When the SILCA SuperPista Ultimate landed on the scene in 2014, it was so beyond anything in its category that it simultaneously inspired outrage and confusion in the consuming public. Why should a pump be so special? Why the heck would anyone buy a $450 floor pump?

But for those familiar with Josh Poertner, the new proprietor of SILCA, it made total sense. Josh had helped to not only establish the carbon wheel category during his time at Zipp, but effectively challenged the upper end of that category throughout his time at the company – the Ultimate pump was just Josh doing what Josh does.

In this phone interview, Josh talks about getting started, his transition from high-performance racing components to the timeless, heirloom-quality tools he now designs and produces to interface with them. (Also, for full disclosure and interview context, I used to kind of work for the guy as an engineer, so there is some of that in the interview too)…

BIKERUMOR: How did you get into bicycles?

JOSH: I have to start all the way back there? I guess the short story all started with a Bicycling magazine. It was the Greg LeMond on the cover ‘89 Tour Issue. What struck me was that bike… wow. For me, it’s always been all about the product. There was a bike in there with Delta Brakes, those beautiful Delta Brake photos did it to me.

From there, I started riding my cheap Raleigh, trying to go faster and faster. Got a subscription to Bicycling and like everybody I learned how to lose weight in 12 weeks! All those things, right? How to climb faster. How to eat better. I did all that for a year. Then I saw an ad for an MS 150 ride. I signed up, raised the money and halfway into this thing (75 miles), I’m just this kid suffering out of my mind. I had one water bottle and no food but I was in the second group hanging for dear life. Eventually one of the guys in the group said,

“You need to drink something or you’re going to die. Have you ever done anything like this before?”

“No.”

And it kind of went from there, he was a local race promoter, knew the scene and a year later I was racing at a high level.

Then, when I was a Junior in high school my family moved to Minnesota. I was always pretty good at math, so I had sort of run out of math to take in high school. So they let me finish high school at the University of Minnesota. I met Dan [Casebeer] at Grand Performance and he made a deal with me, “Hey, get your classes in the morning or the evening, work whenever you’re not in class, and then just commute on your bike and that can be your training.”

BIKERUMOR: And then you can race for us!

JOSH: Dan was just such an amazing character in life. I’d never come across a person like that, who was so willing to see the world from your shoes and to put something together to make it work for everybody.

BIKERUMOR: You gotta give shoutouts to people like that.

JOSH: It’s amazing. He was doing things at the time, this was ‘94, ‘95, he was trying to start a junior development thing. He was doing this women’s ride series- he identified that women coming into the sport new were nervous about showing up to the traditional shop group ride because we all know what that can be like. A lot of places in the country are just getting there now – Dan was doing that stuff 20+ years ago.

I needed access to bike parts. I needed to make some money. I had to finish school. And I had to train. That he was willing to make that all work out was amazing. The Grand Performance of that era – my god, Bjorn Carlson was there, he was a former National Team mechanic, a real ninja. Dave Delanoy was there; he did five years in Europe racing for teams like GAN, Dan was an ex pro, Walter Croll was building amazing bikes for the team… Eric Noren was then a young welder at Croll who’d hang at the shop… It was just an amazing place.

When I got my contract to go to Europe, Dan gave me a list of phone numbers of people to talk to. One of them was Joe Parkin. I remember calling this number being, “Hi, Mr. Parkin! I got your number from Dan.” The information bestowed in those phone calls, you can’t learn that anywhere. Like “never take a water bottle from anybody.” All that stuff- you get off the phone thinking it can’t possibly be like that, and then you go there and you find out it’s completely 100% accurate.

BIKERUMOR: How many times have you seen “Slaying the Badger?” Fifty? Cause I have.

JOSH: So good! LeMond was my idol as a kid and watching that really brings it all back, not to mention what that guy has gone through!

BIKERUMOR: So you weren’t excelling at racing in Europe and then there was all this scary stuff on top of everything.

