SRAM has published a patent (originally filed last summer, on June 23, 2021) detailing a suspension fork with an automatic venting system, wherein differential pressure arising between the ambient environment and the cavity inside the lower legs would self-equalize while riding. The invention, we imagine, would likely replace the rider-operated lower-leg pressure relief valves found on 2023 Rockshox ZEB, Lyrik, and Pike forks. The auto-venting system would have the exact same purpose as those bleed valves, but wouldn’t require any input from the cyclist, aside from simply riding the bike over uneven terrain. The published patent document details a number of separate design concepts (or embodiments) that could each be implemented to achieve this new automatic function, a few of which we will outline here…

SRAM Suspension Fork with Automatic Venting

Remember when Fox filed legal action against SRAM for the use of lower-leg bleed ports on their 2023 Rockshox Suspension Forks? The former claimed that SRAM were infringing upon their own patent (#9739331) which describes the use of valves operable by the rider to equalize pressure between the ambient environment and the space inside of their fork lowers. The valves serve to relieve pressure built up inside the lowers during hard riding (and thus, temperature changes), or indeed any pressure differential between the two environments, as which would also arise from elevation changes, or traveling from one extreme of weather to the next with your bike.

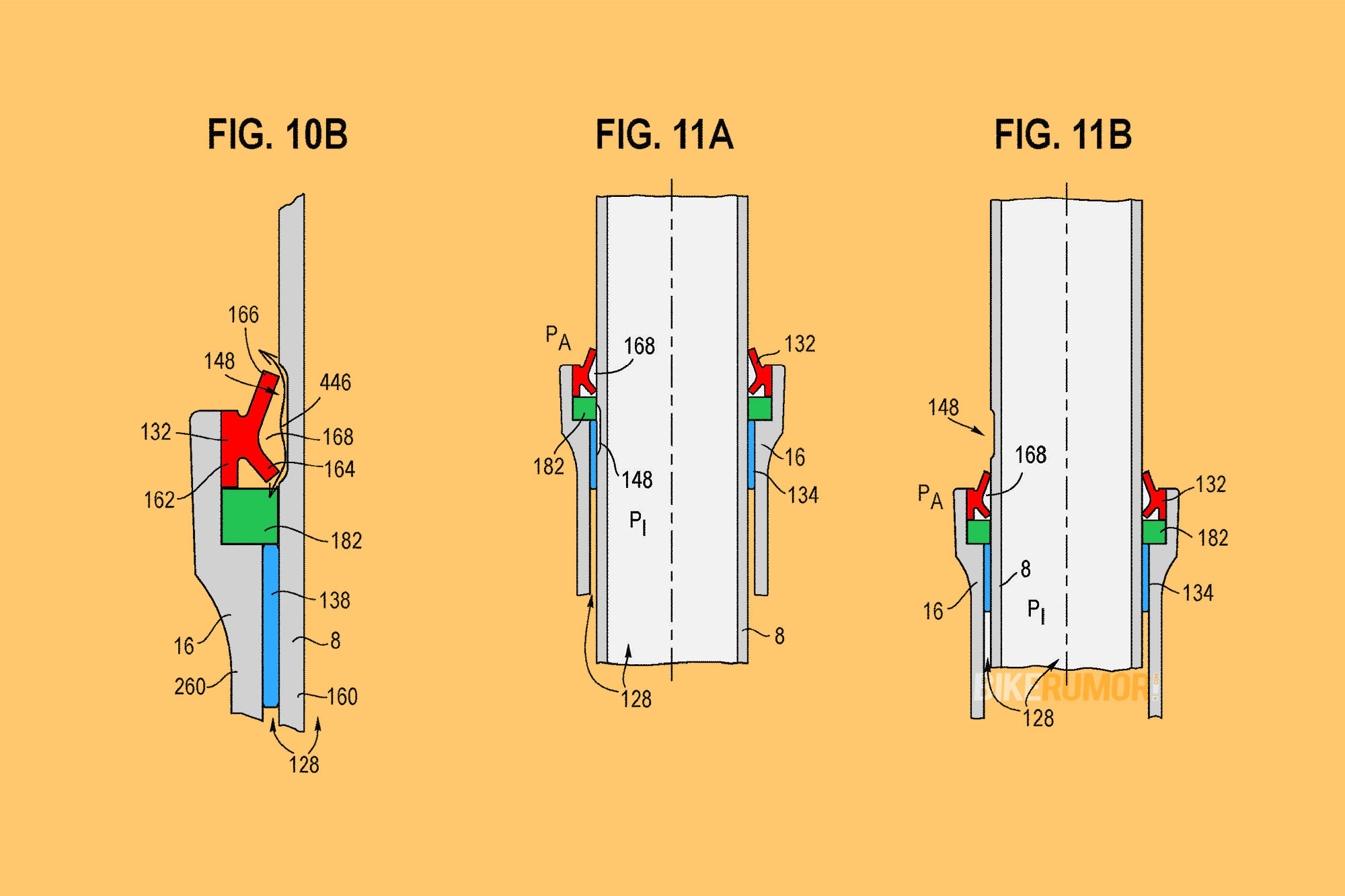

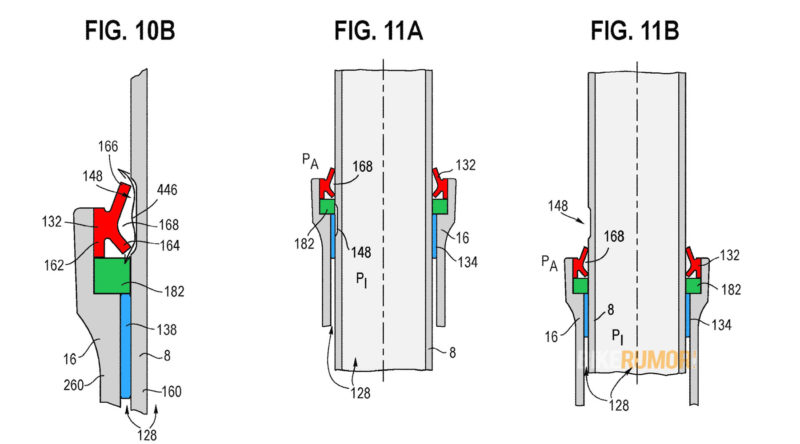

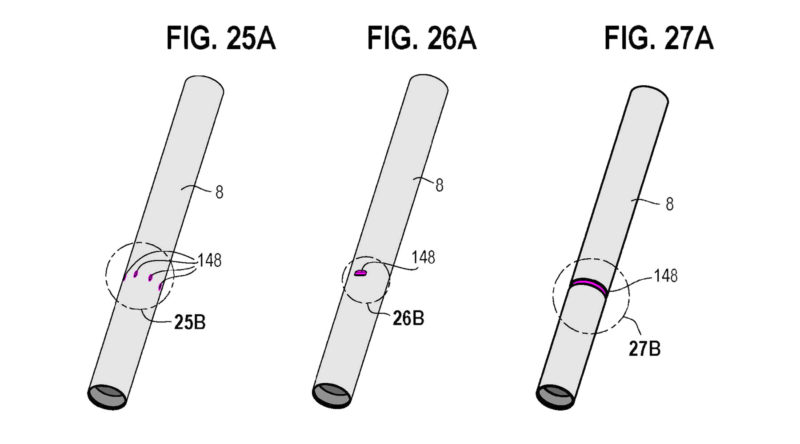

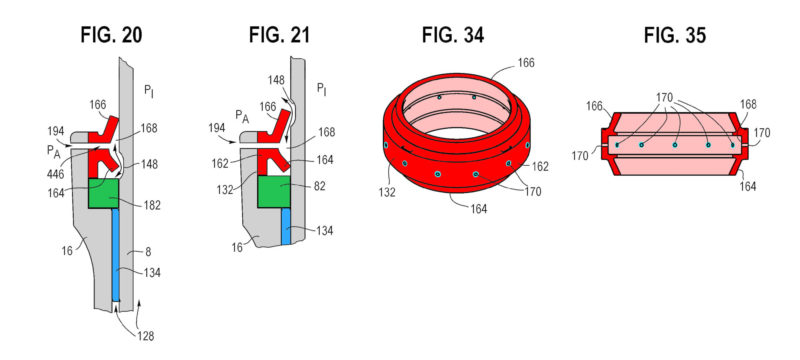

A new SRAM patent (US 20020411007) published December 29, 2022 describes an automatic venting system for a telescopic suspension fork that eliminates the need for any rider input, aside from riding the bike as normal, that is. A few designs are described within the document, but most seem to center upon dual-lipped k-shaped wiper seals (red, in our illustrations) between the lower legs and the stanchions that are able to transfer pockets of air (168) between the ambient air pressure of the outside environment and the air otherwise trapped inside the fork lowers.

How? By virtue of a series of dimples, or an annular recess (148, below), positioned on the stanchions themselves.

In those designs, the simple telescopic movement of the stanchions relative to the lower legs during compression and rebound events would allow an exchange of air between the two spaces, equalizing any pressure differential that may exist as the main K-seal passes the dimples. Importantly, in all designs, airflow is bi-directional.

