Last week, we reported on the announcement of Trek’s new Roscoe Gen 4 hardtail mountain bikes. In the press materials, Trek mentioned it was using its latest Alpha Platinum Aluminum, an alloy it claims has lower emissions than aluminum it has used in the past. We first learned about this low-impact aluminum program earlier this year in the brand’s 2024 Sustainability Report, but now we’re starting to see more frames made with it hit the market.

Starting in October of 2025, Trek says that “nearly every aluminum bike frame from Trek, Electra, and Diamant will be made with aluminum that is sourced from facilities powered by renewable energy, incorporates recycled material, or both.” Trek goes on to say, “This shift impacts well over 1,000,000 bikes annually and is the largest carbon-reduction initiative in Trek’s history. The switch to low-emission aluminum is a major step for the company in reaching its sustainability goals.

Why Aluminum?

Trek has been very open about its environmentally-oriented initiatives since it completed its first emissions audit and sustainability report back in 2021. Ultimately, the brand set forth numerous emissions reduction initiatives that are quantifiable and trackable to hold itself accountable. Like any bike brand, Trek doesn’t exist in a vacuum, and reducing its emissions involves much more than switching its headquarters to renewable energy sources or credits.

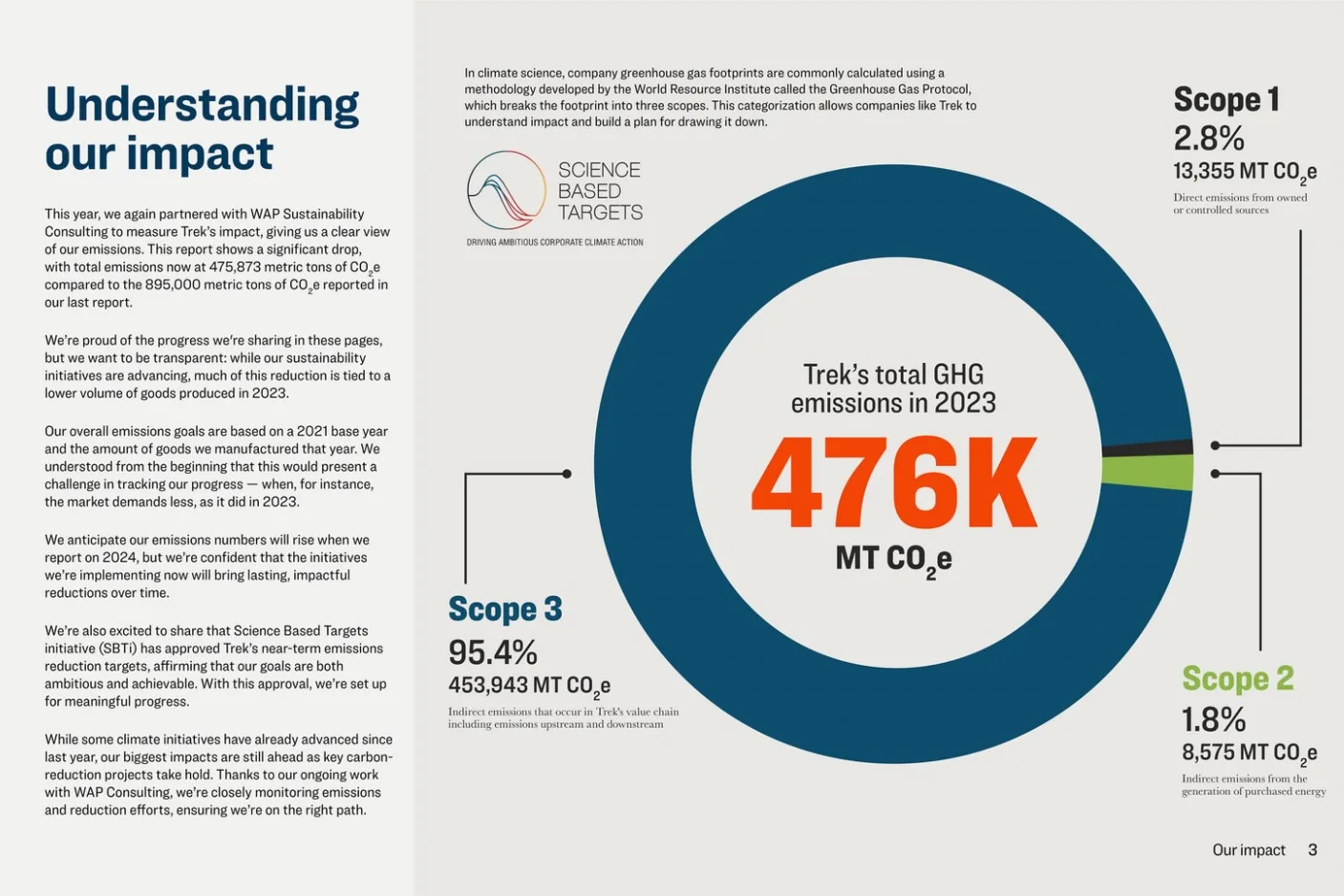

While riding bikes is generally considered good for your health and the planet, producing and selling them obviously requires numerous parts and components, all of which require their own materials, production facilities, energy resources, transportation, packaging, etc. Supply chains are not simple things, and Trek claims that roughly 95% of its emissions were from its supply chain.