JOSH: I was good enough to go. Not good enough to stay. And it was the mid ‘95-’96. We knew stuff was going on, but that era there was pretty unbelievable. A week in country at my first race, and guys are injecting things in team cars right there in the parking lot. It wasn’t even hidden. It was everywhere. It was another universe. I went over there as a reasonably accomplished racer and I couldn’t even finish races! The speed – I’d never seen anything like it. Nothing else to say about it. So that clearly was not a career path for me.

So I came home, went to school and got my engineering degree and thought I was going to do big things in in car racing, but met Andy [Ording] and fell back into bicycles.

BIKERUMOR: You accidentally walked into the honey trap that was Zipp Speed Weaponry, right down the block from the Indianapolis Motor Speedway.

JOSH: Exactly. I had experience with all the cycling stuff and was hungry to do something cool. Andy had just bought Zipp and they were trying to reestablish that brand as something new and cool. It was just such a perfect storm right there in Speedway.

BIKERUMOR: How do you want to talk about Zipp? Zipp was really the big leagues – arguably the dream job of any engineer who likes bikes. And you did such amazing work for them.

JOSH: It definitely wasn’t big leagues at first! For a while it was me and Todd Winget who is a real life MacGuyver doing all the engineering… and machine building and everything else.

I think we did a very good job of appearing to be much bigger and more powerful than we were. I think a lot of that was Andy O’s management style. Just one of those people that could so quickly convince everyone involved with something that it was going to be successful. A lot of the best stuff we did at Zipp were in the periods where we had the biggest constraints. Time constraints. Cost constraints. You couldn’t just solve problems with money. You had to develop the idea that was out of reach, but realistically out of reach. Then you had to really pull it together and execute it in really tight timeframes. In the end, we were making our own machines and tooling to build the products we wanted to build and the creativity and problem solving just really fed into itself. The feeling of it is so empowering.

In a lot of ways, the beauty and the power of Zipp then was the real single-mindedness that we had to succeed and we had to do big things. That allowed us to really blow up a lot of conventional wisdom. I look back – we had some projects that we were literally bringing to market in four months. That just doesn’t happen! I look back and think about it – with hindsight, I don’t even know how we did it but we did it. I think therein lies the unique power of working under a unique set of constraints with leadership that really understands how to get to the finish line within those confines.

And as companies get bigger, that changes in really interesting ways. Like with SRAM, we had so much more money to do so many more interesting things, but the downside of that is…

BIKERUMOR: … the SRAM machine, which has policies and rules because they are so big. They have to. So things move slower.

JOSH: Exactly. With the scale of a larger company you have to move more cautiously and the complexity is far greater so you need systems and controls to keep it all in line.

I really appreciate my time at SRAM, we were able to do huge and impressive things, like the CFD project we led with partners like Intel, CD-Adapco and Fieldview. We won the Innovation Excellence Award at Supercomputing in 2012… think of that, a bike industry company sharing in a major award at the world’s largest Supercomputing conference! However, as much as I loved these things I continued to miss the small company days where we were just deep in it all day every day.

BIKERUMOR: In order for people to really understand the kind of cowboy development that was going on at Zipp… the rumor, the magic Josh Poertner story, is that you figured out, and then implemented in production, dimples for Zipp wheels for $500. In development, this is an insanely small amount of money, especially for something that’s just so transformative from a brand standpoint. I mean… Zipp is dimples.

JOSH: So officially, that’s a story the details of which we don’t confirm nor deny – because there is still some value today in how we did it. Again, that’s one of those magic of constraints things, right? I said, “Hey Andy, I want to do dimples on a disc and increase the stall angle, and I want to make a prototype” And he says “Great, can you do it for $500?” And I’m like, “Uhh..No.”

