It’s not often the humble spoke gets much attention, unless it breaks and ruins a ride, in which case your attention is very much directed to that most voluminous part.

The new Pillar 3D Force spokes should further reduce the attention you pay them. They use two flattened sections near the J-bend head that increase the fatigue life by 3-5x normal.

It works by placing alternating flattened sections that first absorb the torsional stresses on the spoke, and the second absorbs the bending stresses. These combine to relieve the two forces in the area where most spokes snap, giving them the enhanced durability…

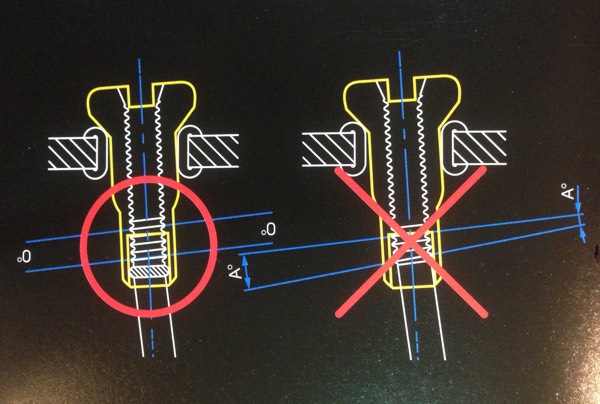

To go along with it is the TAF nipple, which incorporates a semi flattened thread area at the top of the nipple where the spoke first enters.

The idea is the spoke’s threads screw in well past that point once the wheel is built, leaving the flat area of the spoke to rub any threads and potentially weaken it. Now, there are smoother, flatter edges to reduce abrasion on the spoke and help prevent breakage.