From the outside, the Specialized headquarters building in Morgan Hill, CA, looks much the way it did when we visited last summer and toured it. And parts of it still are, including the museum, Robert Egger’s concept room (where there’s so much to see we broke it down into parts 1, 2 and 3), and the Win Tunnel. But deep inside the maze-like building, they’ve cleared room to build a massive new R&D section, housing distinct rooms for their testing lab, carbon fiber prototyping, a machine shop, 3D printing, and much more. And for the first time, they opened it up for (almost) no holds barred photography. Here’s what we saw…

To get to the new research area, you have to go through the employee lounge, which sits adjacent to the workshop where test bikes and employees’ rides are wrenched upon. That brings us to the:

Industrial Design Center

This area has been here for a while, and sits above the road bike product development team’s office, which decided to keep their doors shut during the tour. On hand were a couple of the mountain bike designers and engineers, who said it takes 2-3 years to design a new bike. So basically as soon as they finished the 2015 version, they started work on the new 2019 Stumpjumper.

If you look at the lineup, everything from the Epic FS to their Demo (left to right), the lines are similar. Does this mean the Epic and Enduro will get the Sidearm treatment? Time will tell, but if it provides the desired improvements, we’d say it’s possible.

They do hundreds of sketches and use art boards with cool things from other industries and sports.

The new Stumpy was, in a large part, designed around making the cable routing easier. Although, that wasn’t the impetus for the Sidewinder brace. They wanted the frame to flow both visually and structurally from your hands to the rear axle, and provide a better connection between hands and feet so that what you’re feeling at one end of your bike matches the other end. Which should give you a better sense of what the bike is doing.

They come up with a lot of ideas, so they want to be able to iterate quickly. Which is why they have such a large design center and workshop, so they can make stuff and test it quickly, moving through concepts to see what works without waiting around.

Their industrial design folks work with the engineers to find solutions that both work and look good. Sometimes it’s not hard or complicated, it just takes asking the question of how something could be better. Or quieter. Or prettier.

While that sounds fun, they admit that sometimes it gets “interesting” when trying to balance design versus engineering, and sometimes it takes extra effort because both sides fight for what they think is best for the rider… and both sides are very passionate. They say one of the biggest challenges is just getting it done and into production because they want to keep making improvements.

Speaking of pretty, they use rider profile boards to come up with color schemes. They also work with the SBCU crew to see what’s working in the shops, then that feedback is incorporated into the potential options. The Art Board then turns into a project board to add a graphics strategy. They consider graphics across the product range, too. If you pay attention, the graphics on the new Stumpy mimic what’s on the 2FO shoes, which are a good fit for the Stumpy rider.

By the way, the color concept for 2019 is “illumination”, which to them means dark, rich colors with bold, bright highlights and accents.