Then, you know, you go home and you stew about it, and once you get over your crankiness of not getting the giant bunch of money you want, you eventually come down to earth and you get really creative. One of my proudest moments was delivering the prototype of that project, which was a rideable carbon disc wheel with dimples in it… and under budget. Zipp was, in many ways, five or six years of stories like that happening over and over again. And it wasn’t just me, we ended up with an entire team of people doing stuff like that, we all believed anything was possible.

BIKERUMOR: And the other thing is that it wasn’t a place where you could just make price point product at the time. You had to have a case for it, a product had to have a reason to exist. It’s just very unusual in the industry.

JOSH: Absolutely. Product meetings all started with “Why are we doing this? What’s the Zipp angle?” That’s kind of amazingly liberating, right? We didn’t just get into aerobars, we made an aerobar that looked like the wing of an F1 car that changed what an aerobar looked like, features of that bar are still common and relevant. Similar thing with cranks. People forget, but we got into cranks with the first BB30 compatible crank, first sub 700 gram crank, that thing pioneered the 30mm spindle external cup and would go on to define the left hand bearing position for stuff that Cervelo was doing… it was the first road 4 arm spider and so many other things, 10 years ago! Then we made the first aero crank. I was very proud to read the Lance Armstrong/Ferrari transcripts and see Ferrari arguing with Lance to stop using the Zipp aero crank and start using the powermeter!! So there was this real desire to move into new categories and just completely blow the roof off of the technology. I think we still had that when you were there, no?

BIKERUMOR: Oh yeah. You scared the crap out of me. Like, “Make this seatpost. But it has to contribute to the dialogue.” And I’m like, “How the heck is that supposed to work? It’s a seatpost.” And you’re like, “If we’re gonna do it, it should blow minds.”

JOSH: Ha! I still wish we had made that aerobar you designed, one of my all time favorites!

BIKERUMOR: Wow, thanks! So on that note, so Silca becomes available and you buy this brand. Why this brand? What’s the point where you’re like, I’m going to leave this crazy Zipp job and go do this pump thing instead?

JOSH: I had been thinking about what I wanted to do next for a long time. I had started kind of sketching out the framework of a superbike.

BIKERUMOR: Because that’s your happy place. That’s your home.

JOSH: It was my comfort place. Then kind of out of the blue, David Morse left to start Dimond with TJ. He told me what they were doing, and it just took all the desire to do a bike away..I didn’t want to quit my life to go do the exact same thing, and in competition with my friend!

At the same time I was really getting into the supercomputing space, CFD, we were really doing some interesting stuff. SRAM was doing the eTap thing at the time which I really enjoyed having some input there. I liked how it was different, and talking about the user interface and the electronics, and the spaces where I didn’t have a ton of knowledge, where I was uncomfortable. So after 15 years of kind of doing similar stuff, it was time for something new, I realized that I was most enjoying the things that technically weren’t my job.

One day, Claudio calls and says he’s been trying sell SILCA and the company is in trouble. He was diagnosed with cancer, his health was failing, he was going through these rounds of chemo and radiation where he is in the hospital weeks at a time. And the whole time the company just fell apart. It was just him and his wife and they were teetering on the edge of bankruptcy and who did I know that he could talk to. “I’ll think about that and let you know.” Getting off the phone thinking, “Who the hell would buy-?” I love SILCA, and I love Claudio and I love my SILCA products, we sold the SILCA disc adapters at Zipp forever. But you just think, it’s such a crowded space. Everybody and their brother has a pump. Who would want that?

