A while back in the summer, I took a look inside the Zéfal factory to see how one of the oldest accessory manufacturers in the cycling industry still makes a majority of their products in France. In a time where basic biking items like water bottles, bottle cages, pumps, racks, fenders, rearview mirrors, and even chain lube are often made far away in Asia to keep costs low, family-run Zéfal manages to still make them all in Europe.

On the banks of France’s famous Loire River, made in the small town of Jargeau, and at competitively affordable prices.

So how do they do it?

Who is Zéfal again?

As a quick refresher… the company’s relatively young name is something of a portmanteau, a “combination of Zephyr, the personification of the wind in Greek mythology, and Duralumin, the aluminium alloy used in the manufacture of the first Zéfal pump in 1934.“

The company has only been known as Zéfal for less than 30 years, but they’ve been making cycling products for 140+ years.

Why you know many of their innovations without knowing the brand?

First off, a surprising thing about Zéfal is that, in one form or another, they have been developing and manufacturing cycling accessories in France since 1880. And I would go out on a limb to say that every cyclist who regularly reads this website knows, and often uses, at least one of their technological innovations.

Yet, at the same time, many of you won’t really know much about the brand – or even be familiar with their name.

Why is that?

You see, the company only became Zéfal in 1998, named after their most popular pump brand.

Before that, they operated under several other company names, most of which you wouldn’t know either, as separate companies bought each other out, and ultimately merged into one.

First Sclaverand & AFA, then Morin & Poutrait, and only Zéfal in more recent years.

But the products they developed are iconic.

Sclaverand invented the Presta valve. And Eugène Christophe created the iconic metal toe clip. Both around the turn of the 19th century. They each would join what would become Poutrait-Morin in a 1935 merger. And it would be more than half a century later – after frame pumps, floor pumps, and the world’s first telescopic MTB mini pump dominated their sales – that the modern Zéfal name would come to the forefront.

Now, 4 generations later, it’s still a family-run company. Two brothers descended from the Morin side of the business run Zéfal today, with all new products developed entirely in-house in Jargeau, in the Loire Valley.

Made in France mostly, often involving robots

The percentage has gone up and down over the years. But today, Zéfal makes 60% of their cycling accessories in France. That’s a surprisingly high figure considering how many of their products are genuinely affordable.

When you search their product catalog, those items made entirely in Jargeau get a very prominent Fabriqué en France logo with a little French flag icon. Like the Magnum Pro water bottle, that’s a favorite of ultradistance cyclists around the world for its high 975ml capacity that fits in standard cages. As well as a bunch of other products we saw being manufactured, first-hand.

Besides the products made in-house and clearly marked with a French tricolor in their catalog, others likely made with a mix of elements from outside French suppliers forgo the flag. But they still have a note indicating if they are made in France. Read the full product descriptions, and you will find a surprising range of products still made in France.

It isn’t 60% of the total items in their catalog, though.

Zéfal makes all of their modern mini-pumps, racks, bags, and lights, for example, overseas. But many high-volume items like water bottles, cages, fenders, lubricants, bar-mounted mirrors, and even a growing range of Zéfal floor pumps are entirely made in France.

Automated plastics manufacturing

The trick, it seems, is that wherever Zéfal was able to refine production with efficient industrial automation – and often manufacturing robots – they could manage to make those products in France, while keeping prices competitive.

A lot of that relies on efficient plastic molding – with various materials and colors depending on the task at hand.