Research & Development Lab

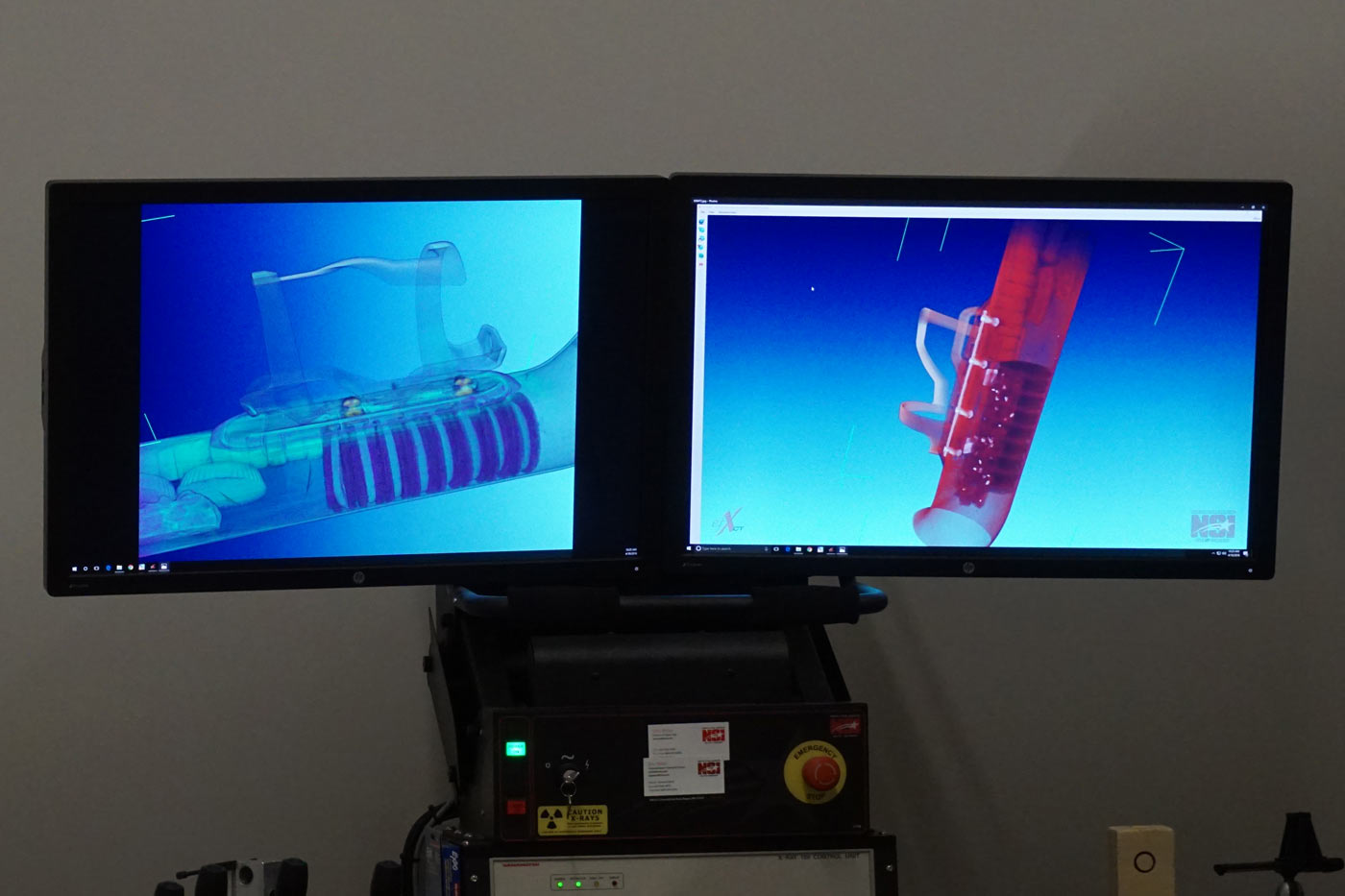

They have a room full of 3D printers and associated apparatuses, letting them rapid prototype anything in plastic. The room behind it has this CT scanner, which lets them check carbon layups and see what’s really happening inside a frame.

It’s also how they tuned the design of the new SWAT door.

The full machine shop opened in the past couple months, which is what allows them to do a first build on things they want to do. Or to test the kinematics on a new suspension design.

What started with this Bridgeport milling machine…

…has become a complete workshop with four modern CNC machines and two EDM wire cutters. The DMU 85 is a million dollar machine by itself and is used to quickly prototype complex 3D parts in just two steps. This lets them machine new linkages to test things with a 24-hour turnaround from when their pro riders give them feedback to getting them back on the dirt. They say they could make a full frame out of billet if they wanted to.

The EDM wire cutter lets them produce highly detailed parts like these internal collets for the Command Post dropper seatpost. From here, they have to figure out how to mass produce them, but this first step lets them test and iterate in house. They also used it to cut away material from the prototype shock yokes on the new Stumpy.

They also make the sweet signage hanging throughout the department and adorning desks. More practically, they can also make their own carbon molds…

Carbon Fiber Lab

Not only can they layup a complete bike using molds made on site, they use these facilities as proof of concept for manufacturing capability. When they first floated the idea of the new Stumpy frame by their factory, the factory said no way. No way could you do that with cable routing. No way could you put a giant hole in the downtube and make it all stiff enough without being a tank. So, they figured out how to do it first, then showed the factory how.

