The story of how internationally renown, well-oiled jam band, Bilenky Cycle Works, came to be is labyrinthine. Steve Bilenky, who wants it emphasized that he is only a small part of an excellent team, began his industry career at ten hustling bicycle repairs for neighborhood kids out of his family’s garage. That led to job at the local Schwinn shop assembling and repairing bikes, where he pored over catalogs and absorbed every bike thing he could. Steve was modifying old cruisers and blasting around in the woods with his friends in the 70’s before mountain bikes were a glimmer in the proverbial eye.

His academic and professional direction initially would take him away from bicycles, and his deep-seeded entrepreneurship would draw him into all sorts of unusual ventures. Inevitably, he would return to Philadelphia and bicycles where he went from repair and frame alteration to starting his first bike brand, Sterling Cycle Company – all on his way to Bilenky Cycle Works…

STEVE: Okay. So I was fixing other kids’ bikes and charging them money when I was like ten. See, when I was ten, most of the kids couldn’t leave the block, but I was allowed to cross the street to the shopping center, so I’d go to the penny candy store, buy the candy there, bring it to the garage. I’d have candy, comic books, and bike repair- the original bike cafe.

BIKERUMOR: Wow, so you had this magic ability to cross the street AND go to the candy store.

STEVE: So I’d used my permissive mother. That allowed me to start doing my mechanical entrepreneurship so, you know, pre-building bikes. We used to have these races up and down the driveway, and apparently even at that age, somehow certain bikes were faster. Jeffery’s bike is just like the fastest thing. What made that faster? Putting them inside the garage, putting them upside down, and kinda trying to get inside of them and figure things out. I would do stuff like that, put chains back on, fix flat tires.

I got my own 3-speed. It was a Columbia so it was a welded frame – it wasn’t like [my cousin’s] English racer, a lugged frame. But whatever it was, it was 15-20 dollars, it was all I could afford. But it had a Sturmey Archer hub – that was like the main hub. I had an English hub. The thing is, it had a wheel – most English racers had 26 1-⅜”, this thing had a tire size 26” 1.375. “That’s the same as 1-⅜.” That was the introduction to anachronisms of the bicycle world because 26” 1.375 was actually a different ETRO number, I didn’t know that existed. The tires you could get at the Schwinn store didn’t fit the rim. Do you have a tire? No, special order. Oh crap. Anyway, so it’s like, well, you know, you could just get a different rim and make it like regular sized, like a regular English racer. So I bought the rim from the Schwinn store and, oh, I gotta get this thing on here. I went back once or twice and low and behold, I built my first wheel. I was around 11, maybe 12.

BIKERUMOR: That’s awesome!

STEVE: I was like wow, I got the wheel, I did it in the fork because I saw the guy in the back in the bike store had an old Schwinn flat steel fork. He’d put that in his vice, throw the wheel in there, and he’d true it using his finger.

I came back. I got my wheel, this and that, the spokes poked out a little bit because the rim was a little smaller and I used the same spokes. I was like “I built the wheel.” He was pretty impressed. So my mom went there and talked to him, basically she got me the first job interview, through this wheel I got a job at this Schwinn store.

BIKERUMOR: Cool!

STEVE: The era being what it was, and my thing was, “Okay, now you’re going to assemble bikes.” I would go in the basement. The basement was the showroom, bikes were up on little pallets. I would go down there and build, okay, Schwinn Krates. And those suckers weighed 50 pounds! And I weighed only like, 60 pounds. And I had to carry them up the stairs when I was done. They were all fiddly. Here I am working in a bike store, it was like the dream come true.

Steve would continue to work for that shop up until college. Building Krates turned into cruisers which turned into ten-speeds. All the while he was mixing it up at the New York Bike Show and experimenting with touring. But his relationships with the bikes in his life were riddled with frustrations. Nothing was ever custom or English enough or “Campy” enough for his personal taste. They weren’t quite there. And, when the bike of his dreams would manifest, it would rarely be available in a size appropriate for his 5’4″ frame.

