Following the recent announcement if their new 27.5″ fork, Lauf has revised their already really light short travel leaf spring 29er fork to be a bit lighter and a bit stronger.

The revised lower section around the axle is cleaner looking, and it now holds their own bolt-in thru axle rather than being spec’d with the Rockshox Maxle. It’s just 47g, a considerable drop, and ther are new molded axle guides that the wheel can rest on while being installed.

More weight savings come from the full carbon bump stop, which replaces the alloy one on the original. You’re only goin to hit it when you bottom out the 60mm of travel, which is harder than you’d think.

Inside the legs, the leafs get a steel pin holding them in, adding a mechanical fastener to the existing bonding for a little insurance. They weren’t having many issues, but it was an easy addition since they were reworking it anyway.

All in all it’s about 40-50 grams lighter than the original, putting most production units around 960-970 grams. Even better, most of the weight savings are unsprung mass.

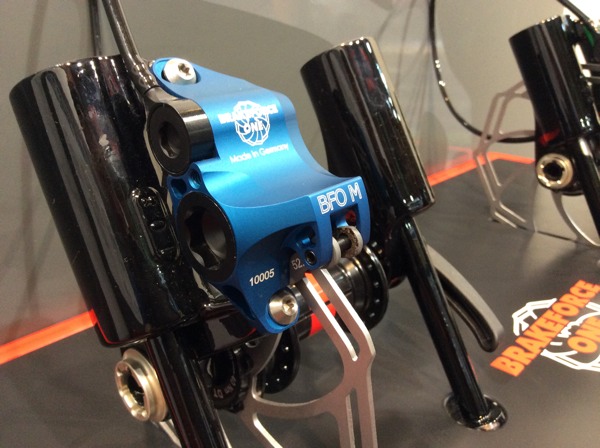

BRAKE FORCE ONE

Brake Force One, who uses a completely closed system for their hydraulic disc brake that we’ve detailed here, has a new BFO M caliper with a magnet instead of a spring to pull the fluid’s port piston back to the closed position.

Compared to the original with the spring, they say it reduces the effort needed to pull the brake lever by about 30%.

The entire front brake is about 175g, of which the lever is only about 36g.

They also have new rotors that require less break in time to get them up to full friction and braking power, particularly with their own resin pads. The rotors are stainless steel, they’re just not polished to a shine. Instead they’re bead blasted to harden the surface and give it a bit of roughness.

New green, red, black and blue colors available as standard, plus tons of special edition colors available on a random rotating basis.

SCHLUMPF ADVANCED BELT DRIVE

Schlumpf is a Swiss company that makes internally planetary geared cranksets. They’ve also made belt drive systems, and the new one uses a one piece sprocket and chainring that’s much lighter. Previously two piece cogs that had to be sandwiched over the belt and bolted together were the norm.

The belt uses 14mm tooth spacing and taller teeth so they can run it under lower tension than competing belt drives.