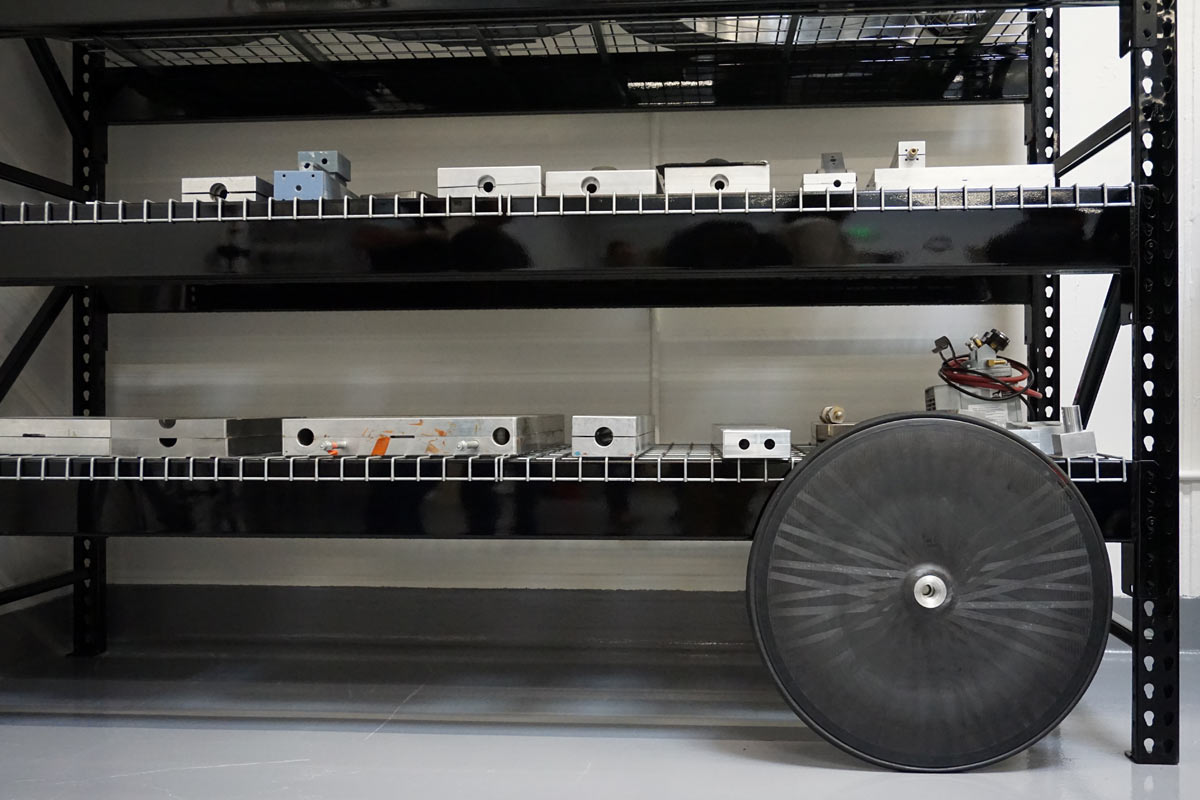

A rack full of molds suggests they’re making good use of the new toys. And yes, that’s a full carbon prototype disc wheel they made there.

The heat press is off in a side room, which compresses and heats the carbon so the layers bond together while having the air sucked out by vacuum.