STEVE: So I go to college and I get a job in the bike store there, of course. And I’m taking college girls around to buy bikes and learn about bikes and just being crazy about bikes. I’m in this bike shop working. See, our shop was Schwinn, the secondary brand was, like, Rollfast – they were like low end. There was this guy. His name was Harland. Most of the guys working in bike shops were like me. They were like 18, 20 years old. And this guy was like 42. And he had a beard, but it was perfectly trimmed and organized. Not like today – not like a hipster. He was meticulous and knew everything and drove a Porsche. Harland was like the guy you went to – anything you wanted to know. You just listened and watched while he did magic. I learned a lot there.

BIKERUMOR: Probably gave you hope for playing with toys professionally for the long term.

STEVE: Yeah! He had, like, a wife! He was like a real person and he worked in a bike shop. It was kind of crazy, you know?

BIKERUMOR: And, like, a house!

STEVE: And a car! Who has cars?

BIKERUMOR: And he trimmed his beard!

STEVE: You know and he talked, he was very articulate. Bikes were like part of the esoteric lore of, like, the well-heeled. It was like, wow, bikes are sophisticated! Bikes are all these things! I’m working there. In that shop on the shelf was a Hill Cycle from that shop in Philly. Hill Cycle was a floor bike. It just sat there and stared at me. And I stared at it. This one was a silver and blue. I just loved it – had everything perfect but it wasn’t my size. But it was there.

Love the one you’re with. So that was kind of my story. Bikes that don’t fit. Bikes that weren’t all Campy. Bikes that were slightly not quite there.

In college, I was in Agriculture Engineering and one of the courses… this is really leading up to the thing – you’ll see. It’s all starting to make sense.

BIKERUMOR: I feel like I’m watching a rose bloom…

STEVE: They had a course called Farm Shop Practices. So three days a week, maybe five days, it was four periods long. So half my day was shop. They had this German guy who was like, who was extremely, extremely anal and everything had to be perfect and he drew up this thing about perfection in craftsmanship and how important it was. I was starting to get this new awakening and connecting this to bikes. They had wood and they had a machine shop and they had sheet metal and they had welding and they had brazing and they had painting. These guys from farms, you know I turn around and this guy made this giant haywagon right there in the shop. You had to make a project. It was like, oh, machine shop… a lathe! I’d never used a lathe.

Well, now I can make this bolt thing because the Campy derailleur that I had on my Hill Cycle, low and behold, even though I got the Campy bike with everything Campy, they had already switched to this nylon bushing to take up the slop on the derailleur on the dropout. And it was like, huh, well that’s kinda cheesy. It still had slop. I put the bolt in the lathe and took the back of the bolt down just enough so the derailleur could be swung back to get the wheel out but didn’t have any play any more. This thing of tolerances and machining and then having brazing. So you know, I learned all these hands-on skills and I graduated with this agriculture degree.

BIKERUMOR: That you use every day now…

STEVE: Well, that was the thing. I graduated and I was like “I got a degree and I’ll go to the midwest and I’m going to get a job. I’m going to go to Ramsey, Michigan with this ag company. That’s where agriculture is.” I got me a suit and I go there, and every one of these places- I walk in and the guy interviewing me is like, you know, large and in charge. It’s like, I’m this little guy with a Philly accent, you know, that weighs like a hundred pounds.

BIKERUMOR: You don’t really translate to the midwest.

STEVE: In college in agriculture engineering, my advisor in agriculture engineering was like “there’s this national science foundation thing. If you write this thing and you make a proposal, you could get money to run this project. In that shop in agriculture, I didn’t make a hay wagon. I made a methane generator. I got cow manure coming out of my wazoo here in the next building, and I got this big tank and I welded it, brazed bolts on, and converted this large metal tank into this methane digester where you just put cow manure. This thing’s guzzling out gas. Like, hey, you can power your tractor with this! So then, every professor was like, they either came from the midwest or they were old head farmer guys from Pennsylvania mountains or whatever, and I was just this weird little guy from Philadelphia with the accent. “You don’t know nothing about farming, sonny.”

