By way of Siberia, Sarma continues to push the envelope for fat and mid-fat products. One of the first carbon 29+ rims, the Naran 29+ is double-walled, 50mm wide, and made for the big beastly traction of a 29″x3″ tire.

Zach saw them at Interbike, and now we have a set for testing. There are very few 29+ specific bikes on the market, so many riders are resorting to running the tires in a fat bike frame, since they fit in most. Doing exactly this, our test wheels are built to Sarma’s fat bike hubs, and we will be testing them on the Shaman fat bike we have on long-term test.

Click past the jump for our first thoughts on their construction, as well as actual weights…

The wheels arrived really well packaged, handbuilt by Velocity in Michigan, and with each one signed by the wheelbuilder. This makes sense since Sarma’s US distribution is based in Michigan. As of right now, the wheels are not offered for sale complete, since there are a wide variety of hubs and fitments out there that they could be used on.

I had a set of the first generation Naran 80mm, and the graphics of the new products, as well as the matte black finish are a step above what they started out with. Sarma is growing fast, but also listening to what consumers want. Sarma also says their engineers have deep backgrounds in aerospace composites, and use Finite Element software in the design of the rims to design the proper shape and fiber orientation.

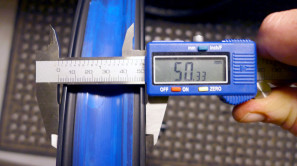

The rim widths measured out exactly as claimed, at 50.33mm on the outside (with the 0.33 probably accounting for finish), and 44.17mm inside.

The wheels were sent to us complete, so we were not able to measure the rim alone against the 550g claim, although based on the complete wheel weights, it is probably very accurate. These weights are with Sarma 135/170mm hubs and Sapim butted spokes, with tape and valves installed.

One very impressive thing about the rims is that they came with the best internal finish I have seen on a rim. That’s pretty impressive since my go-to wheels are ENVE AMs, and I have ridden many other carbon wheels. These are literally the smoothest, most consistent finish I have seen to an inner rim wall on any carbon rim. This says a lot about manufacturing capability, as molding a hooked-bead rim is not an easy feat. Sarma says that most other companies use a silicone mold in this area, and then finish the rim by sanding, which cuts the fibers. More important to them than the finish, they wanted uncut fibers throughout to retain strength. They do not say what they use to achieve this, probably because it is so impressive, they should keep it as a trade secret.

- Width: 50mm

- Weight: 550g

- Drilling: Centered (32 holes, spoke holes offset ± 7 mm)

- Compatible with tubeless

- Drilled for Presta valve.

- ERD: 592.5 mm

- ERTRO: 622 mm

- MAX Rim pressure 25 psi

- Max Recomenden spoke tension 120 kgf.

- Recommended valve’s length: 45 mm

- Recommended width of tubeless tape 30 mm

- Recommended spoke’s nipple: 12-14 mm x 2.0 mm