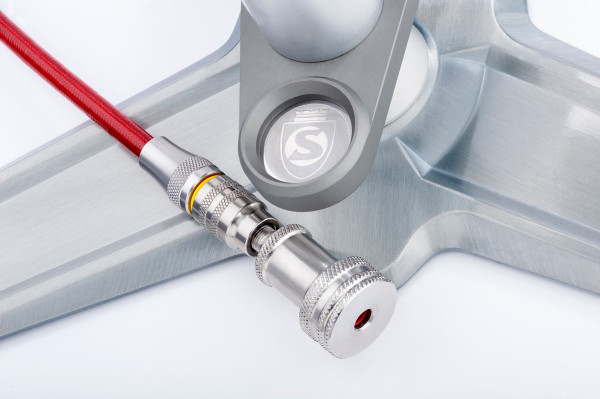

So of course, for the next five nights I’m unable to sleep thinking, “Why don’t ‘crack pipes’ work? We have all this technology but we can’t make a stinking disc adapter that will actually stay on the valve. Why do valve extenders suck? Why do we still have these problems?”

BIKERUMOR: That just never bothered you before? Why didn’t that bother you before? I feel like, surely, you must have thought about it.

JOSH: Totally, but you think in the terms of your core business – when I was started at Zipp, Andy had just bought the company and we were getting on our feet, our number 1 and number 2 customer service complaints were valve extender issues and disc adapters not working. And when I left in 2013, our number 2 and number 4 customer service complaints were… valve extenders and disc adapters. The reality is if you’re going to take an engineer and give them a project that’s going to take them six or nine months of study and research and design and execution… are you going to spend that on the next wheel? Or you going to spend that on fixing the disc adapter problem? Of course you’re going to spend that on the next wheel.

It was literally days of me laying in bed at night thinking about stuff. The year prior we booked 50 hours at the San Diego wind tunnel. The tunnel there has the work room on one side of the throat, and the control room is on the other, so when the tunnel is running, you can’t cross. You’re stuck.

You’re reusing the tires every time, a control tubie and a control clincher and then you have to change that tire for every test, so you’re always using the same tire. If the same person with the pump or the wheel walk out of opposite sides of the tunnel, you’re trapped for 15 minutes. At a $1000 an hour, that’s an awful lot of money.

We had lost a lot of time on a previous trip when the pump was left on the wrong side of the tunnel. At $250 per 15 minute run, it made sense to buy a couple of pumps to solve this. So we bought two beautiful shiny silver pumps that we thought were so awesome and we took them to the tunnel. So first thing in the morning we lose half and hour when we realize that the thread on chuck doesn’t work with the Zipp or Mavic valve extenders, so we have to change valve extenders and re-balance most of the wheels. Then, and I kid you not, by 4 o’clock on the first day we had stripped out the threads on one of the screw-on chucks, and then the door on the tunnel, has this latch that’s kind of sharp, we snagged the pump on the way coming out, on the one with the good chuck, and of course it’s not a fiber reinforced hose, so within one more use, the hose is blown out!

BIKERUMOR: Perfect.

JOSH: We search the internet, hop in a car, drive to the local bike shop. I buy two brass Silca chucks, by the end of the first ten hours with those two pumps, we had modified our pumps to have Silca chucks and one of them had a hose like 2ft long! So yeah, my $250 in pumps to save runs at the wind tunnel cost us like $1500 on the first day plus about $50 in SILCA parts! So that’s the first data point.

Two years prior to that, when we were developing the the first carbon Roubaix wheels we realized that the gauges we had on the three pumps in the CSC truck – between the three of them, they were off by 12psi in the 70psi range. They are only +-5% when they are new. But they are mechanical gauges, so impact, shock affects them, they are subject to fatigue. So literally, we had no data consistency and we were breaking rims based on what pump was used. Poor Fabian – one run good, next one he’s breaking his wheels. After the fact, we realize that on one of them 64 was actually 67. And if you used the other one, 64 was 59. That’s a big ass difference. So that was another data point.

BIKERUMOR: So you have these super elite racers and bikes and wheels, and all this development work you’ve done is undermined by this standard tool that nobody thinks about. And you’re up all night thinking about brass chucks.

