When Atomik Carbon launched their fat bike and plus bike wheels, they wanted to build a carbon rim that was strong but still had good ride qualities. Since making a super wide and tall rim can lead to a harsh ride, they investigate other ways of making the rim strong. What they introduced was their first FoamCore rims which utilize a proprietary polyuren foam that is molded directly into the carbon fiber.

More than just aiding in vibration damping, the foam is mechanically stable and helps disperse impacts and load over a larger area of the rim as well as making it stiffer. It’s also hydrophobic so it won’t absorb water, and it’s molded first, then molded into the carbon which helps create a more uniform carbon layup without voids. In terms of non-bike related use, you’ll find the same foam used in applications like helicopter blades and F1 components. Since Atomik is the only rim company to work with their specific factory, they also have some unique advantages in terms of the carbon itself. Wayne mentioned that since the factory makes their own pre-preg carbon fiber (rather than sourcing it from another company), they are able to make adjustments to things like the resin system which allowed Atomik to make the carbon less brittle.

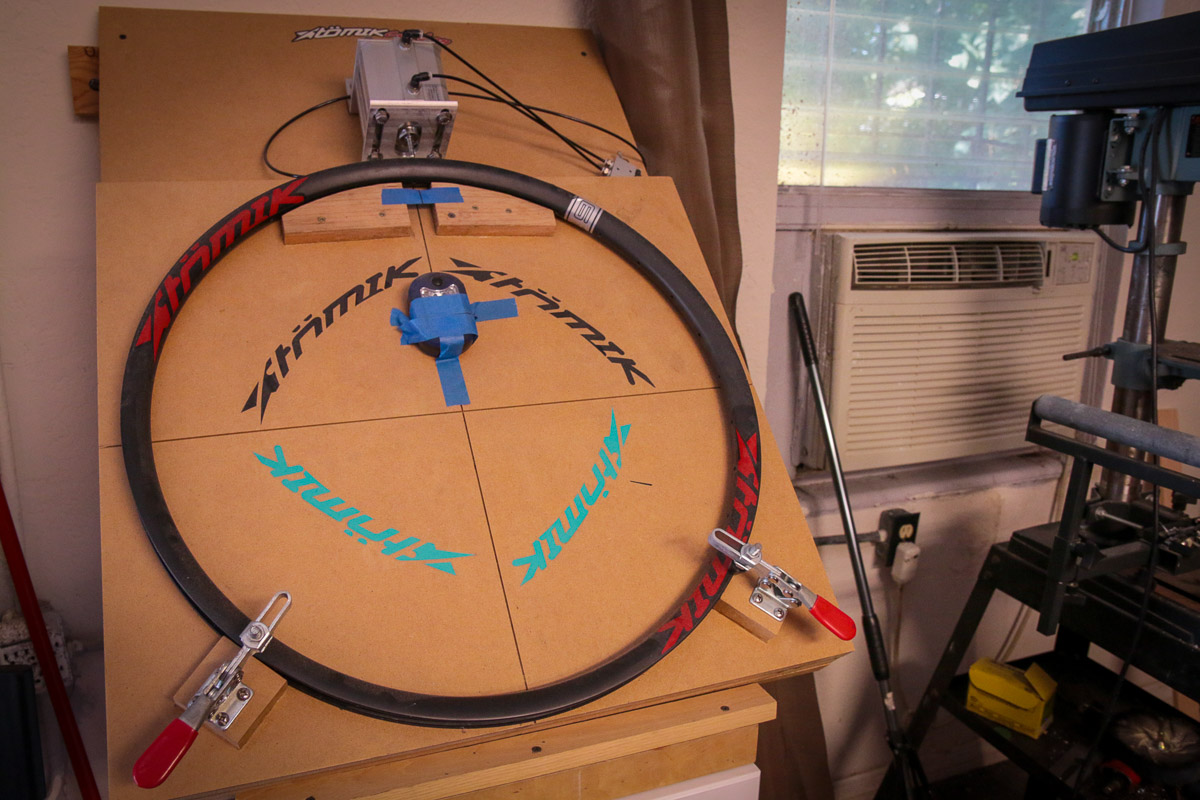

The thin profile of the fat bike and plus bike rims basically necessitated the use of the foam, but now Atomik is looking towards FoamCore for a new category – Downhill. Marking the first use of the FoamCore technology for a traditionally shaped rim, the new DH35 is a 28mm internal, 35mm external hookless carbon rim that is meant for DH and park riding specifically.

Earlier this year, while touring the Atomik headquarters before the Roads Rocks and Reggae event, we noticed a set of unmarked wheels with a special name attached to them. As it would turn out, Atomik CEO Wayne Lee was hand building (like all Atomik wheels) a set of the new DH35 wheels for Thomas Vanderham to put through the ringer. And after six months of testing, he has yet to report a single issue with his test sample. Along with Vanderham, Lance Canfield has been on a set, as well as a number of fast DH racers who have yet to damage a rim. With a number of riders pushing the limits on a DH rim, zero failures is pretty impressive.

When they’re available in about two months, DH35s will be sold as a 27.5 or 29″ rim with claimed weights of 570 or 600g. According to Wayne, the FoamCore adds about 100g to each rim, but he and testers feel like the increased durability and ride quality is worth it.

Expect individual rims to sell for $450, with custom complete wheel builds available. You also get your choice of decal color with the graphics cut and applied in house.