Of course, if air can be exchanged between the two environments, then it stands to reason that moisture, dirt, and oil could, too. The patent describes use of an “air permeable absorbent” material (green, in all figures) sitting just underneath the dual-lipped wiper seal that would prevent any lubrication oil inside the lower legs from escaping. This sounds much like a generic foam ring that would be found inside any modern suspension fork. The document says this component could be made of closed-cell foam, open-cell foam, or a sponge material formed from polymer-based materials. Underneath the air permeable absorbent ring, the patent describes the use of a conventional bushing (blue, in all figures) with a small split to allow the passage of air between the spaces above and below it.

Seems to us from these diagrams that, in order to prevent the stanchion recess from dragging debris down into the lowers, the whole stanchion would need to be protected with some kind of flexible boot. Without that, the recess would simply serve to fill the dual-lipped wiper seal with any debris that ended up on the stanchion, blocking it such that there’d be little exchange of air anyway.

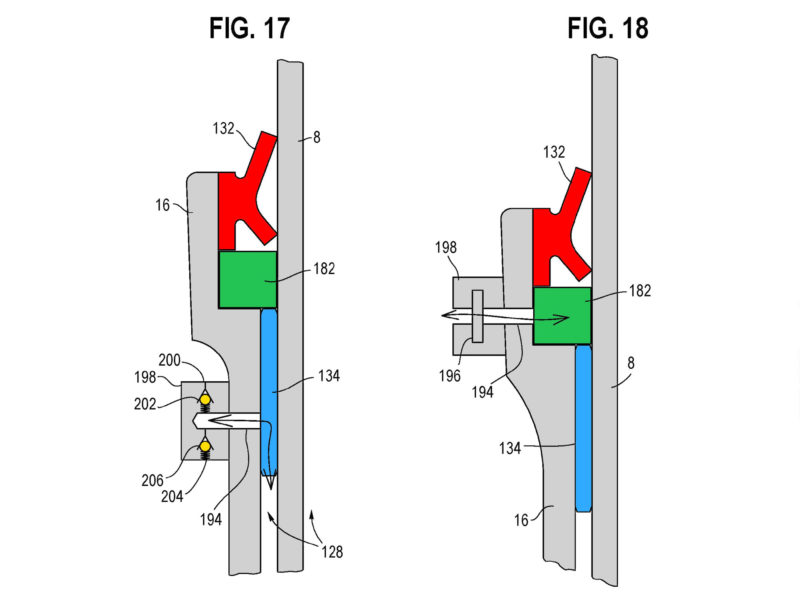

However, another version of the automatic venting system lacks these dimples, or annular recesses, on the stanchions. To equalize any pressure differential, an outlet port is positioned further down the lower leg. It offers a pathway for bi-directional airflow between the lower leg interior and the outside world, with (Fig. 17) or without (Fig. 18) use of an inlet valve and an exhaust valve (yellow) that could be configured to open at respective pre-determined pressure differentials. This embodiment looks a lot more like the pressure relief valves in use on the 2023 Rockshox forks, though it seems they would equalize any pressure differences automatically, without the need for the rider to press a button.

One can imagine a scenario wherein pressure builds up inside the lower legs during a long descent, and when it reaches a threshold value, the exhaust valve is forced open to allow that pressure to “blow-off”. This would simply happen while riding, so the rider would not have to suffer any additional undesirable ramp-effects coming from the lower legs. And therefore, they would get much more consistent performance from the fork, I imagine.

For enduro racers at least, this could be preferable to user-operated lower-leg bleed ports/pressure relief valves. I mean, consider that EWS racers are frequently subjected to hellishly long stages that can often take more than 15 minutes to complete, covering lots of elevation and measurable heat build-up in their forks. That said, without those user-operated bleed ports, it may not be so easy to equalize pressures resulting from significant changes in elevation.

There could be a way around that, however, particularly in the design that relies upon those dual-lipped wiper seals and dimpled stanchions. If the dimples (and thus air by-pass volume) were positioned around the sag zone, the rider would simply need to bounce up and down on the fork a few times after hopping off the chairlift in order to equalize any pressure differential that may have arisen on the journey to the top.

Where is SRAM going with this?

It’s hard to say, really.

It seems the dual-lip wiper seal-dimpled stanchion combination could necessitate the use of a fork boot to prevent dust, water and dirt ingress, lest all the dirt that regularly sits on top of our wiper seals get wiped inside the fork. And we can’t really see Rockshox going down that route.

However, the lower leg valve with automatic exhaust vent seems to be a more plausible design that would be less likely to result in contaminants entering the lower legs. And, if executed as described by the patent, we reckon it could eliminate that end-stroke ramp effect that often stops riders from accessing the last precious few millimeters of travel. Going further, it could even improve the consistency of a suspension fork’s performance on a long rough descent.