As much as we love diving deep on suspension design and technologies, it’s important to get the basics straight. Last week we covered undamped suspension forks. But that’s not the norm anymore, so what is suspension damping in the first place? Most modern mountain bike suspension includes hydraulic damping, but that hasn’t always been true. What does damping do? And why do we need it?

What is Suspension Damping?

Mechanical damping is essentially the core principle of modern suspension, whether it is on a bike or in something larger and heavier, like your car. An impact hits the wheel and then a shock including some type of spring absorbs that impact before it makes it to the rider. The spring – whether it is a physical coil spring or air being compressed – would naturally bounce back with the same force being input, and then oscillate back and forth (like a pogo stick) until friction in the system stops any movement. That’s not really ideal in most circumstances, so that is where damping comes into play.

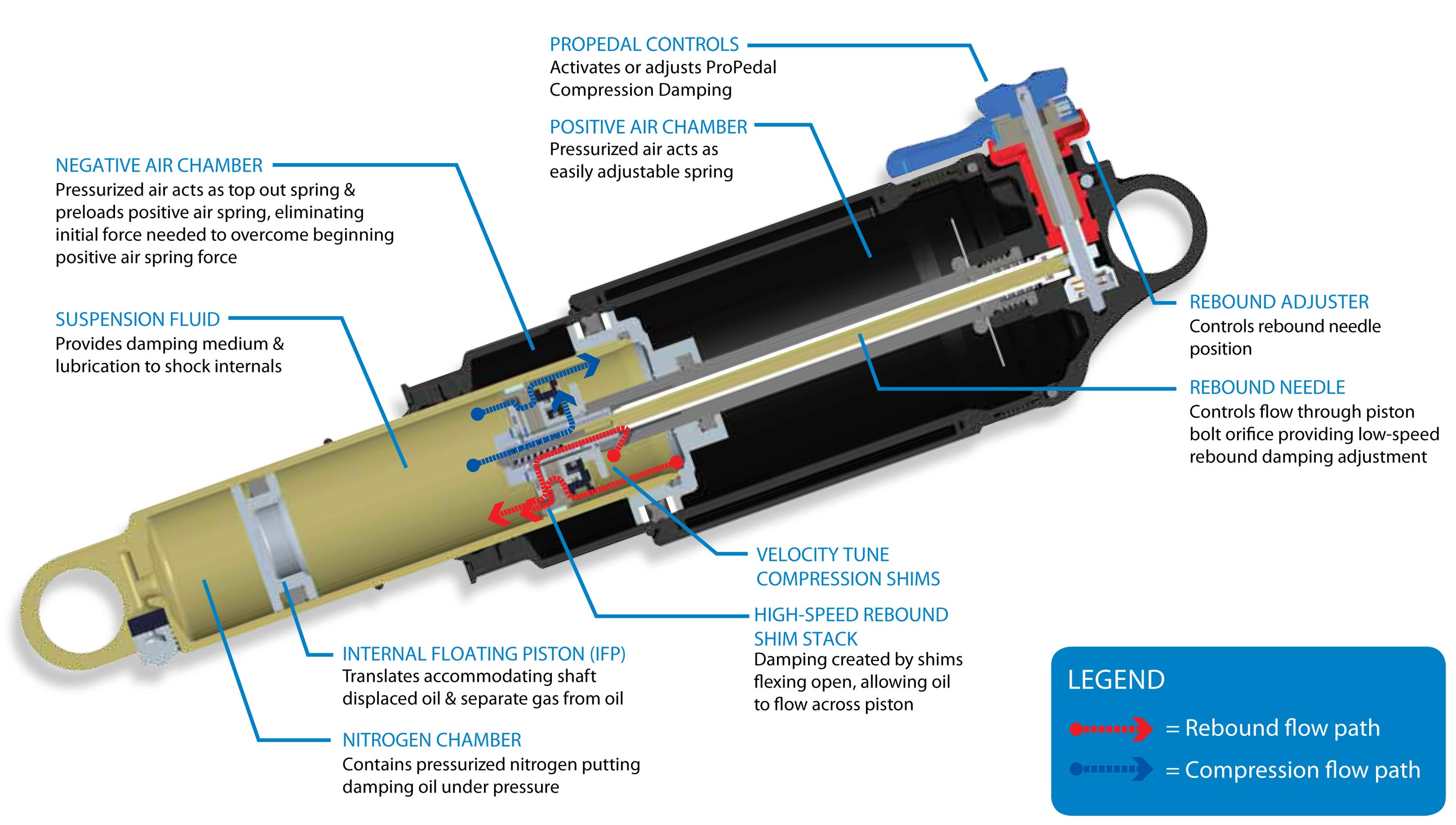

Suspension damping is the process of controlling or stopping the spring’s oscillation, either when it compresses or rebounds (usually both). This typically works by introducing a hydraulic cartridge into the mix, with a fluid and some controlled valving. As the spring is compressed, damping fluid (usually oil) moves through a series of valves from one chamber to the next. By forcing the fluid through different size and shape ports, shims and tunnels, the damping cartridge can control the compression and rebound speed… or stop it altogether. This is all done so the spring doesn’t compress or bounce back too quickly. And so it will stop bouncing altogether between impacts.

Where is the damping in bicycle suspension?

