Schwalbe has today launched the Green Marathon bicycle tire, 70% of which is made from recycled and renewable materials. In this bold move toward a circular economy, the brand claim it is the first bicycle tire that “closes the loop” – the recycled tire itself being recyclable at the end of its usable life. As compared to its predecessor, production of the Green Marathon is said to require 34% less CO2.

In a state-of-the-art pyrolysis process that takes place in Germany, Schwalbe is taking discarded tires – be they bicycle or automotive – and breaking them down into their constituent components ready to be reformed into new Green Marathon tires.

The recovered materials are then shipped to Vietnam and Indonesia where they are used to produce the Green Marathon. Even with this extra step of shipping, the overall carbon footprint is reduced as compared to that of the outgoing Marathon.

The Green Marathon is currently the only Schwalbe tire produced in this way. However, it being the brand’s best-selling tire of all time, it seems a great place to start in reducing impact on the environment.

And, they’re not stopping at the Marathon; Schwalbe plans to roll out this more socially and environmentally responsible approach to tire production to more of its bicycle tires in future. For now, let’s take a closer look at the Green Marathon, and the steps required to produce this first-of-its-kind recycled tire.

Schwalbe Green Marathon

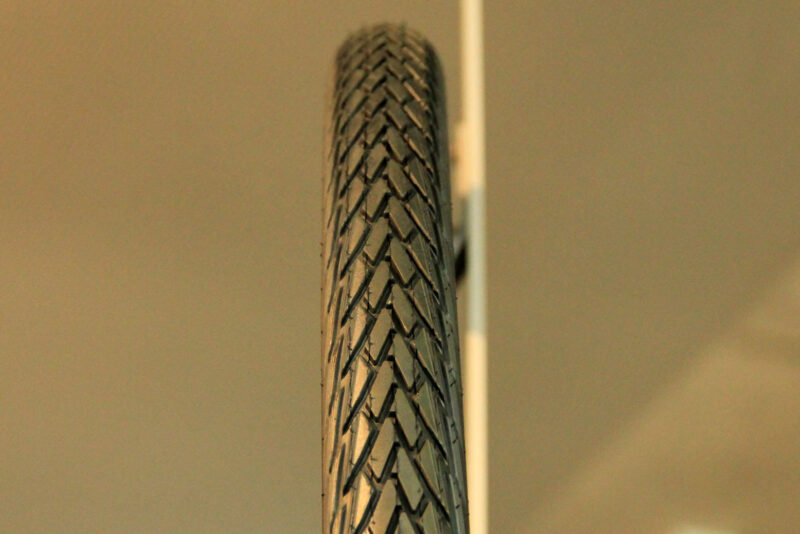

Schwalbe Marathon fans will note that the switch to this greener manufacturing process comes with a significant tread pattern update. While the outgoing Marathon saw a slick center tread cap, the Green Marathon is more textured in this region, offering up more edges to bite into softer terrain. Despite this, we are told the Green Marathon is in fact slightly faster rolling than its predecessor.

The Schwalbe Green Marathon is intended for a wide variety of bicycles, from touring bikes to urban commuters and eBikes. With its launch, new sizes are added to the line-up, including higher volume options that are better suited to eBikes.

So, what is it made of?

Seventy-percent (by weight) of the Schwalbe Green Marathon is produced from recycled and renewable materials. But, what does that really mean?

Let’s break it down.

We first got wind of Schwalbe’s intention to produce a recycled tire back in March, when they announced receipt of a supply of recycled carbon black (rCB) from their recycling partner, Pyrum Innovations AG. Carbon black is used as a pigment and reinforcing phase in tire manufacturing, but its manufacture is environmentally damaging – it comes from the incomplete combustion of coal and coal tar. So, isolating this essential component from old tires is preferable, from an environmental standpoint, to continuing its production from fossil fuels.

The Green Marathon’s new Addix ECO rubber compound is the first production tire from Schwalbe to contain the rCB from Pyrum Innovations AG – 100% of its carbon black is rCB.

The rubber itself consists of a combination of natural virgin rubber, as well as recycled rubber, while the silica – an important filler necessary for grip in wet conditions – comes from rice husk ash. That latter aspect does not compete with food production. We are told the rubber is 98% pollutant-free – what that 2% is, we are yet to learn.

One third of the Green Marathon’s puncture protection belt, GreenGuard, is made from recycled latex products, while the the other two thirds are Fair Rubber. Finally, the bead core wire is made of recycled steel.