JOSH: The thing that makes it so interesting though is that those stories are all things that I pieced together in the nights after talking to Claudio but, you know, it all happened years before. At no point was I like, somebody just needs to fix the floor pump problem. We’re engineers but that wasn’t our problem to solve. Every pro team we had after that, we’d get nice, calibrated high quality gauges or we’d control the pumps on the truck, in the moment it was a tactical advantage for us and our teams more than a bigger problem/opportunity.

And suddenly in that moment of thinking, who would want to buy a pump company? Well, you know, there’s actually a whole lot of room for improvement. And I think what really helped push me over the top was understanding that realistically there are only two companies in Asia that make pumps for everybody. One of the big secrets to Zipp that I don’t think gets enough credit was that Zipp could turn on a dime and move quickly and be different, because Zipp actually made almost everything that Zipp made. We designed and made the hub, the rims, the machines, the tooling…

So I realized that I understood the problems, and some of the solutions in this space… but then realized that if we could execute in our own way, outside of the standard suppliers in this space, we can do stuff that’s really different. Not just different but hard to follow, hard to copy – and then we had the mindset that you mentioned earlier, of allowing it to cost what it’s going to cost. We’re going to make it amazing, and somebody will buy it because it’s the best.

On top of that, you have all the design stuff that, for me, was new and different and fun and exciting. I get to make it heavy! And I can spend as much as I want making it look a certain way! And things like, the handle – you know, my fascination with cooking and nice kitchen knives. So I got to go learn about how they make kitchen knives and make a handle like that.

So the end is, you’re putting it together and you’re rolling the cost together and you’re like, wow, it’s really expensive. But it’s pretty awesome.

BIKERUMOR: Did you understand where it would be positioned? Or did you price it where it needed to be priced at?

JOSH: So I thought the market would probably bear twice the top of the current market. The most expensive pump I could find was $150. I thought the market would bear $300. The problem was solving all these problems piecemeal, making each part ‘the best’ made for a brutal cost roll-up.

There was a point where it was me and Shane, in my living room. We were just a train wreck at that point. We’d done all this work to solve all these problems, and when you put it together, everybody we showed it to was just, blown away. You put it in somebody’s hands and they go from from this perplexed look and then this giant grin!

We sat down and went “Okay, if we want this price, we’re going to have to kill features.” We just couldn’t do it. It just seemed like every feature was so critical and important and justified.

BIKERUMOR: So did you cut anything?

JOSH: You kind of go through those steps, like, “Man, the rosewood is really expensive… but man, the color and the beauty…” And of course, we wax it. It’s waxed instead of lacquered because as you use it, your skin oils get into that wood. It looks better a year on than it did brand new. The igus linear bearing in the top cap is the same bearing that Fox uses in their forks. It’s really expensive, but it feels like butter… had to have it! The list was endless…

Eventually we said, “You know what? It’s pretty awesome and it’s pretty compelling.” It was pretty terrifying. “We’re going to be three times the top of the market, and I don’t know how many people would be willing to spend it. But I’m willing to bet everything, house and everything else, that there are people who will.” And as it turns out, there were.

I look at our business today, a large percentage of the pumps we sell are $450 pumps with another $400+ of paint on them. Not only do people buy them, but people do unbelievably beautiful things to them. We have a guy in Texas who is doing custom turned wood for the handles with ultra exotic root woods. In some of those cases, the handles are hundreds of dollars. From the beginning I’ve said that we’re out to make working with your bike as enjoyable as riding it, and while that isn’t for everybody there are a lot of people who love the process of working with and on their bikes.

BIKERUMOR: I’m playing with my Ultimate right now.

JOSH: Exactly. People tell us all the time that they enjoy touching and using the thing even when they don’t need to, they mess around with it on long phone calls, pump their car tires. Sounds crazy but it’s a nice experience.