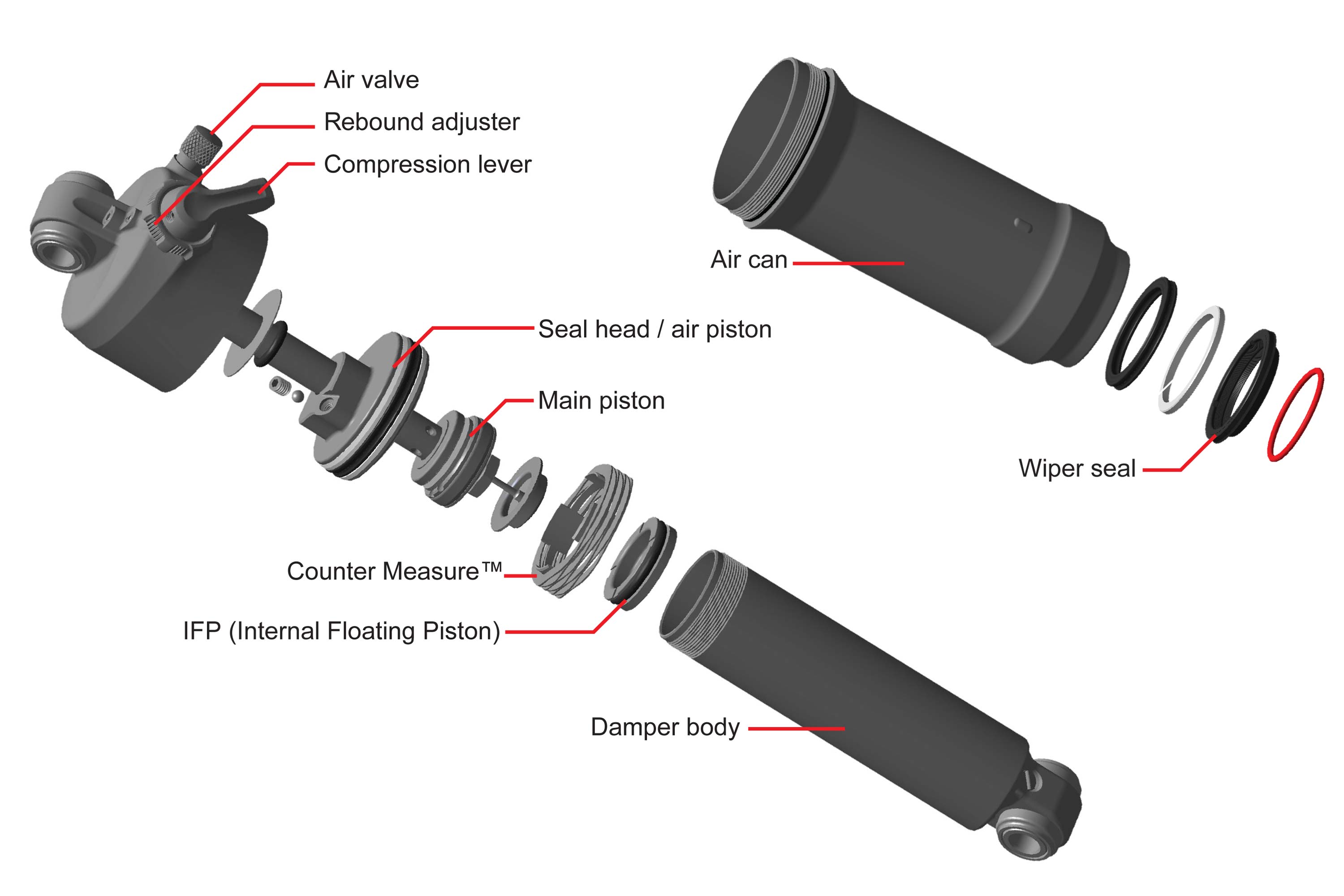

On a full-suspension mountain bike, damping exists in both your fork and your rear shock. Up front in the fork, often one leg gets a hydraulic damper and the other leg gets a spring – either air or oil. Out back, the frame’s shock typically combines an oil damper body and the spring into the single telescoping shock. An air shock like the Fox Float or RockShox Deluxe puts the hydraulics in the lower slider, while the larger outer body (or air can) houses the air spring (above).