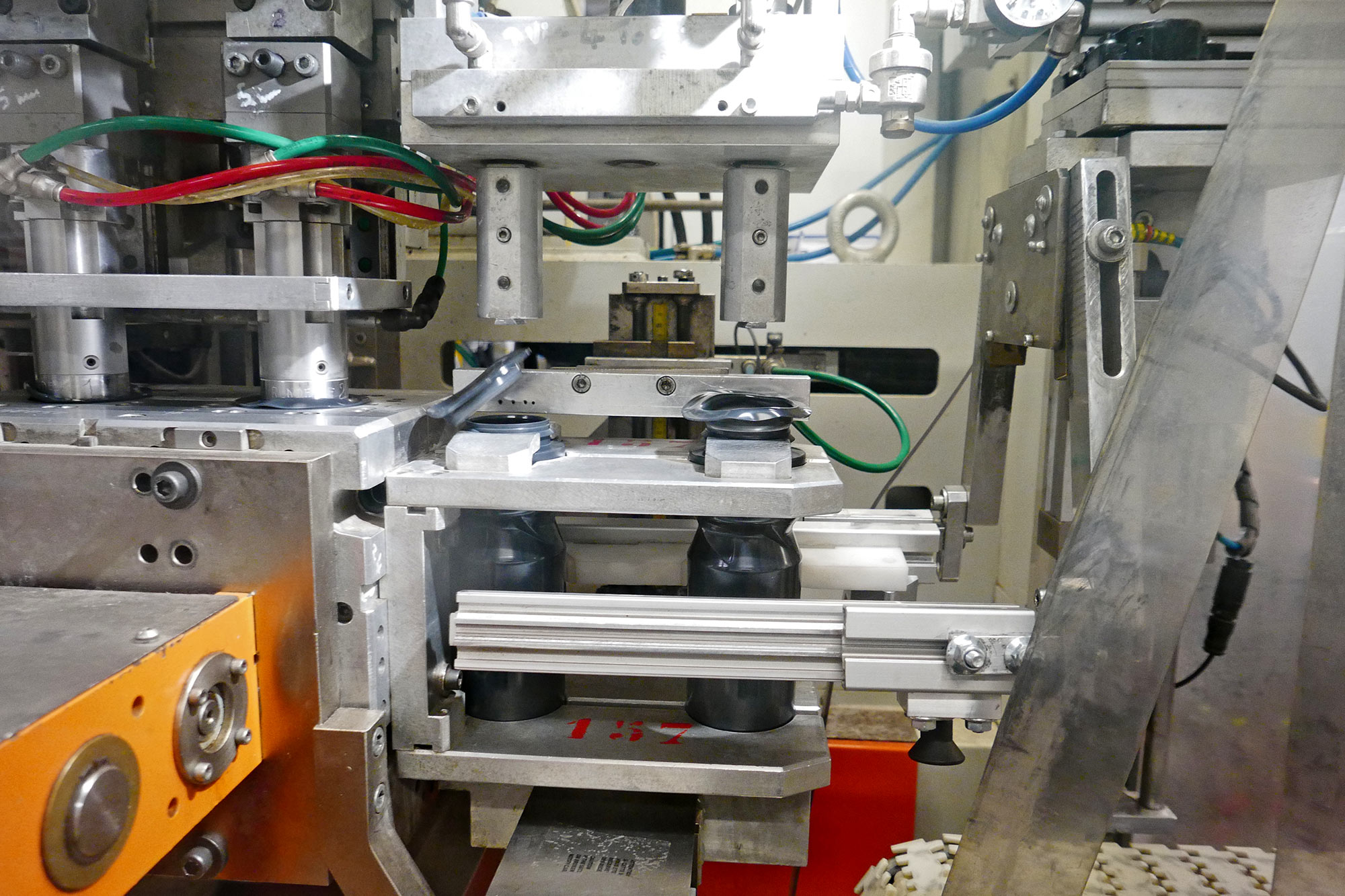

Whether blow molding bottles or injection molding caps – what I saw inside their factory was a complex maze of material management.

Rows of plastic pellet dryers, raw material vats, and intertwined hoses – all to get all that plastic raw material to the right machines crisscrossing across the factory floor.

So, what products did Zéfal show Bikerumor being manufactured?

Inside the Zéfal Factory in Jargeau, France

French water bottles

A core product for Zéfal is their range of standard Sense water bottles. Selling for anywhere between 5-11€, they come in four different sizes, a couple of different materials, and a couple of different caps.

