After getting the scoop on Rotor’s new 1×13 hydraulic shifting single chainring 13-speed road, gravel & trail bike groupset last summer, we knew it was going to be unique. What we didn’t realize, was that with no wires to route no batteries to charge, it was going to offer one of the lightest possible complete road bike groupsets at just 1785g. That will make it easy to build up a complete disc brake road bike under the UCI’s 6.8kg weight limit when it is available in just over a month. And you can probably do the same for cyclocross or gravel too…

Rotor 1×13 single chainring, 13-speed hydraulic drivetrain

If you haven’t ridden a Rotor road / dropbar groupset, there are few key things to be reminded of. One, Rotor uses a closed hydraulic shifting design with mineral oil that is substantially lighter than either traditional housing & shift cables or any wired or wireless electronic setup with its batteries – no cable adjustment, no charging. Another point is that Rotor makes everything in-house in Madrid, Spain. That means Rotor leans a lot on what they do best, precision machined aluminum & steel.

Why 1x road, and why 13-speeds?

So why 13-speeds (instead of the 12 of Campagnolo or now SRAM AXS)? Rotor thinks that adoption of 1x systems will revolutionize road bikes just like it has for mountain bikes. 1x is more simple, more aero, more reliable, and just lighter with fewer components. The biggest obstacles to real road 1x adoption beyond cyclocross and adventure gravel has really just been available gear ratios and consistent cadence.

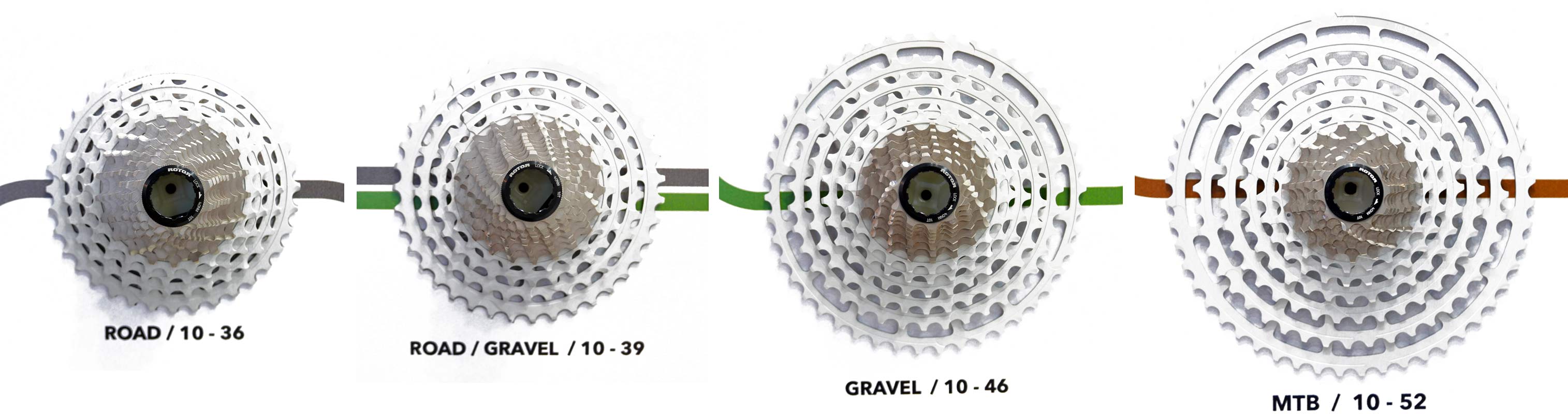

So Rotor developed 1×13, taking a wealth of pro & amateur rider power meter data into consideration to evaluate optimal cadence & gear ratios for a wide range of disciplines. Their thinking was that with a single chainring, 13-speed groupset, Rotor could deliver the best gearing spread & most consistent gearing steps in the industry with four different cassettes (10-36, 10-39, 10-46 & 10-52) and a simplified setup with only a rear derailleur.

