Welcome to Tire Tech, Bikerumor’s mostly-weekly series on bicycle tires. Like our Suspension Tech and AASQ series, we take your questions about tires, whether it’s road, cyclocross, fat, plus, gravel, or mountain bike, and get answers from the brands and people behind them.

Last week we took a break from the academic side of our Tire Tech series to talk tire history with Mountain Bike Hall of Famer, Tom Ritchey. He provided an interesting look into how mountain bike tires evolved over the years and how his experiences guide his product development. This week we catch up with him again as he walks us through the technology of tread patterns past and present.

Unlike most manufacturers who release new products based on trade show calendars and marching orders from top executives, Ritchey lets the market need dictate new product development. When the time comes to introduce a new model, he has a defined process he follows.

Establishing the design parameters

The first step is assessing the type of tire needed and its specific performance objectives. The width of the tire and rim are the initial considerations. Next is the target weight. This is a critical element as it drives casing choices, rubber compounds, and tread designs. The conditions for which the tire is designed play the most significant role in the development of the tread pattern. This is where Tom Ritchey might have an edge over other designers.

During our conversation about the genesis of the Ritchey brand, racing was a reoccurring theme. Ritchey tires where developed on, and for, race courses around the world. During the early years of World Cup racing, course conditions varied wildly. As Ritchey said, “It wasn’t uncommon for a rider to win one race and get blown out the next because the conditions didn’t suit their tires.” For that reason, Ritchey designed tires for every conceivable scenario. Today’s racers have it a bit easier with somewhat standardized race venues. Suffice it to say, Ritchey has made tires for everything from hardpack to peanut butter mud.

The actual shaping of the knobs begins in a 2D sketch but there are defined guidelines Ritchey follows. For years his tires have adhered to a design principle called Vector Force Analysis (VFA). This isn’t buzz-word marketing spin, it’s good scientific theory. In lay terms, VFA is the analysis of forces applied in specific directions or vectors. That naturally drives the orientation of the knobs, which in turn gives a tire an optimal direction of rotation. As Ritchey said, “The forces applied to a bike tire are dynamic and varied. The tread has to be designed to counteract each of those specific forces.”

Shaping the knobs is guided by VFA and one basic objective—to place the maximum amount of lug face perpendicular to the force angle. Placement of the lugs is heavily influenced by lean angles and the parabolic shape of the casing. These are things Ritchey applied to tread designs ahead of the competition, but are widely used now.

Sculpting the Tread Blocks

As the tread pattern comes to life, the overall weight becomes increasingly important to the process. The best way to cull grams is to shed rubber. This has to be done with careful calculations. Ritchey went on to explain, “If too much base rubber is removed there is a greater chance the lugs could simply sheer off.”

Shaping of the lugs invites careful calculations and assessments of the ballance that has to be struck between too much and too little. Large voids reduce weight but limit the amount of knob edge connected with the trail. Small blocks also reduce weight, but may not provide enough edge surface to brace against perpendicular forces. The height of the knob has to be considered. Too tall and the knobs lack support and once again add too much weight. Not tall enough and it won’t be sufficiently effective.

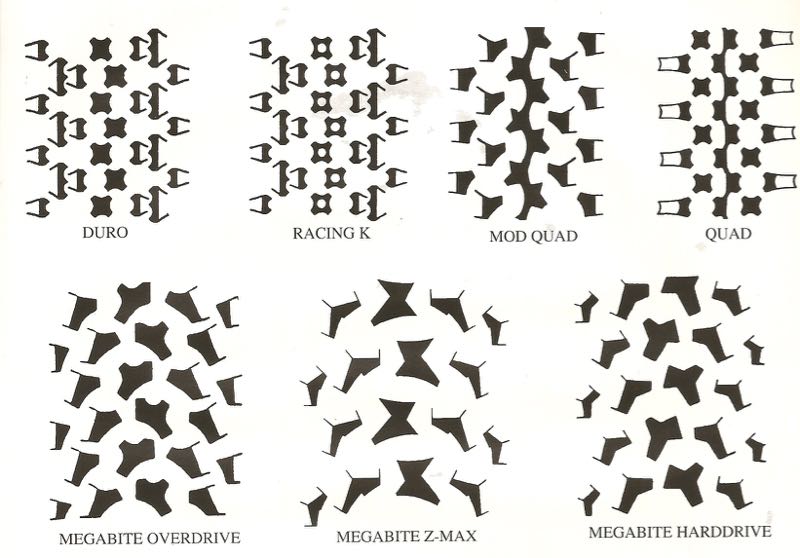

When asked about the precise sculpting of the knobs from one tire to the next, Ritchey offered an unexpected response, “They are all derivatives of the same family of lugs which were created using the VFA principles long ago.” It is true a Ritchey tire is easily identified as such. There is a reoccurring rhythm of angular features in every pattern. You’re not likely to see round Onza-inspired knobs on one of Ritchey’s tires.

When asked about the iconic Z-Max, Ritchey said, “The Z-Max may never be retired. Over the years the size and shape of the blocks have changed slightly, but it’s mostly unchanged. Once it was sorted, it was great. Those same tread elements are found throughout the line.”

With the general tread design drafted in 2D, Ritchey makes a 3D model. “The ability to hold a 3D model often allows me to see things I may have missed in 2D.” This is something we’ve heard from other product engineers. Modern tools have greatly simplified the prototyping and modeling of early ideas. Once the design is approved, it gets made into test samples.

With facilities in Taiwan, Switzerland, and Northern California, all three are capable of testing products, but Ritchey still does much of it himself. He is as active on the bike as ever and that passion is evident in the products he designs. And make no mistake, he is the lead designer on every project.

Of the qualities Ritchey feels are most important in a tire, predictability is the most critical. Any uncertainty in tire feedback compromises rider confidence and their ability to push the bike to the limit. Determining the efficacy of a tire is still left to skilled evaluators because as Ritchey pointed out, “No one has yet to design a machine that can objectively test a tire. It is still a subjective process.”

It’s not often I get to bend the ear of one of the most influential personalities in mountain biking, but I had to ask one last question. As far as we’ve come with tire development, I wanted to know if he thought we were at the zenith of tire tech. He didn’t pause for long and said, “Yes. We are likely near the pinnacle of what we can achieve with current compounds, tread patterns, and casings.”

Somehow, I don’t think that will deter Tom Ritchey from improving on his tires.

Pumped on this? Got a tire-related question you want answered? Email us. Want your brand or product featured? We can do that, too.