The key is using it, it’s about the experience. When we launched at Interbike, there was a kid, an 18 year old shop guy with a shop owner. The owner was just fondling and touching the pump like “Aw this is nice.” And the kid says “That’s so much money for something that nobody is going to see.” I hadn’t thought about it before then, but that’s such a huge aspect of why people buy stuff, right? That moment really helped us to understand the customer for this product – it’s not the next cool thing to impress your buddies on the group ride. It’s a thing that’s personal to you and your passion for the sport, for cycling. I think that is why people love customizing them so much, it’s a personal little pleasure for people to own and use.

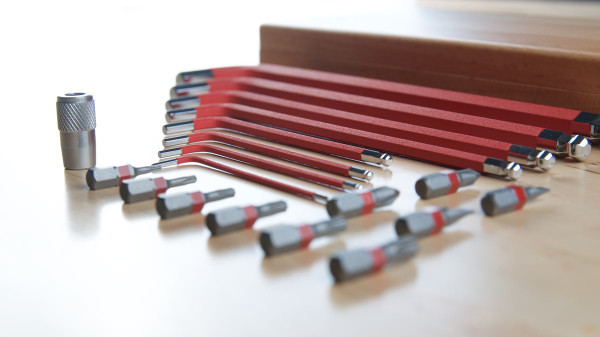

Sort of a similar thing with our HX-One. Pumps were one thing, but hex keys are the lowest of the low. They come free with half the crap that you buy, so our making really highly engineered and beautiful ones caught people by surprise, it was polarizing.

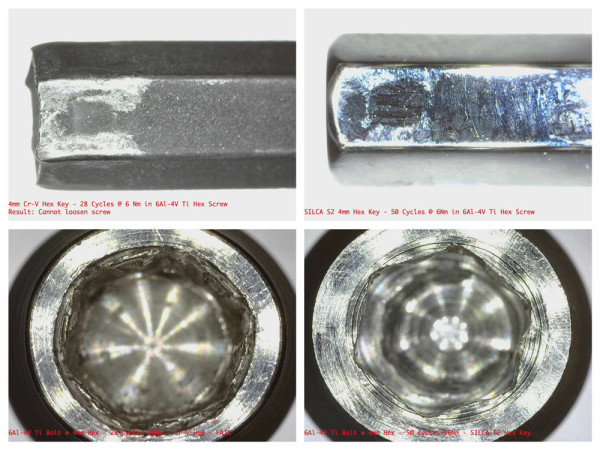

And yet you know from working in the industry that if you do titanium bolts with a hex head, you will replace hundreds, if not thousands per year for stripped heads. At 6Nm it’s really hard to strip a ti bolt. The problem isn’t the torque and it isn’t the bolt, the problem is the gnarly 15 year old mangled rounded hex key!

BIKERUMOR: I feel like you were in The Matrix when you worked product-side and you didn’t really acknowledge these things as problems. And then you stepped out from that and you’re like “Oh my god! None of this other stuff works!”

JOSH: Not once did we step back and go, “Someone should make better hex keys! Nor did we investigate the state of hex keys in the field.. I’ve found 3 way wrenches and hex keys in shops that were practically round, it’s like everybody’s trying to extract every last penny from the things, but at the expense of all these ‘warranty’ fasteners. We collected personal tools from ourselves and our friends and it was even worse! But from the product side, you think about the bolts, not the tools..

BIKERUMOR: No! No, that never crosses your mind. You’re just like “Hex keys suck, here, use Torx bolts.” It’s like this problem that can’t be solved… except that it totally can be!

JOSH: This is part of what I call the ‘Living room furniture problem.’ Why do we spend 4 times as much on the living room furniture when use it twice a year? But we go budget on the family room furniture and don’t replace it until the arm falls off of the couch.. I see this with tools all the time, we’ll spend $200 on a derailleur hanger alignment tool that gets used once per year and then round the hex head on the Ti Derailleur bolt two minutes later by using that free hex key that came with an Ikea set… 4 years ago! So we researched it and found that really exceptional hex keys do exist, so we set out to start there and go one better!

BIKERUMOR: I saw that bamboo box and I started giggling my head off.