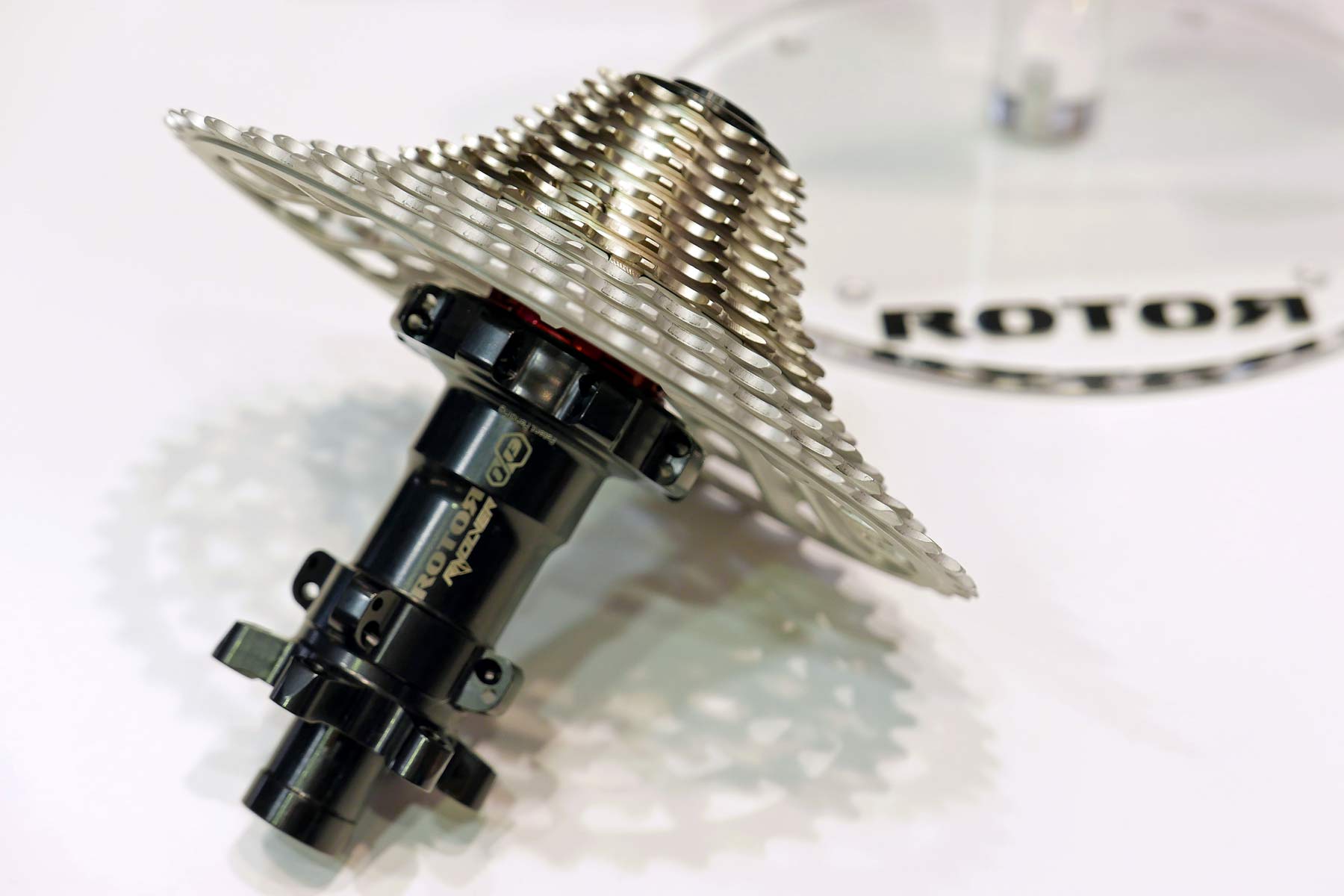

To make it work they needed 13 cogs, so Rotor maintained the 12-speed cog-to-cog spacing (to maintain compatibilities) but just added a 13th cog. For now that means that you need a set of Rotor Rvolver hubs to complete the group. But also as a stopgap, the new group will work with any 12-speed cassette (including Rotor’s versions that use the same ratios minus the 10T) on wheels with current Campagnolo or SRAM 12-speed ready hubs. Then, when the time comes to update/upgrade your wheels you can add on that 13th cog.

Rotor 1×13 groupset pricing, claimed weights & availability

We go into greater detail in a separate article about the component-by-component breakdown of weights & prices. A complete groupset of shift & brake levers, brake calipers & rotors, and the new 13-speed rear derailleur sells for $1830 / 1667€ (cranks, chainring & chain excluded). Add in another $415 / 380-400€ extra for the 13-speed cassette (plus the need for a specific hub) or $365 / 334-350€ for a 12-speed version to work with your existing Shimano freehub wheels.

As to the weight, Rotor’s claim of 1785g complete includes both shift/brake levers, brakes with 160mm rotors, the 1×13 rear derailleur, uncut hydraulic hosing, a 10-36 13s cassette, and an uncut KMC chain. For availability, Rotor says to reserve a group from your local shop or online from them with a 500€ deposit for April 2019 availability.