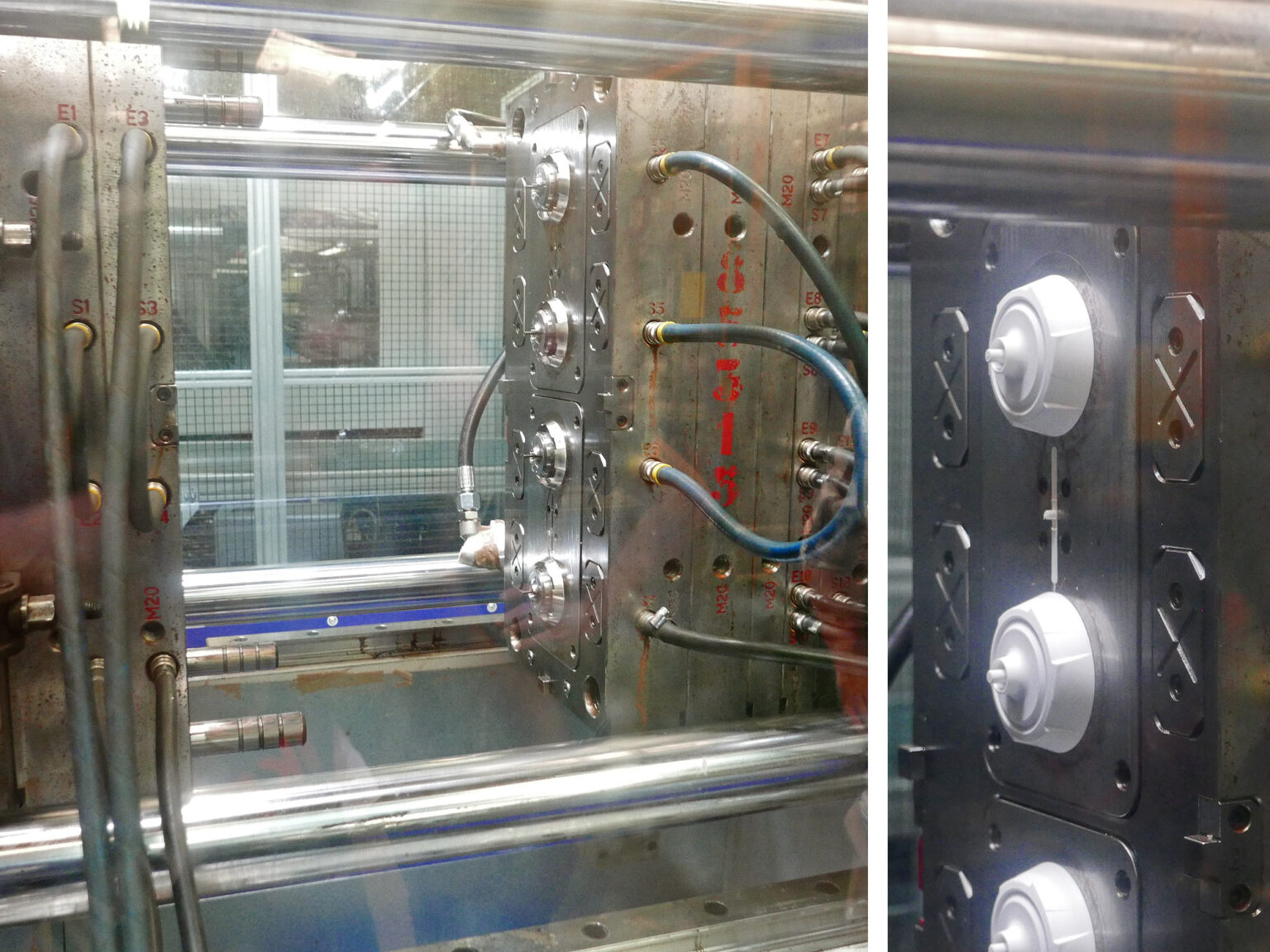

But pretty much all of them are made in the same, mostly automated processes. Bottles are continuously blow-molded from an extruded plastic tube, while their caps & valves are injection molded, and then assembled with a semi-automated tool.