BIKERUMOR: I can only imagine. I remember the Ag Engineer kids in school – totally different breed.

STEVE: So I’m going to these interviews and I’m starting to get the picture. “I don’t think I’m going to fit in the ag business world in the Midwest because people can’t even see me.”

So my world kind of fell apart out there. Basically, I’m out there in the midwest with no job and living with my friend. I took some other vo-tech school stuff out there because I was really into, like, if you’re going to have an intentional community and a farm, you need to learn how to lay bricks, so I took some more classes while I tried to figure out what I was trying to do.

BIKERUMOR: I like how all this stuff is going on, all these little tangents.

STEVE: Yeah. I took a job, this was in Grand Rapids Michigan, it was this old German couple. “We’ve been baking this stuff here for 40 years. It starts at 3 in the morning.” I’m shaping rolls by hand. I’m making donuts. That was kind of fun. Looking in the paper and it’s like, “Oh, exotic dancers. I could do that.”

BIKERUMOR: No way!

STEVE: One of the other things I did in college, since I had extra credits, I took modern dance when I was at Penn State. “I’ve gotta do it. I’ve gotta make some real money. This is how you do it.” They had these ladies nights. It was this roadhouse thing. It was like, “Okay, here you go.”

At some point, I had to come to grips with like, well, am I going to stay in Michigan with these people who talk funny and big women? I gotta go back to Philadelphia.

So I kinda packed it up and went back to Philly and went back to the old job at that bike store because it was all I knew. And of course my friends were like, let’s go, we’re going to start this other band. All this crazy rock and punk is starting. Started a band. I had a bike repair shop where I didn’t sell any bikes, I just had this basement bike repair place and all I did was like – it was called The Bike Doctor and my focus was “I’m just going to rehab. No bike left behind.” All the other bike stores, they would never fix it but I will. Of course, that led to “I got this bike and the frame’s bent.” Oh yeah, we used to bend frames at the other shop. Okay, no problem. “Oh, this thing broke off and it needs to be brazed.” So I got tanks and started brazing things on bikes. So basically, that led into frame repair and I started modifying.

So yeah. Basically left exotic dancing behind. Got into the torch.

BIKERUMOR: You went from being the torch to using the torch.

STEVE: That’ll be the movie byline.

BIKERUMOR: “Torch to Torch: the Steve Bilenky Story”

STEVE: I still have a picture or poster I had someone do, like, oh, you know, Bilenky Cycleworks: still carrying a torch for you.

BIKERUMOR: That’s amazing! So you went through this journey where you’re just gathering up all these random skills, and then you basically hit the point where you have to move back to Philadelphia.

STEVE: Basically I knew three things. I knew gardening and farming. Without the money to get land, it wasn’t going to happen. Oh, and I knew music – used to have a band.

So I figured bikes out of the three – that’s the most commercial. People would pay for that. I did the band on the side and the bikes for money. I moved into a house with other guys from the band and lived that life. I had this shop. I wound up getting married – which was totally abstract and not what I expected or what I wanted to do because also she wanted to have children. I had no concept or idea that I wanted to have children.

BIKERUMOR: You got a couple of them.

STEVE: I got four of ‘em. So then my bike shop’s getting bigger. I have one child and a bike shop and I lived in the back of the bike shop for awhile. I told you about bending bikes, fixing bikes, brazing bikes. I’m like, hey, this Stumpjumper thing is kind of cool and mountain bikes. Took a Stumpjumper as soon as they came out; I had one of the first in Philly. I was trying to be forward.

There were, you know, “Mountain bikes are like – they are ten speeds. They are the best commuting bike!”