JOSH: You would appreciate the work we spent on that- because my pet peeve situation is setting your brake cable adjustment screw. You pinch the caliper to the rim, and then, damn it, I have the wrong key!

We had this thing where you had to be able to open the box one-handed. Trying to get that balance right of the perfect magnet strength. Those little bits of joy where the magnet is strong enough that it won’t open carrying it around, but with one hand and a quick move, it opens just right! We probably made twenty prototypes with different magnet diameters and depths and strengths and different top and bottom ones to tweak that.

BIKERUMOR: I want to see your lab for this.

JOSH: Ha! The lab is the break room at Silca which is also the photo studio and also where everybody eats lunch, and also where the coffee machine is, but that’s great because it’s a congregation space where everybody gets involved. That stuff, it’s so easy to look at the product afterwards and go, “Oh that’s a cool feature.” You’re like, “You have no idea how much we suffered for that feature.” But it’s one of those things that I feel like if that weren’t the way it was it’s like, people wouldn’t enjoy it as much, it’s those little things that makes you smile when you use it, you know?

Same with the texture on our hex keys – we use this textured polymer coating. So the initial problem was that we use this thin-dense chrome, what companies like Oakley use on their lens molds. It’s the hardest most carefully controlled thickness chrome you can get. So we do that and realized these thin-dense coated hex keys are slippery buggers! Boom, down the rabbit hole and we’re dipping our fingers in NFS trying to pick up hex keys testing different coatings. Before you know it we’ve solved 2 problems..harder, more wear resistant keys and non-slip.

BIKERUMOR: You’re owning this space. Because of you, there is more expensive pump product on the way. What’s it like to have created the $500 pump market?

JOSH: It feels good, but it’s hard work. Similar in many ways to the really early days of Zipp, much of what we are doing is market creation, it’s doing something totally different and getting product in people’s hands so they can truly understand it and lots of education.

BIKERUMOR: But like Zipp, if you own your facility you can turn on a dime, right?

JOSH: We’re trying! We were two people 15 months ago. And now we’re eight. We’ve grown very quickly and we’re going 120 miles per hour down a bunch of paths, and now it’s harder to turn on that dime because the complexity is high. For all the flack we get about the price, the SILCA SuperPista Pump is 72 high-precision machined parts from more than 20 suppliers. Many of those parts are machined from high precision castings or forgings. So you think of just the supply chain for a part like that is really complex and expensive. So while we are driving full speed up there we are also innovating and working to hit price points that will put these products in the hands of more people, all while trying not to run out of stuff!

BIKERUMOR: Yeah. But at the same time, you’re pushing the edge at the top pretty hard.

JOSH: Realistically, our next tier down is still going to be more expensive than the most expensive other thing. Our layers, the way we do things is just by nature really complicated and expensive, the reality of tools is that better will always cost more, better tools need better steel which is harder to work with, better heat treat, etc….

BIKERUMOR: So how much does it cost to put these stripes in the cylinder? What’s their deal?

JOSH: Those aren’t exactly cheap, but they add something beautiful.

BIKERUMOR: It’s a detail you really need in there.

JOSH: If you take your pump and you flip it upside down and look at it in a different light, it looks completely different. They are machined at that coarseness specifically from one direction so they would reflect the light in a certain way. If you put two next to each other, one machined bottom up and one top down, you can tell the difference. We just found one much more pleasing than the other.

BIKERUMOR: I’m flipping my pump over and over in the light. This is hysterical!

JOSH: What I so love about this detail is that it’s a give-away that this isn’t just any aluminum tube, but it’s a porthole drawn aluminum tube with extra thick walls, so it’s an ultra precision tube. It’s finish reamed – basically polished to a mirror on the inside, so it’s a ton of technology and labor on the inside..so we add those stripes as a sort of indicator that this tube is special.

BIKERUMOR: Without those stripes, it’s not a luxury tube. It’s just a tube.