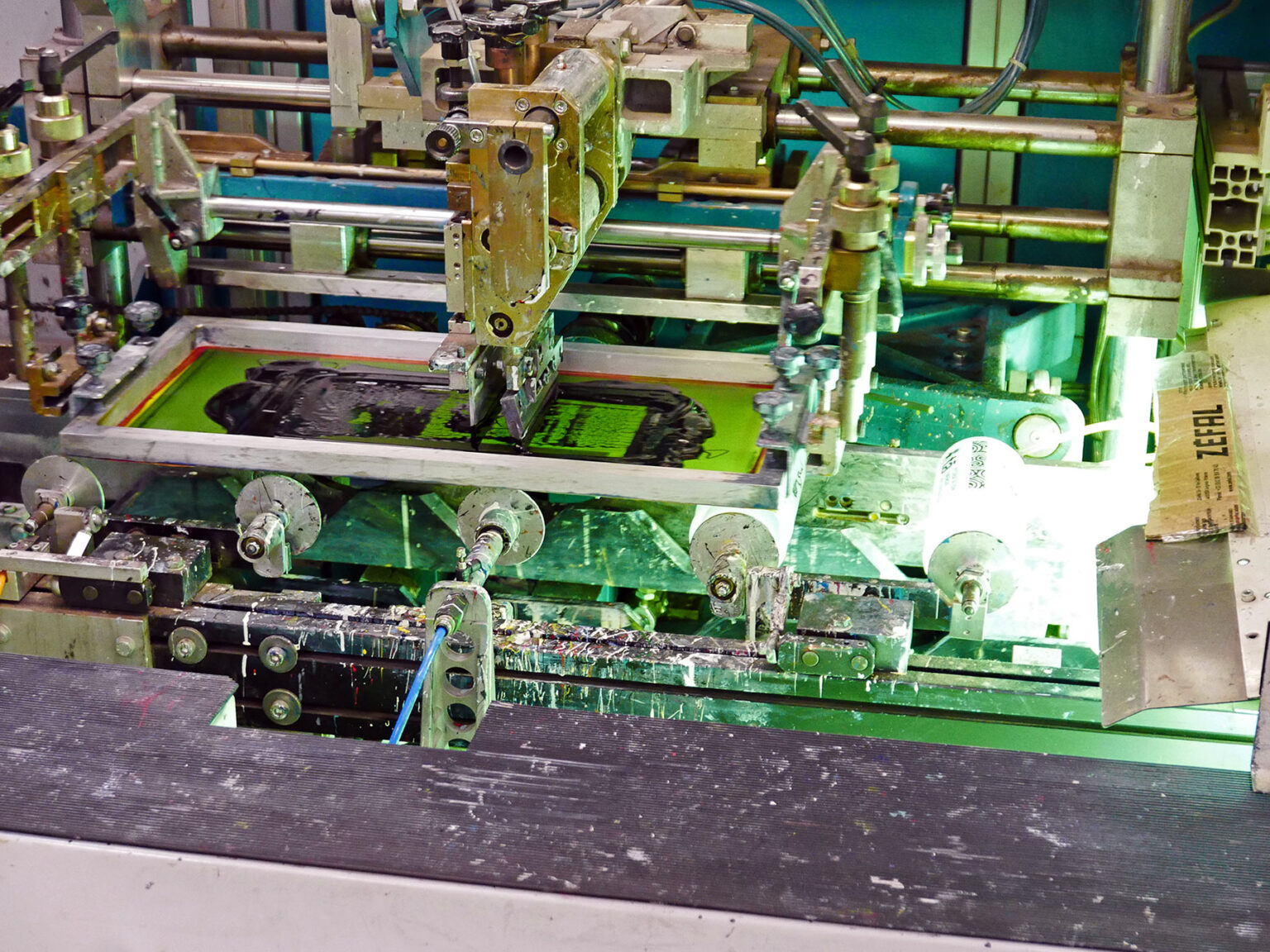

In addition to stock bottles, Zéfal also produces huge quantities of custom bottles. The blanks follow the same manufacturing process. Then, Zéfal applies logos with an automated machine that silk-screens them as the roll by, down the production line.

Zéfal manufactures a full range of insulated Arctica bottles in the factory, too.

They share the same automated manufacturing for the inner bottle, outer shell, and cap. But the rest is a much more manual affair. Factory workers wrap the insulation over each bottle by hand and manually press on the outer plastic shell, one at a time.

And yet, the Zéfal Arctica bottles are still similarly affordable – ranging from 10-15€

