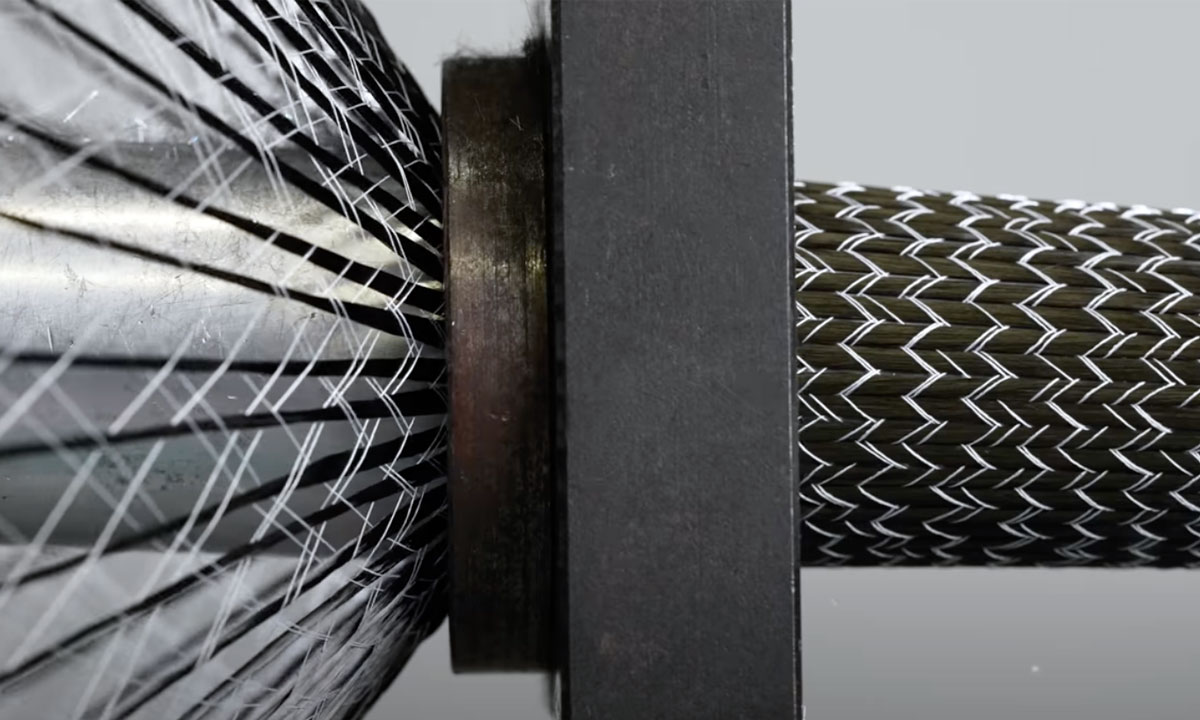

If you’ve seen any of our factory tour videos and posts, you’ve seen a lot of different ways that bike brands cut, layup, and mold tubes from sheets of pre-preg carbon fiber. TIME has always done it a little differently. OK, a LOT differently. Here’s a look at their radial braiding process that literally weaves the tubes in 3D…

Because they’re not using pre-preg carbon fiber sheets, which have the resin already impregnated into them, TIME uses a Resin Transfer Molding process. This means the resin is pumped into the molds after the braided dry fiber “socks” have been slid over the reusable wax mandrels.

It’s pumped in, then the pressure and heat increase, forcing the resin to fully saturate the fibers before the excess is pressed out. Throughout, the wax mandrels remain rigid, allowing the front triangle and other frame elements to be cured as a single piece. Afterward, they’re melted out, then the wax is reused to create a new one the next day.