I was like, huh, commuting bikes… I’ve commuted plenty. These things are just too heavy. These tires are knobby and the geometry’s not quite it, and they are so heavy! And they don’t have a chain guard or a kickstand or lights. This is not a commuting bike.

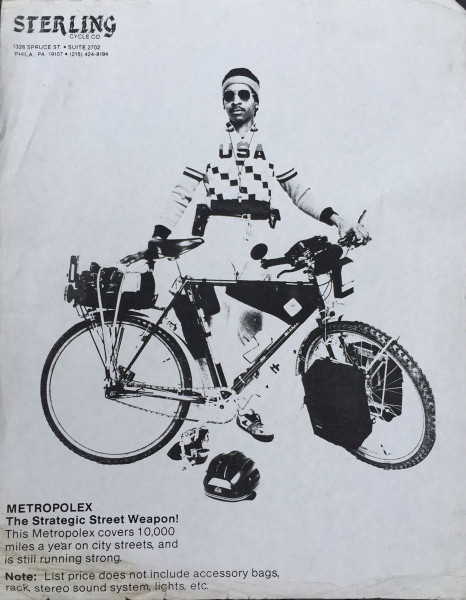

So I started taking Japanese frames, old Miyatas or whatever, and “Okay, I’m going to redo the braze-ons, change the spacing, put on things for racks and fenders.” I did light weight 700c alloy rims on alloy 5-speed internal hubs by Sturmey Archer. So I made this bike, and it’s like, I’m going to make this bike company. Basically, I’ve had this suppressed mechanical entrepreneur thing from when I was kid.

I’ve done different businesses all the way around. I had a landscape business and fixing businesses and food, I used to sell philly soft pretzels. You do things and you make money, not jobs. I only had one job I think in my whole life and it was that bike shop.

used with permission from Steve Bilenky

So I make this bike and I say, well, I’m going to make this bike company. Company’s going to be called Sterling Bicycle company because it’s kind of English sounding and I don’t really want to be, you know, like a frame builder. I want to be a bike company. Trek turned into a bike company, so maybe I could be a bike company. So it’s like why not? If Trek can do it, I can do it. So I made this bike called the Metro Five it was the ultimate commuter bike. $595.

BIKERUMOR: Where you personally building them?

STEVE: The first couple prototypes were adapted bikes to like, figure this out. I said, “everybody really likes this.” Not everybody, but people are like “that’s a really cool bike.” Great riding and this whole thing. Basically taking a nice quality lugged frame and putting it upright, everything alloy, really nice 5-speed hub, instead of a tank Raleigh Sport 3, it was the Metro Five, for the US market that wants quality and was used to, “I had a racing bike when I was in my teens and twenties and now I’m a college professor and I want a good quality commuting bike.” I found this little niche. Mountain bikes were this cool thing, but not really good commuting bikes.

One of my old connections from New York Bike Show, because I would go there every year, where I saw Bruce Gordon, and I was like bowing down to Bob Jackson right there in New York. I was putting ads in the back of Bicycling Magazine, having bikes made by one of the guys I met at New York Bike Show in Birmingham, England. And he worked for a company called Crown Cycle. I’d call them, we’d talk about bikes. I would order these bikes over the phone and send them letters and say I want this this this this geometry. “No problem, no problem.” Price was right. They would come in a box of six of em in the mail. It was kind of crazy. And Bicycling said “Oh, we want to do a review of your bikes!” So they put me in there with a Trek mountain bike, an 850-something, and four other mountain bikes and my bike. And I got a really great review with pictures. Best commuting bike and blah blah blah. It’s 1984 and suddenly people are calling from all over the place.

BIKERUMOR: And you’re like: shit! Infrastructure problem!

