Seven Cycles has been building some of the world’s best-looking and best-riding titanium bikes at their Watertown, MA factory since 1997. While there is no substitute for a bike built 100% to a rider’s exact fit and specification needs, the full-custom ordering process and lead time can deter some potential customers who are after an artisan-crafted metal bike.

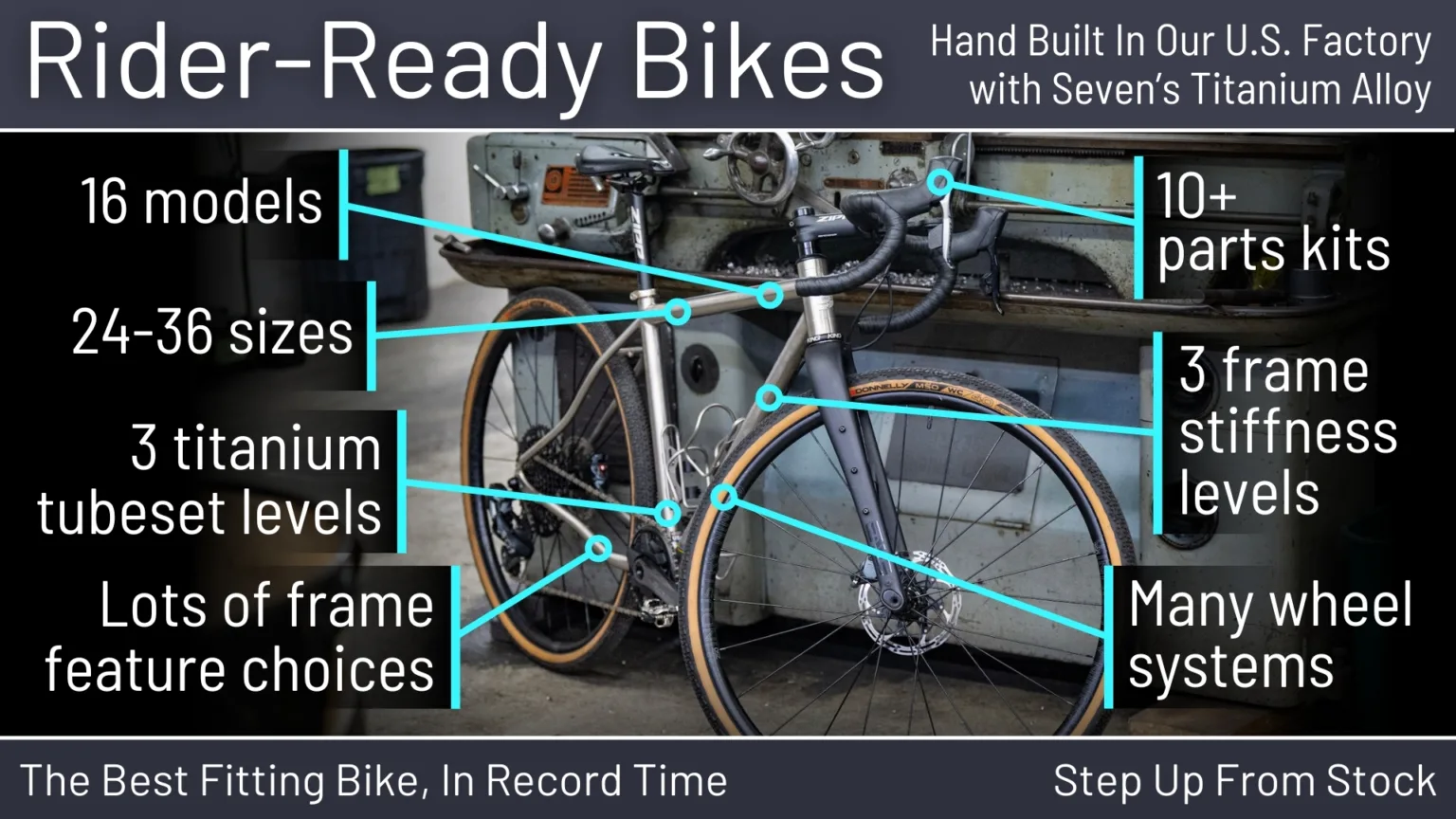

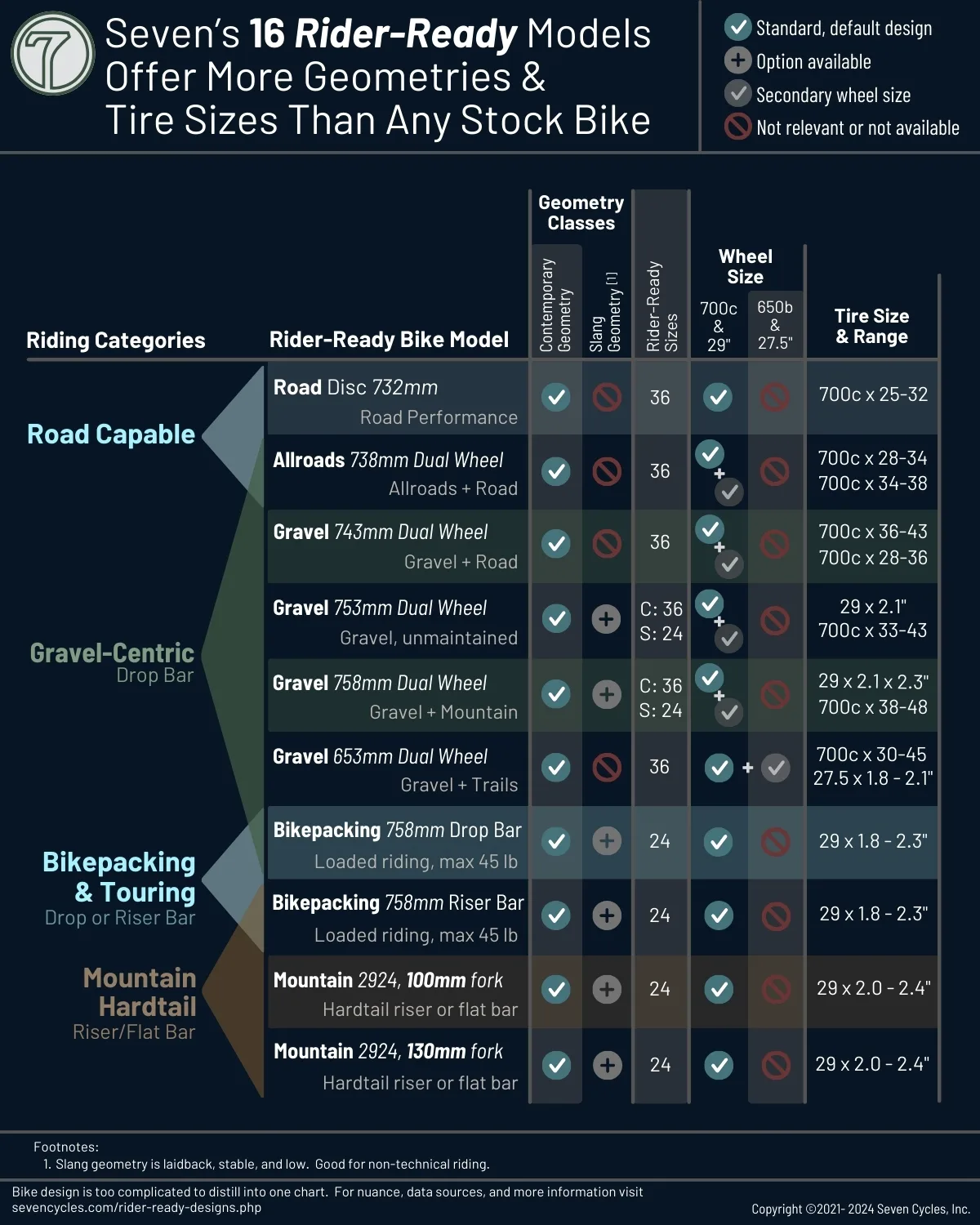

To help this customer get the Seven of their dreams more easily and quickly, the company has launched a new manufacturing system called Rider-Ready that offers 16 models in at least 24 distinct sizes. These framesets start at $2995 and complete bikes at $5,995, and can be delivered in 3-5 weeks. Categories include Road & Allroad, 700c and 650b Gravel, Mountain Hardtail, and Bikepacking.

Seven isn’t the only high-end custom bike builder to switch to this model of ordering. Not only is it more efficient in converting shoppers to riders, but this type of option-based ordering model also cuts down significantly on admin time for the builder, so they can focus on actually building bikes. Of course, for riders whose fit requirements fall outside of the range of what Rider-Ready offers, Seven can still create a full-custom geometry with any other custom options the client needs.

Speaking of fit, maintaining ideal rider fit is one of the Rider-Ready project’s main goals, and to that end, most Rider-Ready Sevens are available in 36 stack and reach combinations, which is 6 times more choices than the typical stock carbon bikes available through the biggest brands.