In that supply chain, Trek learned that aluminum was the largest contributor to its overall greenhouse gas emissions, and addressing that could have the largest impact on its total emissions. So, the brand began examining ways to lower the impact of its aluminum starting at the source. In doing so, Trek hopes the frames and components produced by the new low-impact aluminum “will produce only about a quarter of the emissions of previous materials.” That’s a very ambitious goal, and one that the brand says it is already making headway toward.

New Aluminum Sourcing Policy

The biggest shift Trek has made is a new aluminum sourcing policy requiring suppliers to meet certain criteria and “ensures our partners in the supply chain are as dedicated as we are to lowering emissions and having a positive impact on the planet.” The primary criterion is the use of renewable energy at the production facility, greatly reducing emissions compared to facilities that use fossil fuels. This new aluminum sourcing policy limits emissions to 11 kg CO₂e per kg or less. For reference, the global average is 16.1 kg per kg, according to European Aluminum.

At present, it appears that Trek is focusing on low-emission aluminum and is also using recycled aluminum when possible. Of course, aluminum recycling is well developed, and post-consumer recycled materials can make a big impact in terms of emissions reduction, but the brand also recognizes the importance of understanding the source of recycled aluminum to account for its emissions properly. According to Trek, they are “following guidance from ISO 14021, ISO 14067, the Aluminum Stewardship Initiative, and the International Aluminum Institute on carbon accounting processes.”

As part of the new aluminum sourcing policy, Trek has reportedly worked with its suppliers to set expectations and make the necessary changes to meet this new, lower emission limit. In fact, Trek says it has “teamed up with the Dutch nonprofit Shift Cycling Culture, the German development agency GIZ, and other bike brands to develop training on the core concepts of sustainability, carbon accounting, regulatory guidance, and data analysis to help our suppliers identify the biggest impact areas in our operations.”

How’s it Going?

According to Trek, most of the aluminum it now sources falls well below the emission limit mentioned above, and it has effectively reshaped its supply chain to work toward its sustainability goals. The brand says the first low-impact aluminum frames came off the line in August of 2024. It started with a couple of its most popular bikes, the Trek Marlin Gen 3 and Domane AL, but is rolling it out on more of its aluminum models now, including the aforementioned Roscoe Gen 4 and the recently released Domane+ ALR.

Frame tubing is arguably the largest piece of the pie, but Trek plans to implement its low-emission aluminum in the construction of other components like rims, handlebars, seatposts, stems, and more. “We’re not done,” said Trek’s Global Sustainability Manager Joel DeMeritt. “Our aim is to apply this thinking across every major aluminum part we make.”

Using its most popular bike, the Marlin Gen 3, as an example, Trek estimates a total emission reduction of 53.7% once the majority of the aluminum parts have transitioned to low-impact aluminum. To be clear, so far it is primarily the frames that are in production, and the move to manufacture other components from low-emission aluminum is still a work in progress, but hopefully coming soon.

A Step In the Right Direction

While this certainly could and probably will be construed by some as greenwashing, virtue signaling, or patting themselves on the back, we appreciate that Trek is actively trying to improve its processes and reduce its emissions. It takes actual effort to move the needle, and the impact that a larger brand like Trek can have is significant in the bike industry. Moreover, Trek hopes that other brands join them in sourcing and using low-emission aluminum for frames and other parts.

Indeed, it would be more challenging for smaller brands in the industry to create a major shift in materials sourcing in the cycling industry. But perhaps once Trek has opened the door for lower-emission aluminum, it may become much easier for other brands to follow suit. “This is a major move, not just for Trek, but for what’s possible in bicycle manufacturing,” said Trek President John Burke. “It’ll put us years ahead of our climate goals, and it proves there’s a better path. We hope other companies will join us, inside and outside of the bicycle industry.”

According to Trek, it is happy to share its new sustainable aluminum policy, which is available on request and will be shared with any interested brands at industry events. “We recognize that lowering Trek’s emissions won’t save the world,” said Trek’s Joel DeMeritt. “That’s why we want to empower other businesses in the cycling industry and beyond to make and multiply change.”

To learn more about Trek’s low-emission aluminum and the rest of its sustainability initiatives, take a look at its most recent sustainability report. You can find the report and all of the latest aluminum bikes made with lower-impact aluminum, including the Roscoe Gen 4, Marlin Gen 3, and Domane AL, on the Trek website.