STEVE: Yeah. It’s like good, this is good, this is what I want! Oh, but the frames are shit. One of the frames I gave to one of the editors… they had this thing at Bicycling called the Tarantula. It was a frame testing thing that tested stiffness. He said “by the way, we put your bike on the Tarantula. We did all these things… we were testing the bike, it actually bent.” They didn’t put it in the review or anything. We were having problems like the guy would put the braze-ons on wrong.

I was started to get custom orders from women. I was doing bikes with like 600a and 650c wheels. It’s like, I’m selling bikes and it’s like, oh, I’m 5’4” and these are the kinds of bikes you need. But I couldn’t get what I needed.

Well, I got this torch and I got this thing and my friend has a machine shop. So I started going to his machine shop, made like a fork jig and a fork alignment thing, and a frame alignment thing. He signed on a loan and I bought a paint booth and Hydra frame jig from Bike Machinery in Italy, like Richard Sachs has. This mechanic that worked for me was this crazy artist. He became the painter. Sometimes in my stories, it’s like, well, there’s no internet. You could either see things live, read it in a book, or call people on the phone. So this guy Dave Moulton was one of my mentors and he was selling his bikes in the shop and we would talk on the phone and I would ask him stuff.

We’re building bikes and showing bikes at the Long Beach Bike Show, maybe Anaheim, and I’m doing tandems because, it was this other thing I was selling in my shop. All this stuff going on. Had the Metro 5 there. Second morning of the show there’s a little business card sticking out of the Metro 5. “Joe Breeze Bicycles.” It was a little handwritten note that said “Nice bike.” So that was sort of, aside from Bicycling, kind of bringing it to the world. Here was this guy that I knew was like a big deal, and it was a big deal to get that thing. I don’t know, that’s my commercial start. I was trying to be a bike businessman and a bike frame builder simultaneously with no internet and no classes or anything like that.

BIKERUMOR: Did you have Sterling and Bilenky at that time?

STEVE: It was Sterling Cycle Company.

BIKERUMOR: So Bilenky didn’t exist.

STEVE: Bilenky did not exist other than my name was Bilenky.

BIKERUMOR: When did Bilenky happen? How long did Sterling last?

STEVE: At different times I’ve thought about bringing it back as a different brand for production bikes. Like, I want to do a production touring bikes again. I want to do a production tandem. That was another thing. I did a club touring bike, a loaded touring bike. I would do it in different wheel sizes. 26″ or 650c for women, or 600a for really little women. The business now is, obviously, things have kind of exploded again. Like another mountain bike revolution.

Because when I started, mountain bikes were just starting. I even built some bikes for Fisher, because he was looking for people to do fillet brazed bikes. Before it went totally Taiwan and Asia. So the whole explosion of mountain bikes was – they were making new parts and tubing and ideas. That was kind of driving the businesses of people, because mountain bikes were changing every six months. Little builders could keep up. At that point, builders were almost dropping off to almost nothing here. But the mountain bike is what made American Framebuilding come back again. Fat City, I was selling Fat City.

I just kind of became part of that world of American made bikes again. I guess I had somewhat of a business and did this expansion and moved into the space I’m in now in 1992. Part of it was, I’ll say advisors and silent investors, like, “forget about this Sterling. You need to use your name Bilenky. That’s what people really want to buy.” I was really reluctant. Partly, I was like I don’t want to be the thing where I’m the guy and I’m the big deal. I wanted to keep it non-personal so it could be a bigger company like Trek.

BIKERUMOR: That’s funny, that’s not a typical frame builder approach.

STEVE: Right.

BIKERUMOR: I don’t want this to be about me or too personal…

STEVE: Right! It’s really not supposed to be about me. In 1992 it was called Bilenky, and all of a sudden it became- even though I had more people working for me, it was still Bilenky. I just became Bilenky and Bilenky became its own thing.

We’ve gone with the different trends when we were doing a lot of tandems and Bicycling wanted to do another review in 1994. I said “oh great! I can get some of my tandems in a magazine and that will really start pushing sales. I had really geared up, I’d borrowed more money – I really tooled up to make tandems. For awhile, I was the third biggest tandem maker in the United States.