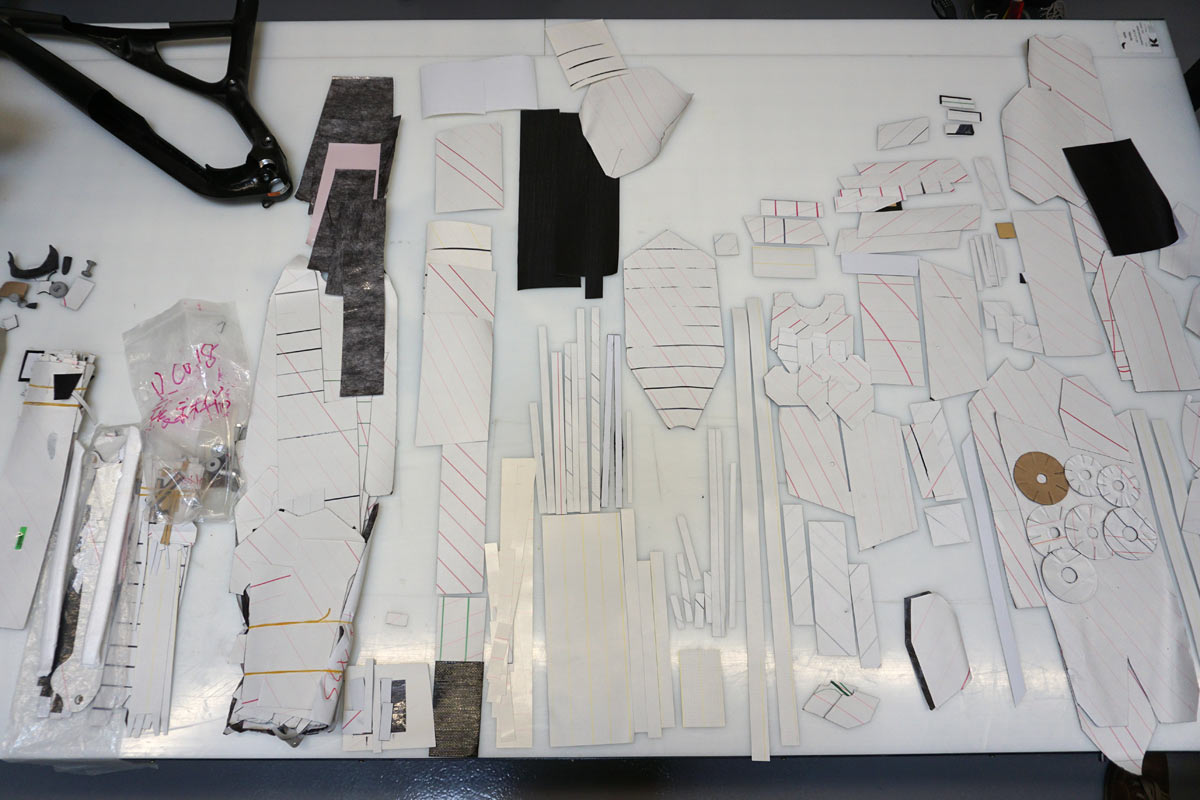

These are the 400+ layers of carbon that go into a 2019 Stumpjumper frame, which takes about three days for them to layup there. It’s probably faster for their manufacturing partners, but still…that’s a lot of parts. Just out of frame are some unique internal molds that they didn’t want shown, which use a proprietary design and method that’s exclusive to them and their factory.

The result of all that effort is a prototype frame they can take around the corner to the:

Specialized Test Lab

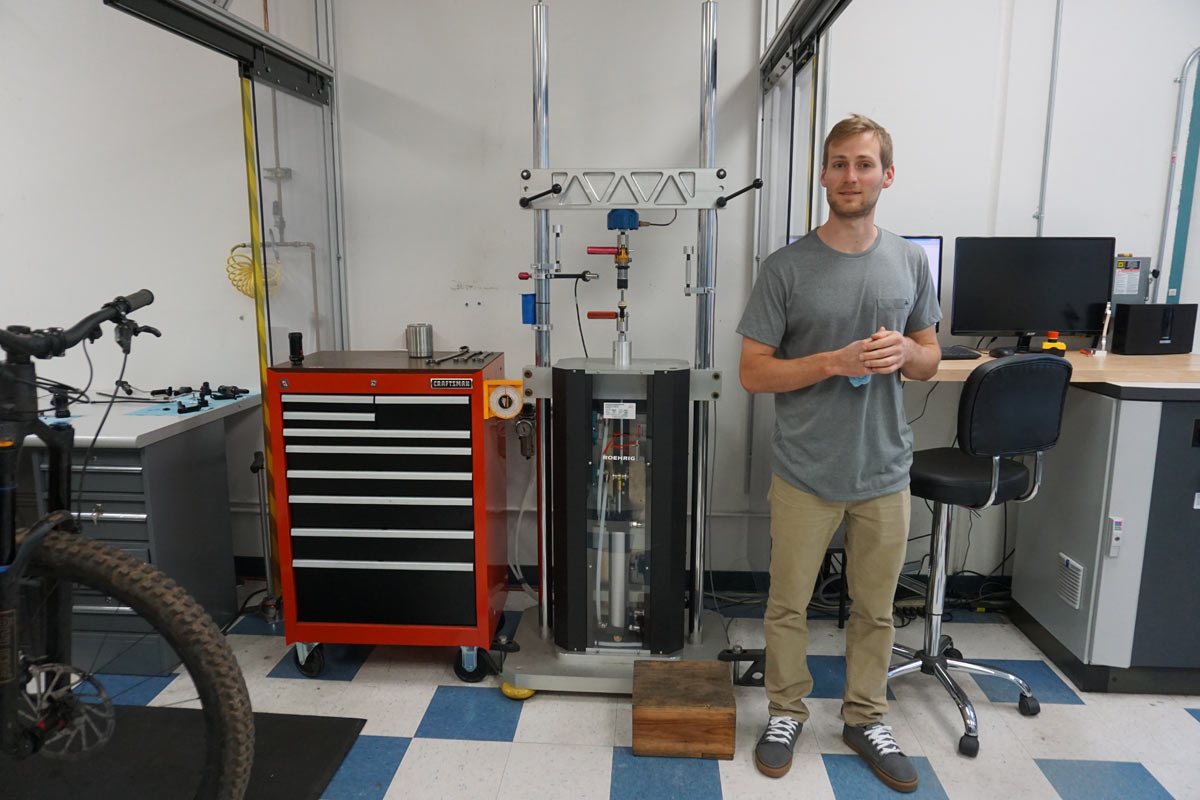

Standing to the right with the red beard is Erik Kristiansen, test lab manager. He’s in charge of the machines that test stiffness, durability, etc. Having it onsite let’s them test it quickly before wasting a lot of time designing something beautiful only to have it break months or years into development.

There are duplicate identical test labs in Vietnam, Taiwan, and China. They test every size and version.

Stiffness testing is first, measuring deflection down to 1/100th of a millimeter.

This mule kept getting layers of carbon added until they found the right stiffness, which provided the baseline for getting final layups concocted.

Then they go to fatigue testing. The new Stumpjumper frame went through 600 tests to get the frame where they wanted it and prove it was safe and durable. All of their carbon bikes are rated to ride 90 minutes a day, five days a week, for 10 years. They closed with this: “Most every frame that comes in here gets broken.”

Suspension Labs

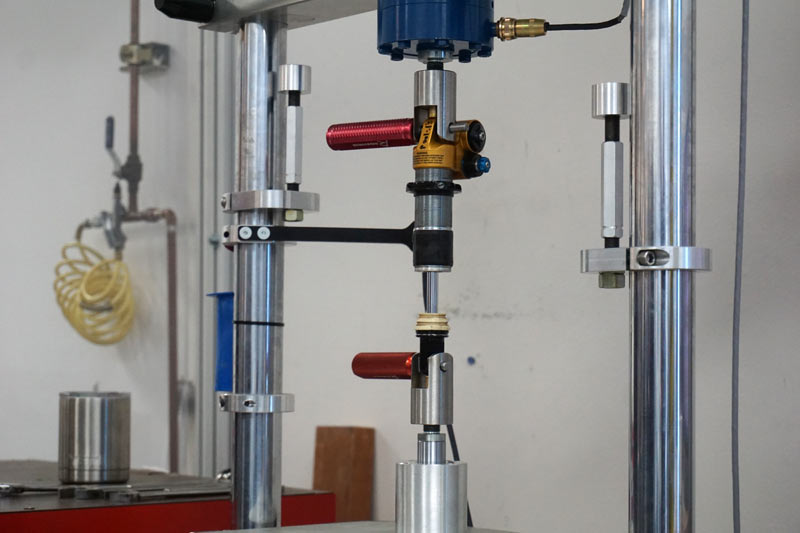

Specialized’s BRAIN suspension was developed here, and they run their RX Tune custom tuning program here, too.

