When sustainability-focused designer Satoshi Yanagisawa of Japanese firm Triple Bottom Line approached the production bicycle, he saw opportunity in material optimization and customization per user. The result of his efforts is the DFM01, a cleverly designed and weight-competitive (the concept is 15.4lb when built into a complete bike) carbon fiber and titanium frame that can be reconfigured and printed custom around each user through an evolving geometry algorithm.

Triple Bottom Line is currently testing the product to establish viability with the goal of making it available to the public. It will be on display at the London Design Festival this Fall, but you can take a sneak peek here…

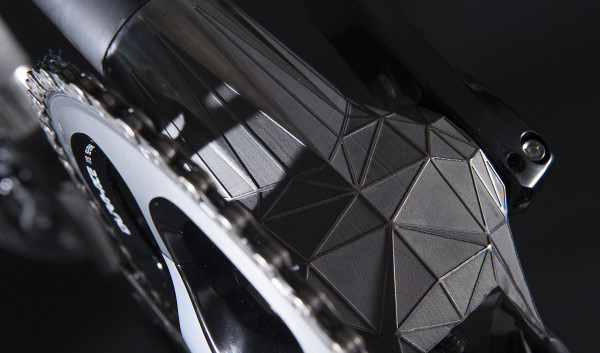

The carbon fiber component of the frame consists of simple round profile tubing. The titanium components, which comprise the bottom bracket/chainstay, seat cluster, and head tube junctions, are produced using an additive manufacturing process called selective laser sintering (SLS), which bonds powdered titanium together at high heat (but below its melting point). By nature of only using the material sintered into the final product, SLS is a low material waste process. So, by allowing for complex three-dimensional forms that are impossible in more typical manufacturing techniques, Yanagisawa is able to more sustainably produce a complex design that can be structurally optimized (via simulation) prior to fabrication and produced efficiently, without additional material removal processes.

But the really exciting capability of this process, according to Yanagizawa, is its ability to print custom structural elements to make each bike function its best with the user:

“This is a key factor of this frame. Basically, our geometry generating system, currently under development, allows us to create a perfectly optimized frame geometry from an individual user’s information (height, arm and leg length, flexibility, and so on). The system takes those numbers then creates optimised 3D geometry. Obviously, the majority of bike manufacturers are doing this phase – creating different frame geometries – by hand at the moment.”

At this time, there is no time frame or price scale available for the DFM01.