Despite use of such a large proportion of non-virgin rubber, the Schwalbe Green Marathon is said to be equal in performance and durability to the not-so-green Marathon that it replaces.

“The Green Marathon combines innovation and environmental friendliness on a new level. It is the result of years of research work that we have carried out together with our production partner Hung-A. We at Schwalbe are immensely proud to be able to present a model on the 40th anniversary of the popular Marathon that represents a milestone in terms of ecological responsibility. And most importantly, the Green Marathon doesn’t compromise on performance in any way and continues to lead the way in puncture protection and mileage”.

Frank Bohle, CEO of Ralf Bohle GmbH, the company behind Schwalbe

What about the remaining 30%?

The remaining 30% of the Schwalbe Green Marathon tire is virgin material, i.e. new rubber that does not come from a recycled source. To source this in a socially responsible manner, Schwalbe work with fairrubber.org, an organization that ensures the South East Asian communities working to harvest the raw material – latex – from the rubber trees, get more money for their work.

Money that comes from Schwalbe – an extra 0.50 € per kilo of natural rubber – is paid to the farming communities responsible for harvesting the raw material from rubber trees at the very beginning of the supply chain. The money doesn’t go directly into the pockets of individuals – rather, it goes to community cooperatives that appropriate the funds as they see fit – the building of new schools, for example.

“Taking responsibility is a natural part of our business. We are a family-owned company. We are operating within the cycling industry and, as most of us know, the bicycle promotes an efficient, healthy and emission-free mobility. So, we think it is our job, our duty, to make the bicycle as socially and environmentally responsible as possible. Some of these initiatives include the well-being of our employees and their families, the higher fair working standards in our supply chain. And of course, part of the reason why we are here today; products that are circular and as eco-friendly as possible”.

Felix, head of the Corporate Social Responsibility Team at Schwalbe

Clearly, there is a huge amount of information to be unpacked here, particularly around the details of the recycling process and the logistics of production. Overall, this appears to be a good step in the right direction toward more sustainable tire production, and we hope other tire brands and manufacturers will take note.

As we head into EuroBike week, time is short. We hope to bring you a more detailed explanation of the process, with a background to Schwalbe’s decision-making around this new eco-friendly approach, in due course. For now, we leave you with a quick Q&A session that was held following the press conference.

Bikerumor: Can the Schwalbe Green Marathon be recycled at the end of its life?

Schwalbe: Yes.

Bikerumor: What is the limit in terms of the quality of the rubber that you can produce from the recycling process, in terms of performance?

Schwalbe: Honestly speaking, the limit right now is unknown. We are in the middle of research and development, and what we are presenting today is a tire that lasts just as long as the old Marathon, which is known to last for thousands and thousands of kilometers. In the background we are also testing tires for other segments as well. Hopefully we will be able to show you more in the future.

Bikerumor: How are you controlling the consistency of the final product, when there must be such a large variation in the batches of recycled tires that you receive to begin the process?

Schwalbe: That is the great challenge when you use recycled materials. With virgin materials, you have one input and one consistent output. With recycled materials, we have many different varying inputs, which can lead to different outputs. So, we have quality controls on our side. We have to say, our recycling partner, Pyrum Innovations, have done a lot of investment and development in showing that we have one continuous constant output, so that we don’t have any changes in quality in our output.

Bikerumor: Is there much waste along the way? Do you have to discard a certain proportion of the tires you are given to recycle because they don’t meet a certain quality, or does everything go in?

Schwalbe: Some tires – like some spike tires, we currently can’t recycle. But this is also something that we are working on right now so that all tires can be recycled.

Bikerumor: Is the final rubber compound slightly different in its properties to the compound on the outgoing Schwalbe Marathon?

Schwalbe: It is nearly the same. There is a slight difference in rolling resistance, but it is only slightly better. The durability is the same. So we tested – this is quite interesting – more than any other product we have launched yet. We tested it in practice of course, we tested it in our laboratory too.

We also made so-called segment tires, where we had the tread pattern of the Green Marathon tire, with the compound of the old Marathon on one half and the compound of the Green Marathon on the other half. Then we tested it on daily commuters for 40,000-50,000 kilometers – then we analysed the tire. So we can say performance wise, and the durability of the tires, is quite the same as the old one.

Pricing & Availability

Price of the Green Marathon tire is equivalent to that of the outgoing model; there is no financial penatly associated with the switch to a more environmentally conscious manufacturing method – at least not one that is passed onto the consumer.

- EUR: 30,90 €

- UK: £30.99 GBP

- US: $32.00 USD