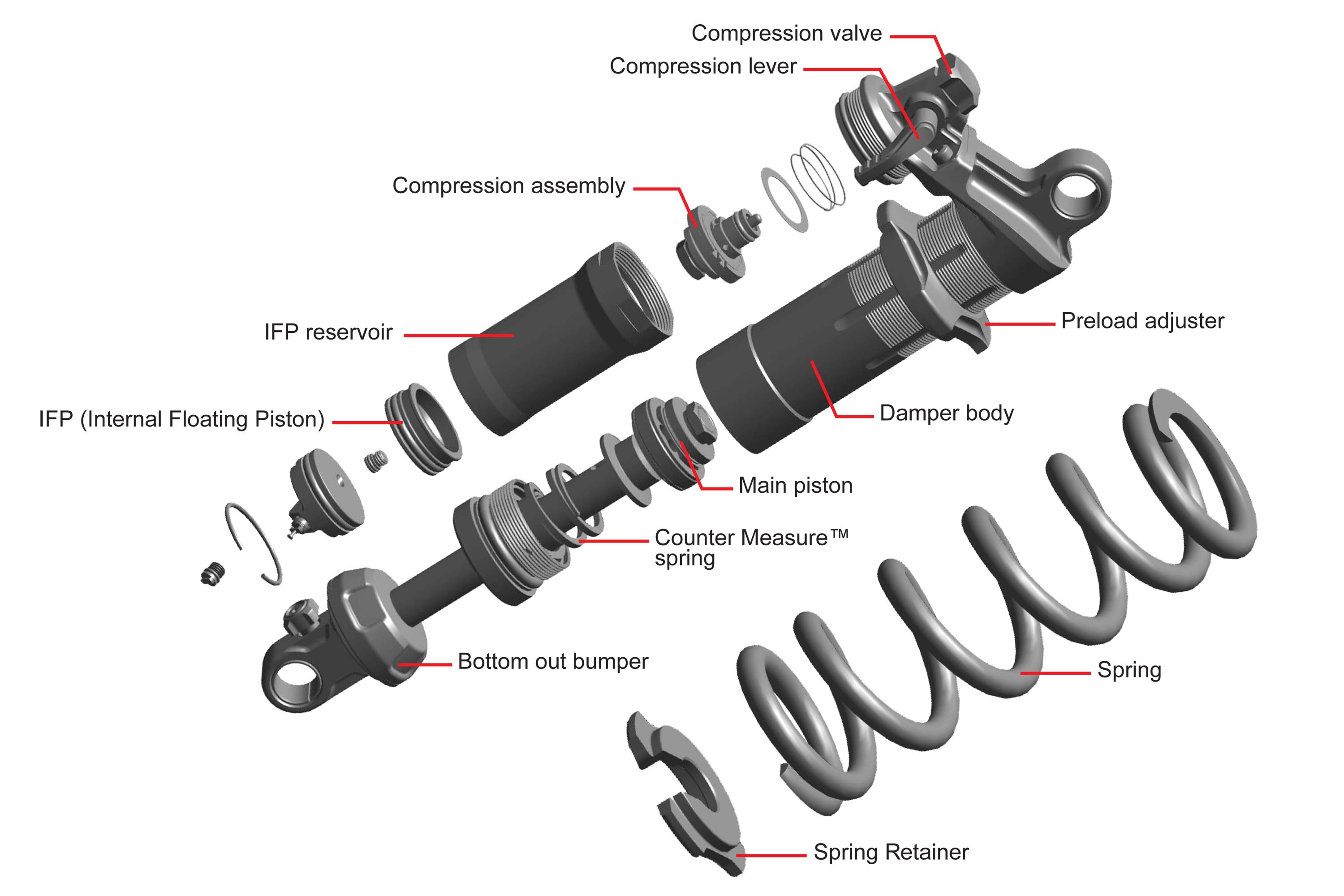

In Coil shocks on the other hand, like the DHX series or Deluxe Coil for example, the hydraulics take up the body of the shock with a coil spring pretensioned onto the outside of the threaded shock body (above).

What is Compression Damping?

We talked about it in detail when differentiating between high- & low-speed compression, but to simplify it – Compression Damping is your shock slowing down and absorbing some of that impact force as it the suspension compresses. Again, this works by the controlled flow of a suspension fluid though a damping circuit. That circuit might use ports, valves, shims or springs to control the fluid’s flow rate and patch. Most modern suspension uses a combination of these to provide separate high (big hit) and low (small, slow hits) speed compression damping.

By changing/tuning compression damping you can control the rate at which the suspension compresses in response to an impact, adjusting it to suit your riding style and the type of impacts your bike will encounter.

What is Rebound Damping?

Rebound Damping is essentially the same thing in reverse – controlling the shock as it rebounds to its natural, uncompressed state. The damping here is what stops the shock from just immediately bouncing back after you hit something to compress it. We went deep into high- & low-speed rebound controls as well last fall. Adjusting rebound damping controls the rate at which the suspension bounces back to normal to be ready for the next impact.

How does damping benefit a mountain biker?

The primary function of damping is to lessen the speed or intensity of the impact transmitted to the rider for improved comfort and control. By slowing the force of an impact and transmitting it over a longer period of time it is less of a stress on the rider. And by converting input force into heat that can dissipate inside the suspension fluid, the rider doesn’t have to be subjected to some of the force of the original impact.