Perhaps the best way to visualize the size range of Rider-Ready is through stack height. Each of the twelve sizes – determined by top tube length – is available in three stack heights, called Endurance (+3 cm), Standard, and Aero (-3cm). So, if your current bike feels like the correct reach, but you’re way too hunched over, you can choose the same size frame but also select the Endurance stack, thus changing only the one variable that’s giving you trouble.

This isn’t as fine-tuned as a full-custom geometry tailored to the millimeter, but it is a huge step up from buying a stock bike and then trying to make it work with spacers and various stem sizes.

Seven’s Rider-Ready bikes offer all the important customization options. Ride tuning is tailored by selecting one of six grades of titanium tubing as well as two styles of seat stays – “moto” for maximum smoothness and “inline” for classic aesthetics. Bikes are available with UDH dropouts, additional bottle cages, and fender capability, as well as S&S couplers for easy travel. Rider-Ready gravel and mountain hardtail bikes are available with Seven’s “Slang” geometry, which means that the geometry is slacker and longer for better handling on rougher and more challenging terrain.

Each frame is machined, welded, and finished at Seven’s Massachusetts factory. Rider-Ready bikes are available in as many as 14 unique parts kits from Shimano and SRAM, along with upgrades from coveted brands such as Industry Nine, ENVE, Chris King, HED and others.

www.sevencycles.com