I did tandems in the mid 80’s. There was no CoMotion. They started in ‘88. I’d already been doing some. They were on my heels. And then of course there was Burley, they came on a little later. And then there was an article on the Wall Street Journal, like Tandems are going to be the next big thing. So I put more money into tooling, focusing on tandems and buying parts, doing stock tandems that we could sell to dealers. It was like, eh, it wasn’t really doing. And then Burley came on with their cheaper tandem. And CoMotion had their tandems. People liked the fillet brazed tandem. We were looking for ways to make it cheaper with low finishing… I wasn’t really a welder.

I went to this one show and Ibis was there and he said, “Well, I’ll tell you, the only way to make bikes is they’ve got to be welded. That’s the only way you’ll make money.” I just had this really sinking feeling. Welded bikes? “Yeah, we did this, but that’s the thing… if you want to do production, you have to do welded.” I had no interest. I hated welding and I hated the darkness and noise. I was just a brazer, so anything finely crafted was brazed. Welds were for BMX bikes at best. Of course, with mountain bikes, that all changed. With mountain bikes, welding became the pinnacle of things and I wasn’t doing that.

I was trying to do these Tandems and Bicycling said “we want to do an article on five frame builders.” Interesting, one of the frame builders was Bontrager, the other one was Weigel, another was Bob Jackson who was “Oh, my hero!” And I’m trying to think of the other one. But there were five frame builders. “What kind of bike?” I said, “A tandem!” And they said, “No, we want a custom touring bike.” “I used to do touring bikes in the 80’s. I’m not really into touring bikes.”

I’m trying to make money on tandems because I really don’t want to compete in the realm of single frame builders. At least tandems, well, at least there are only two wheels and one fork – hardly anybody makes them. I was kind of competitive and doing business. It was like, I really want to put a tandem in the Bicycling article. “No, we want you to make a touring bike. Each editor is going to have a different bike made from a different builder.”

BIKERUMOR: That sounds like a scam!

STEVE: Right!

BIKERUMOR: “Hey guys! Let’s all get custom bikes! Who do you want?”

STEVE: We got this really great review on the Midlands touring bike. And, you know, it had racks we made. We were making these fully integrated bikes, kind of like that Jack Taylor thing but slightly more modern. With an oval top tube and fillet brazed, racks, and fenders and we even had this under bottom bracket dynamo from Union with this capacitor thing on the seat tube- when you stopped, the light would stay on. All that stuff. This editor loved it. All of a sudden, I was supposed to be a tandem bike company and people were trying to buy single bikes.

I can’t make money on single bikes. There’s more money for tandems. People pay more money for them. There’s people who want to buy single bikes. So lo and behold I’m making single bikes. The business changed again. Selling touring bikes. Once again, custom bikes for women. And that was a big part of what I did.

In 1994, I go to CABDA. Some company, they were in Phoenix, they were an American industrial company. They made helicopter blades or something. And they were going to make carbon fiber parts. It was like “shit I really need to do a carbon fiber tandem.” I’m like “I gotta figure out this carbon fiber thing. It’ll be great. It’ll be light.” I was talking to this company. They were interested in doing private label stuff. But I couldn’t put that together because it was big money.

The other thing was this big tall guy, was actually from California. He had these machines on a table. “what’s going on here?” “These are S&S couplers. With these, you can make your bike into a travel bike.” They were only available to frame builders. You had to have insurance.

BIKERUMOR: Minds exploded.

STEVE: Yeah! So it clicked. Like, single bikes are cool. But I know one thing. People buy my tandems and go places. I need a tandem that gets small. I did the first S&S coupler tandem. It was the 1994 Christmas Buyers guide. 25 of the coolest things. The first thing was a tinker tandem, a red white and blue tandem. Everyone’s mind in the tandem world was like boom.

