The 2019 Fox mountain bike forks lineup debuted just before Sea Otter, introducing the lightweight Fox 34 Step Cast for racy trail bikes, and an all-new GRIP2 damper that brings high end performance to mid-level forks. Compared to the original GRIP damper, which sits below the FIT4 damper in their hierarchy, the new GRIP2 adds high speed rebound control, more internal oil volume, and refined shim stacks and valving. With the original launch a little light on the tech details for our tastes, we grabbed them at Sea Otter to get the scoop. Here’s how it works:

Starting at the bottom, the new rebound circuit puts the high speed stack on top, using a Leaf Spring (A) on top of an Adjuster Plate (B). Turning the HSR knob on the bottom of the fork rotates the Leaf Spring around, putting more or less of the Adjuster Plate against it…note how the part of the plate directly under the spring curves inward such that as the spring was rotated counterclockwise, there wouldn’t be much of the plate contacting it. This changes how much force the spring puts on the plate, which changes how hard the oil has to press against it to open the port.

Low speed rebound is handled with an internal port and needle-like system that simply opens or closes the flow path.

Built into the rebound circuit is the Mid Valve (C), which is a non-adjustable part of the compression circuit that helps keep the fork sitting higher in its travel and not diving under hard braking. It’s a simple fixed shim that works in conjunction with the high- and low-speed circuits.

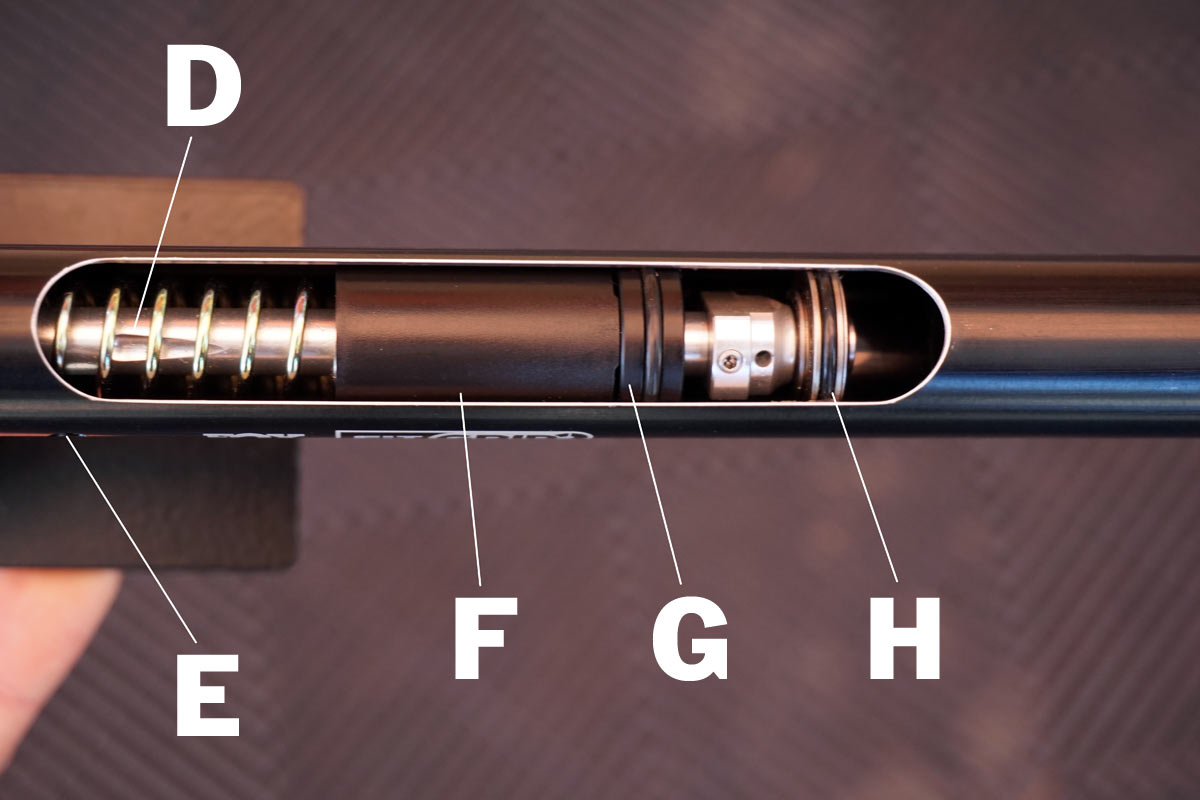

Up top is the compression circuit and IFP. The IFP system sits at the very top and uses a sealed Piston (G) with a coil spring to keep pressure on the oil that sits inside the damping circuit below it. A Cover (F) prevents the spring from abrading the inside of the stanchion.

Above the IFP is a Tear Drop Purge Port (D), which does several things: First, it lets any air that might get into the system burp out. Same with excess oil. Because of this, the system is robust enough to deal with poor bleeds or lackadaisical maintenance. It’s sort of self correcting. It also means that if oil that’s put into the lowers to keep the stanchions sliding smoothly works its way into the damper through the seals on the bottom, the excess can simply purge out of the top. This design lets Fox use a light seal, which reduces friction, so your fork feels smoother. Once oil does purge out of the top, it’ll slosh around and eventually find its way out through a hole (E) in the damper’s cartridge body. From there, gravity will bring it back down to slosh around and lube the stanchions…and the cycle begins all over again.

The compression damping happens inside the Compression Valve (H) which, unfortunately, doesn’t show much externally. There are high speed shims sitting on top, just hard to see in this photo. Inside the shaft is the low speed port, with a needle that dials into it to restrict flow and slow things down. Or vice versa to speed it up.