From the compression damping perspective, that can both ease the force of a large impact and keep the suspension from bobbing from your own pedaling inputs. On the rebound damping side, it makes the bike easier to keep under control after an impact and ensures that the suspension returns to an uncompressed state quickly enough to be ready to absorb the next impact, so it won’t get bogged down over repeated bumps… but not so fast that it bounces the front wheel off the ground, causing a loss of traction.

Does suspension damping work the same for all cycling disciplines?

Generally hydraulically damped suspension functions the same no matter what type of bike it is on. But the ability to independently adjust how both the compression stroke and rebound of a shock function at several different levels or speeds (more than just high- & low-speed in the most advanced suspension components) means the function of damped suspension varies widely from something like the electronically damped rear shock of an eDSS-equipped Pinarello road racing bike to the prototype coil suspension of a World Cup winning Transition downhill bike. While the means may change from one application to the next, the end goal remains the same: Keep the tires glued to the ground!

And that brings us back to where we were last week. Some modern alternate suspension designs omit active damping altogether, like that fork. As Lauf founding engineer & CEO Benedikt Skúlason reminds us those “suspension systems are actually not undamped”. The suspension design and components just don’t include active damping. “The rider and the tires provide the required damping.” You as the rider damp the suspension inputs so they don’t keep bouncing up and down forever, as do the tires, and at times the material of the frame and fork as well. While that doesn’t make sense for the big impacts of downhill racing, the theory has merit (and it seems to work from our own experience) in less technically demanding environments like road, gravel, and some smoother cross-country riding.

The fun never ends. Stay tuned for a new post each week that explores one small suspension tech, tuning or product topic. Check out past posts here. Got a question you want answered? Email us. Want your brand or product featured? We can do that too.