JOSH: There’s something about those stripes that are pleasing. It’s similar to the way a handmade suit will leave certain stitching exposed, it’s an outer sign of the craftsmanship on the inside and it’s there as much for the craftsman who made it as for the user who owns it. Even better, as the builders and painters paint these, is all the things that people come up with to put in the stripes. To come totally full circle – those are a constraint, every painter who gets one of these initially says “I don’t like these stripes. They’re textured.” I get it, if you’re a painter, those textured stripes are the last thing you want to deal with. And yet, every one of the painters we work with has come up with some way to solve the problem, and most of them will tell you that what they do in that zone is their favorite part of the finished product.

Thank you for noticing.

BIKERUMOR: No problem.

JOSH: You know I’ve been in this sport for a long time. I’ve had a lot of stuff. If I go in the garage and go through all the stuff from 25 years of being in the sport, almost nothing’s made it 25 years. I have a Campy t-handle wrench which is totally useless because it has a 6mm female wrench on one end for a waterbottle bolt when it was a hex-headed bolt. I have a couple of Campy tools and components that I’ll never get rid of because they are beautiful, and I have the SILCA pump that I bought as a 16 year old kid. And I have the Silca pump that my wife had when I met her (a true sign that she was a keeper!) and if we go on a family bike ride down the Monon to get ice cream, my daughter comes out and she puts the SILCA pump on her little tire and she pumps up her tire and my son takes it from her and does the same. How cool is that?

BIKERUMOR: You don’t even have one of your new pumps at your house, right? You only have your original ones?

JOSH: So I use the new ones all day in the office: we 100% check every pump by inflating a test fixture to ensure sealing and gauge accuracy. Plus we generally sell them as fast as we make them so I’d hate to take one from a customer’s hands!

You’ve nailed it though, we’re making lifetime products that you want to buy and use forever. Your pump will be more valuable to you in 20 years than it is today, just like my 20 year old pumps are to me. It’s a whole different outlook to the traditional model which is just a constant drive to displace and kill off what you had done before.

BIKERUMOR: Kill off your children… with new children.

JOSH: Sounds so terrible when you say it like that, but in a way, right?

BIKERUMOR: It’s exhausting.

JOSH: Yeah, but so is trying to sweat every detail to make something last forever! There is a whole new challenge of, wow, I look at my kids using my 25 year old SILCA pump, and aside from the hot pink and the decals, there’s a real timelessness to it and I have to live up to that! I think that was one of the first magazine things written about the pump, Pat Brady of Red Kite Prayer said “your kids will fight over this when you’re gone because you only ever bought one.” That’s awesome. That’s so what we were after.

BIKERUMOR: Yes! Inter-family strife! Nailed it!

JOSH: When you really think about it, the stuff you really lust over hard, new glasses, new helmet, new kit, and to a lesser extent the frames and wheels, numerous times in certainly my existence, it hit me that that beautiful new helmet that I was so dying to have because it was so awesome, or those sunglasses, that new jacket, those shoes, that lightweight thing – and then a year later the new colors or fit or style or lighter thing comes out and you’re throwing the original thing in the garbage. Done. Really 95% of the cycling stuff I’ve ever owned is landfill… that’s all of us I’m sure… nobody’s fighting over that stuff.

BIKERUMOR: My last question, which I’ve asked everyone in the series: what advice do you give the kid who wants to be you? What do you tell the next Josh Poertner?

JOSH: Be prepared to work because it’s beyond full time. It’s like 24/7 and for the first year, even when you’re sleeping, you’re dreaming it. And I would say go out and make the product that you want to buy. I think the key important word there is “buy,” because I think the landscape is littered with people who have made the stuff that they wanted to make or wanted to own, but there is this sort of – this is what I want to have, but is this a thing that I would have to buy. I think that if you can check that box, and you’re willing to put in the effort, then you’re going to do alright.