This alloy kinematics mule lets them make micro tweaks to the pivot points to get the leverage ratio right, then they move on to air volume testing. Since they’re developing the BRAIN shock, they create the shim stack, port size and shape, valving, and other items to get the tune how they want, them they send that info Rockshox (or Fox or Ohlins for non-BRAIN shocks) to have them made to their spec.

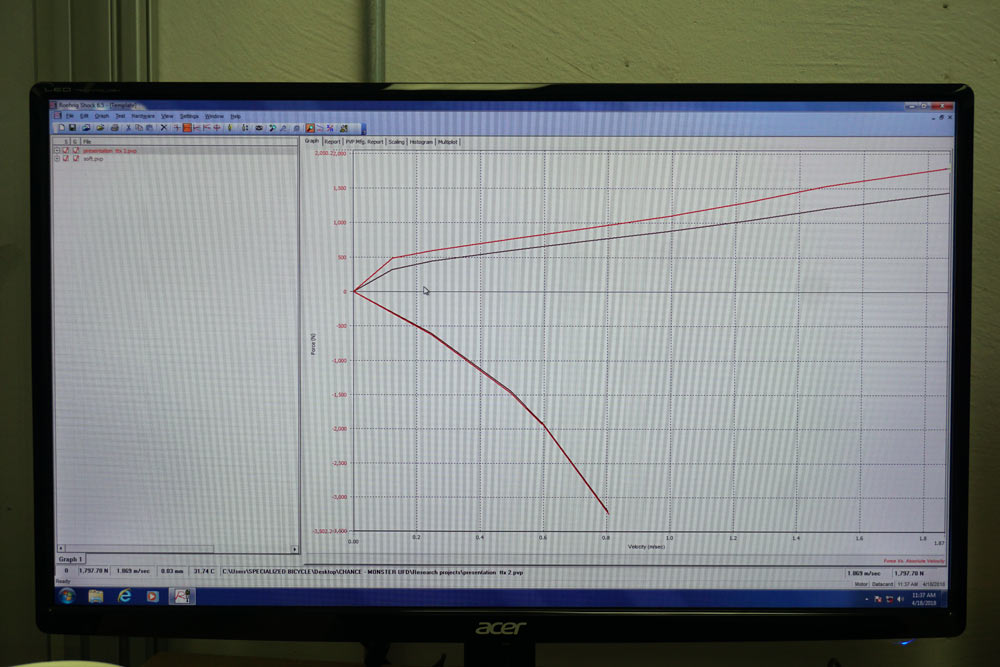

The dyno tests the shock at real world speeds, from slow and flowing to rapid, repetitive hits, then charts it on the computer to see how the shock performs in various compression and rebound damping settings. They do the same amount of testing for low end to high end shocks, because as they say, “there’s no reason any shock should ride like shit.” That means even their affordable bikes should ride well right out of the box.

For their pro riders, they could tune with various oil weights, too, but mostly just work with the shims and stuff. They’ve also tested long travel Baja race truck shocks for a team they sponsored, as well as different rubber compounds (presumably for tires) to see how they flexed, rebounded, etc.

Custom Paint, Builds & Employee Bikes

No visit to Specialized HQ would be complete without a look at some of the crazy custom bikes and special paint schemes lining the halls. Literally, everywhere you look there’s an Easter egg to be found.

No visit to Specialized HQ would be complete without a look at some of the crazy custom bikes and special paint schemes lining the halls. Literally, everywhere you look there’s an Easter egg to be found.

This Levo fat bike was turned into a quasi cafe racer with re-branded Vee fat tire slicks, extra lighting and a temporary rear fairing until the owner can convince the R&D folks to make him one out of carbon fiber.

Some builds beg the question “why?” and others have obvious merit.

Their paint shop tests different concepts or just likes to flex their creative muscle now and then. When something doesn’t get into production, those frames are sold to employees. And sometimes, employees can request a custom paint scheme. Or, if you’re the owner, you can kinda get whatever you want. This color-changing purple-to-blue metallic Stumpy is none other than Mike Sinyard’s new bike.

Huge thanks to Specialized for showing us around!