Low-cost French bottle cages

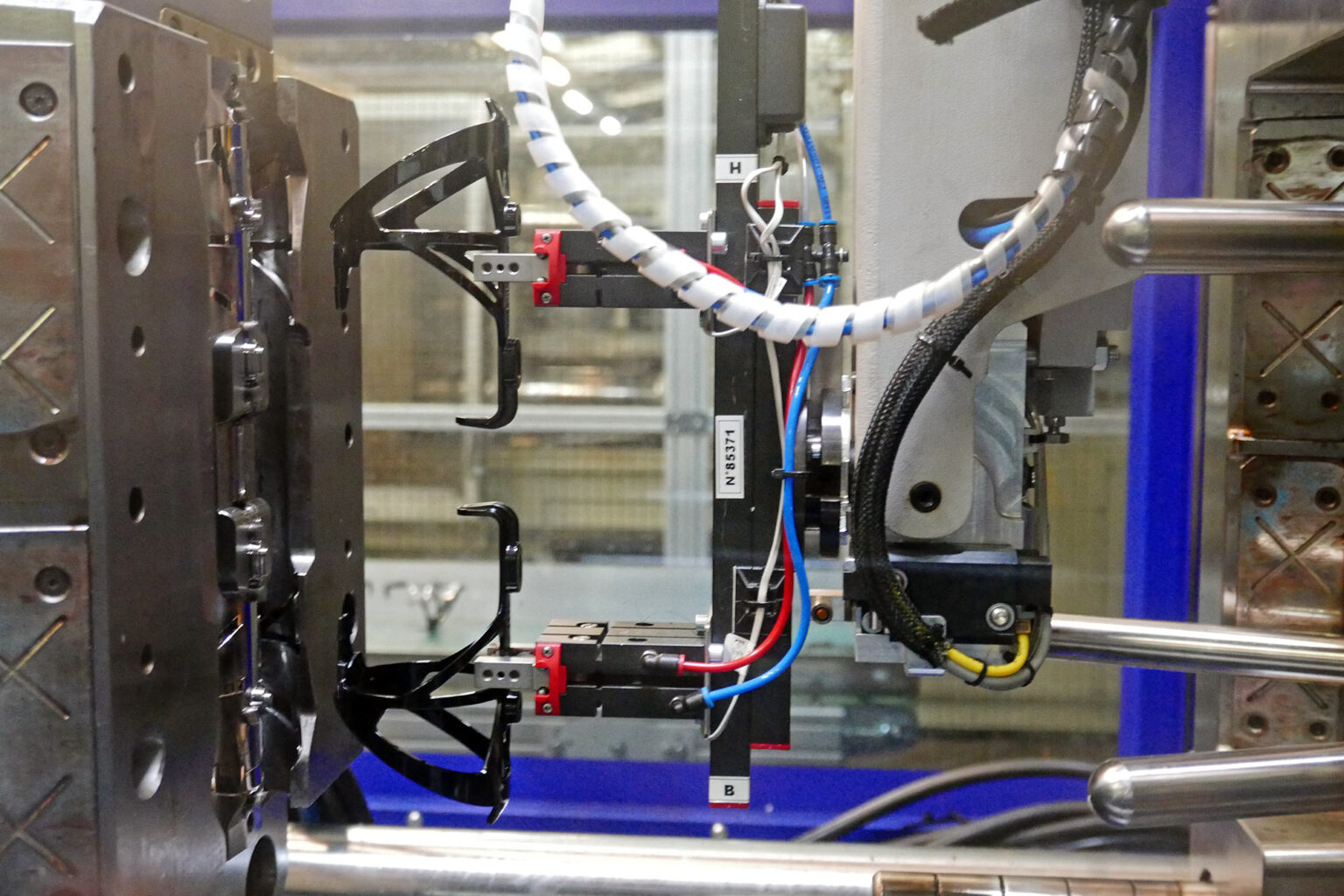

Next up are a bunch of French-made, injection-molded bottle cages – mostly from simple plastics or fiber-reinforced composite materials. Again, they are refreshingly affordable for an EU-made product.

That first pair of Pulse A2 cages coming out of the mold together are just 9€ each and only 26g. The sideloading Pulse Z2 in my hand is just 13€ and 40g.

And that third cage – getting its painted graphics stamped on and then flame broiled (cured) before being packaged for sale – is the 4€ Spring, a thermoplastic polyamide resin cage that weighs just 46g. Bottle cages that affordable are rare, no matter where they are made.

Except… oh yeah, there’s another 4€ cage made in Europe. It’s this Zéfal Alu Plast 124 – an ultra-low-cost combination of machine-bent aluminum and a pressed-on plastic bracket that weighs just 40g and comes in 7 color options.

French bicycle safety mirrors

Zéfal’s handlebar-mounted rearview mirrors are another huge seller. Almost all of these are entirely made in France, using various plastic brackets for different types of city bike applications. And precise robot injection molded mirrors that get a special chrome-like reflective coating applied to see what’s coming up behind you without optical distortion.

I would not have imagined there was so much demand. But Zéfal makes more than ten different safety mirrors for cyclists, ranging from 12-40€.

French cycling lubricants

Zéfal also sells a range of cycling lubricants – 4 types of chain lube, plus grease and assembly pastes – for 6-10€ per bottle.