So it’s like, beside the tandems, we were doing touring bikes with couplers, club touring bikes with couplers. There was a magazine, Tandem magazine that was pushing the envelope. There was also AerMet 100 that was this really high end tubing people were trying to make mountain bikes out of. It’s the parent material that they make 953 out of.

That was something from a show in ‘94. It was like, AerMet 100 tandems with Couplers! We had a 33 pound tandem in Tandem magazine, steel tandem with White Industry hubs with titanium spokes with the lightest stuff. We were kind of hitting on all this crazy high tech stuff. We did the first tandem that could become a triple!.

BIKERUMOR: What!? You would just pop in the middle?

STEVE: Yeah. And we had a tandem that could become a single. “Well, I’m going to go touring with my wife but she doesn’t want to go as far.” It was a regular touring bike but you took the ass end off and it became a regular bike.

So basically, we were doing all this crazy stuff in the 90’s, and travel bikes were becoming big. Putting couplers in other people’s bikes – that became a thing we were known for. Because no one else seemed to want to do it. Well, we can do this, it’s no big deal. Once in awhile, we would run into to something. Then we did titanium ones. Then that led to making titanium bikes. Then 9-11 came and no one wanted to go on an airplane, so suddenly bikes with couplers weren’t a big thing.

BIKERUMOR: I didn’t even put that together that that would be a thing. Wow.

STEVE: 9-11 is when things went south as far as the business. Had to build it back up. But then Couplers came back. It all came back. Lo and behold, I couldn’t tell you the moment in 2003 or 2004, but there was this spark of hand built steel bikes. Because all through the 90’s, you know what was happening with single bikes. They were all moving to Aluminum, then Titanium, then back to Aluminum…

BIKERUMOR: And everyone talking about how steel was going to die any second. People were jumping off the ship like crazy.

STEVE: You either moved into carbon fiber, or you were really niche and lucky had this tandem thing and the couplers because other than that, people didn’t really want steel bikes. But somehow there was this little germ and, I don’t know, “Made in the USA.” “Handcrafted.” “Small scale production.” “Buy local.” “Lugged steel.” Rivendell was doing it. Touring bikes again.

BIKERUMOR: So you’ve been at this for awhile. Are you still stoked? Is still fun?

STEVE: Yeah! It’s a hard business. There’s a lot going on and stuff that – you know, gets you downtrodden. But putting stuff together and tinkering in your garage. I have a few little things that I shouldn’t be thinking about but… I’m so excited about this cargo bike thing I want to do. It’s ridiculous. I look at myself and go “you just have to do this and make money because this is what you do to make money. There’s this thing and it’s like, oh, as many times as you do it, like, “We can do this and it will only take this long.” Nah, it’ll take a gazillion hours and like, you’re not going to make any money for it. But oh, my mind is now captivated by this thing that I want to attempt to do. I don’t even want to do it at all. There’s always that next thing, I don’t want to make eTap, but there’s a thing I want to do, somehow that keeps you alive and going. You want to create something. It is a realm for creators. They have a place, they make bikes, they make a lot of bikes. They may make more money. But it’s like, on one hand, I’d like to make a lot of this or that, I don’t know if I want to structure my life to be that.

I wouldn’t have wanted to live like that. I’m still captivated by doing crazy shit.

BIKERUMOR: Being Steve Bilenky seems like a cool thing to be. What do you tell someone who wants to be you?

STEVE: All the stories is what makes it cool. Everyone has their own story. I guess it’s that thing of like, well, it would be like someone saying “I want to be a blues guitarist.” There are people who can play it or sound like it. But you really gotta wanna do it. Because you’re going to have to go do it for the sake of doing it, and you’re going to have to do it long enough because as much as you think that oh, you’re going to figure it out, no. You really just gotta want to do it for its own sake. Do it long enough and you’ll get known.