next task at hand.

BRYAN: How did you get your start in the bike industry? Retail to framebuilding or vice versa? Or some new combination?

DREW: I started the bike shop with a dream in mind and a huge amount of determination. I was only 23 years old and about six months out of college. I lived on the cheap for way too long and just kept on making the place one notch better. I have always had a desire to make bicycles but needed to get in a better financial position before that journey began.

BRYAN: You do fillets, lugs, and tig- which did you learn first? What was the timeline for that?

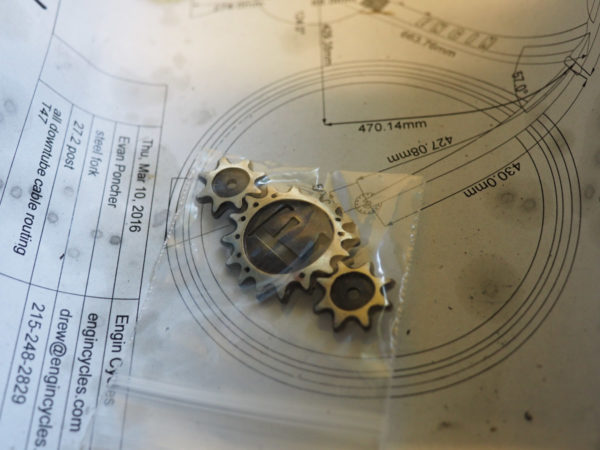

DREW: I learned to TIG weld first, but now I only do titanium bicycles so there are no fillets or lugs anymore. I just launched new branding, mostly because I felt my original head badge was something that lent itself to more classic styling and construction. Now that the bicycles are always titanium and more contemporary, often using parts of my own design, I felt the badge needed to change. I know it will upset some folks but I needed to move forward.

BRYAN: What motivated you to add titanium as a tubing option?

DREW: I drank that Kool-Aid long before I started making them. I just needed to get some other stuff out of my system (i.e. lugs and fillet brazing!)

What’s the most exciting thing road bikes have adopted from the mountain bike scene?

I kind of feel that nothing is really ‘new’, but as grinduro-style bikes get more popular I think the tubeless tire system is a must. I would never have a bicycle with inner tubes again.

BRYAN: You designed and made some nice looking Engin dropouts – besides the obvious unique identifier this gives your frames, were there other things that motivated you to make these?

DREW: With so many years of being a mechanic, there are some really small details that I obsess over. Things like the derailleur hanger, clearances, brake locations, and so many others. Once I went to titanium only, it was a good chance to make the bikes mine and only mine by adding some unique touches.

BRYAN: You have a truly dialed in shop, but I imagine that happened over time – what was the tool that made the biggest difference in your process? In general, how has a well stocked machining operation changed the way you think about and approach framebuilding? Any machines you’re currently pining for?

DREW: I have to be honest and say the CNC machine was an eye-opener. It allowed me to make a bicycle so much more my own than I could before. Endless opportunities there. Unfortunately, my answer to question one pops up, and I struggle to find the balance between making more bikes and exploring all of the opportunities presented by the CNC machine. When I get an idea in my head, I really want to see it through, but that’s not always practical time-wise.

As far as what I’m pining for, I really want to get a CNC lathe. It would really help speed up my process. I think it would actually provide more time savings than the vertical machining center has, since I would use it for one-at-a-time parts as well as for batches. The VMC is more of a batch-making thing.

BRYAN: How would you describe the ideal Engin Cycles customer?

DREW: Patient!

BRYAN: What’s riding in Philadelphia all about? Are you a PA native? Where were your formative riding years spent?

DREW: I moved here in 1995 so I have lived here longer than any other place in my life (hint of how old that makes me!). The city is wonderful and since I have about 75,000 lbs of iron in my shop, I am kind of grounded here. The riding is spectacular and I can ride my bicycle to work on single track and only hit the road about 1/2 mile of a six-mile commute. Not bad for staying within city limits. I am originally from Princeton, NJ–so not too far away, but really another planet since it was New Jersey.

BRYAN: How do you deal with people from out of town constantly asking you for your opinion on Pat’s or Geno’s?

DREW: Tell them to go to Billy Murphy’s Irish Saloon in East Falls.

BRYAN: Pat’s or Genos?

DREW: Murphy’s!

BRYAN: Yards or Victory? Enough! Sorry.

DREW: Neshaminy Creek is killing it lately. I love their cream ale. Feel free to come over and enjoy one while you are in town.