The lubricants themselves appear to be mixed off-site by a local chemical supplier. But it all gets loaded into vats, bottled, and labelled on an automated production line in the same Zéfal factory that makes the rest of their cycling accessory lineup.

Not only high-volume items made in France

Since 2017, Zéfal has been onshoring pump production back to France. I suspect that they don’t sell as many high-end floor pumps as their low-cost floor pumps and imported mini-pumps.

But, what started as just one French-made Profil Max FP60 pump model grew into 4 versions, ranging from 60-75€ – all made entirely in France, and featuring French hardwood handles

Plus, there’s still a lot of historical Zéfal production going on. When I was visiting, they had spun up an old machine to make a batch of woven fabric air hoses – something that only happens every now and then – but make up part of a super cheap 4€ inflator kit to use any bike pump to inflate balls or mattresses.

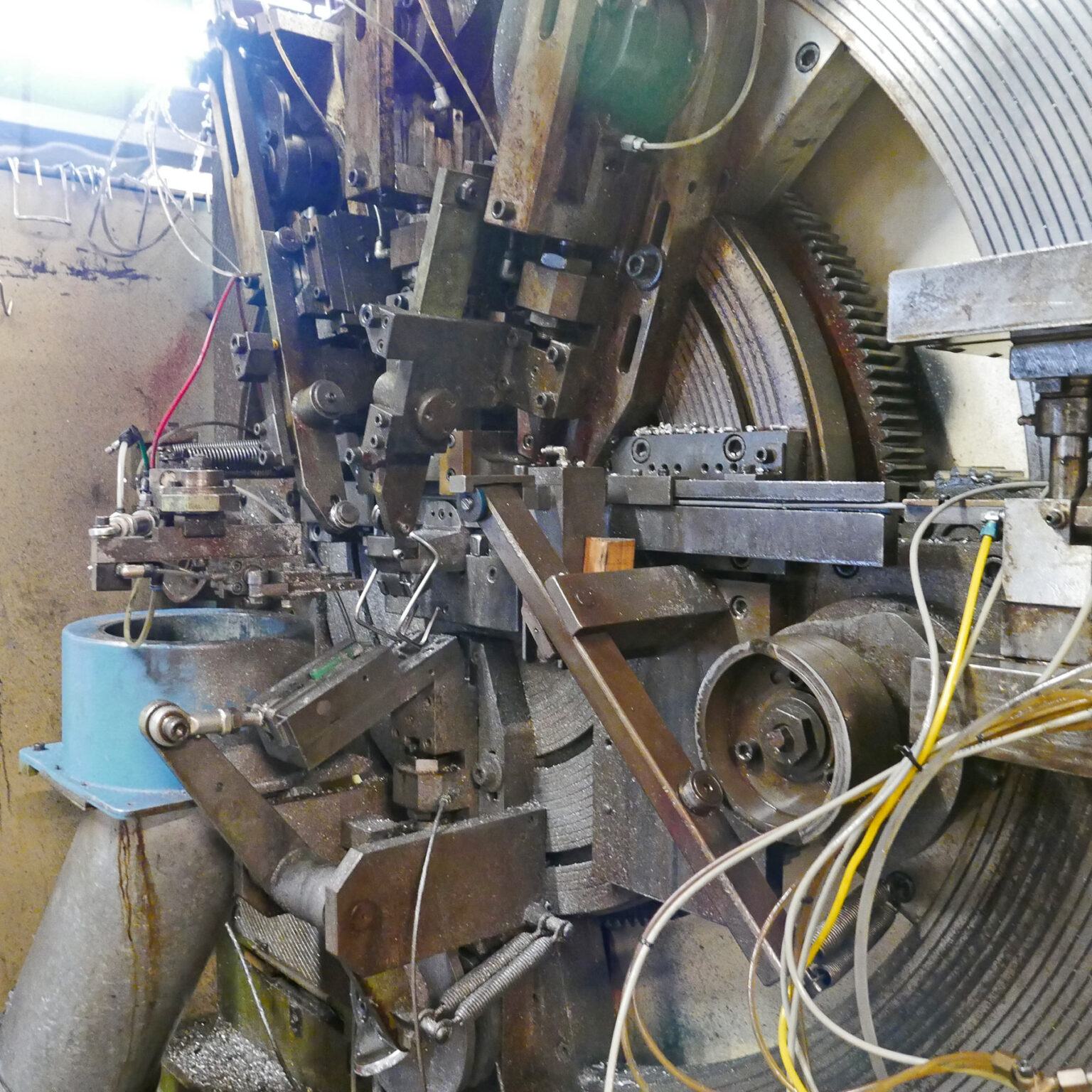

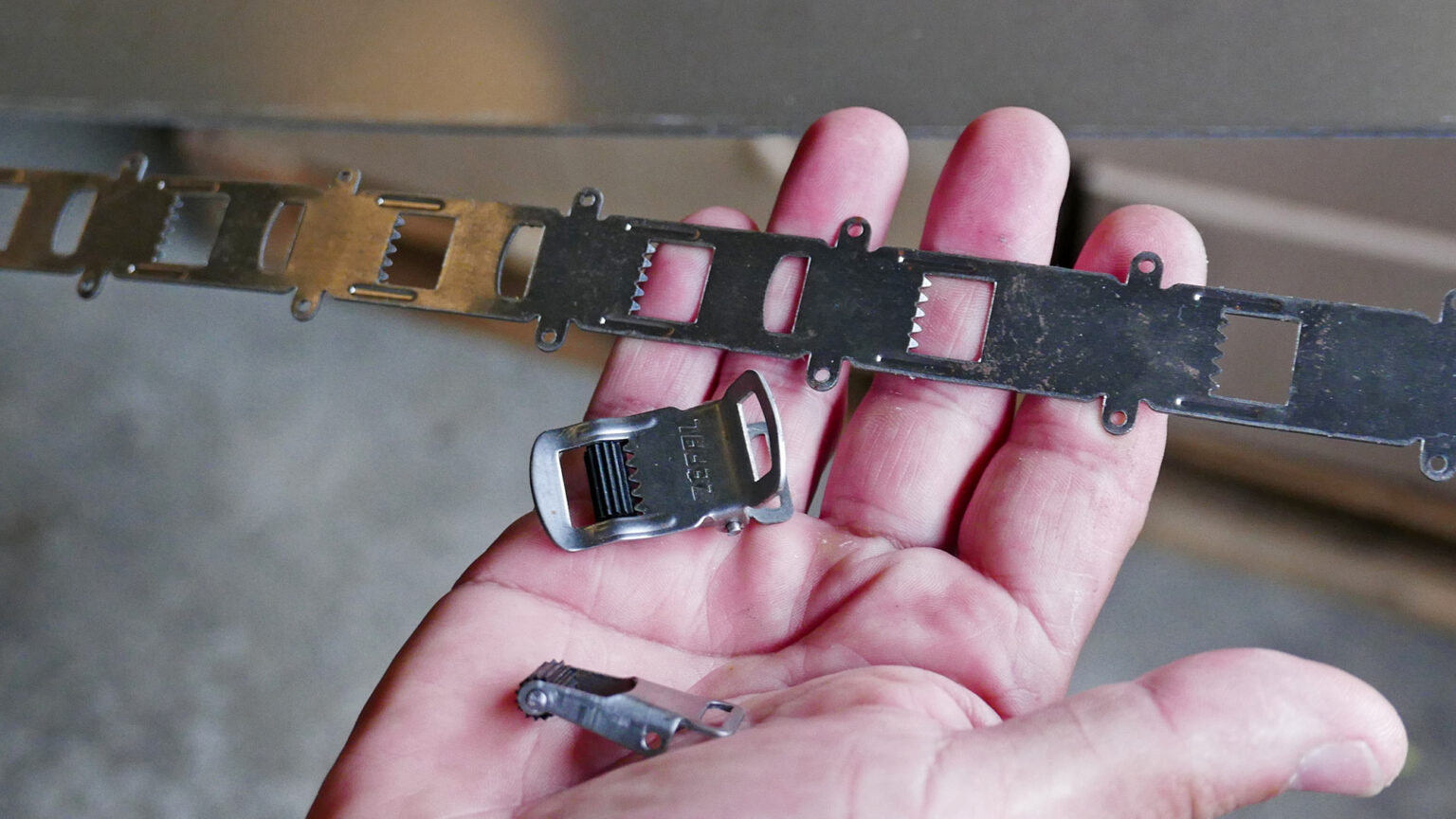

It also looks like those original Christophe toe clips are still going strong.

Zéfal still stamps them out of a plate of steel in several steps, before bending & riveting them into their final shape. And they even manufacture the steel toe strap buckles in-house, before giving them woven nylon or leather straps to finish off a classic cycling accessory.