Look around and you might notice that more and more bikes are using the BB86 and BB92 bottom bracket shell. That’s a boon for Shimano since they’ve resisted going to a 30mm spindle, and it makes using that larger spindle that SRAM, FSA and others love more difficult to use.

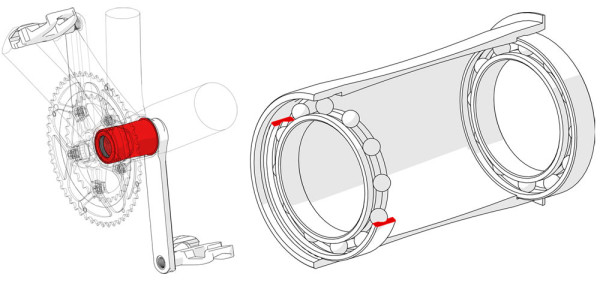

BBinfinite founder Wes Wolfenbarger noticed that trend and saw another issue – bearing placement. Fortunately for him, his one-piece design solved that issue if you were running a straight 24mm spindle. But if you had a GXP crankset, which steps down to 22mm on the non-drive side, you’d have to stick with a traditional two-piece, pressfit bottom bracket. And that simply wouldn’t do.

So, not only did Wes create a complete line of GXP BB’s, increasing his SKU count by a full third, he wrote one heck of a story about how bottom bracket shells, bearings and spindles work together. Or don’t…

BBinfinite’s design philosophy is simple: Take the frame out of the equation. Frames, particularly carbon fiber ones, can have varying tolerances that don’t always line the bearings up perfectly. That puts a torsional load on the spindle, which creates drag. That’s the first problem.

The second is the cheap composite cups that the bearings sit in. These cups are pressed into a frame that may be too tight, which ends up putting radial pressure on the bearings. Drag and reduced lifespan are the result.

Their one-piece BB shell solves both problems. It provides a stiff, perfectly aligned platform for the bearings to rest in, and the firm metal shell won’t allow radial deformation of the bearings.

With those two issues solved, the final piece of the puzzle in reducing drag was to eliminate pressure coming from the crank arm’s installation. To remove lateral play from the spindle, we typically use a wave washer or tighten the bolt inside the spindle to pull both arms snugly against the BB. This can load the inner bearing race, causing it to shift out of radial alignment with the outer race. Once again, drag and reduced lifespan are the result. BBinfinite’s solution is a solid sleeve supporting the inner races, keeping them perfectly aligned with the outer races so the bearings roll as smooth as can be. Video above shows how it works.

That was great news for anyone with a BB30 frame or, as long as you were running Shimano or FSA MegaExo 24mm spindle cranks, a BB86/92 frame. If you had GXP cranks, BBinfinite couldn’t help. Until now. Over the next eight weeks, they’ll roll out GXP compatible BB’s for:

- BB30A Campagnolo

- BB30A Shimano

- BB30A GXP

- BB30 GXP

- BB386EVO GXP

- BB86 GXP

- PRESSFIT 30 GXP

- BBRIGHT GXP

- OSBB GXP

- OSBB MTB GXP

- PRESSFIT 30 MTB GXP

- BB92 MTB GXP

- BB30 MTB Shimano

- BB30 MTB GXP

They do offer a bottom bracket that’ll fit a 30mm spindle into a BB86 frame, but Wes says the bearings have to be so small that they’re easier to damage when inserting or removing the cranks, particularly FSA cranks whose spindles tend to be slightly larger in diameter than normal.

Each model is made specifically for each application, which includes the particular frame type as well as the particular crank spindle, so there are no adapters or spacers needed other than an occasional wave washer. That said, what separates the GXP models from the 24mm ID models is the use of an alloy reducer on the non-drive side. This keeps the bearing as large as possible while stepping down the inside diameter to GXP’s 22mm spec. The side benefit of this is it serves as a stop for the spindle’s step, which is sized such that the spindle will pull perfectly snug against it so there’s no lateral play.

The drive side uses a Shimano-style top hat so there’s no steel on steel (spindle on bearing), helping everything last a good long time.

Whether you’re running GXP or not, Wes says their design allows for the most freedom of crank fitment since there’s no flange on the driveside. That makes more room for power meters and ensures the driveside stays well within the chainline guidelines for optimum shifting.

Look for all of the GXP models to be shipping in early 2016, before the road racing season starts. Check out their tech page for a graphical illustration of all the ways two-piece PFBB’s suck (starts about 1/4 of the way down the page).