BBinfinite debuted last May with a unique, one-piece pressfit bottom bracket design intended to remedy any intolerances in your frame, ensuring smooth, quiet cranks. Shortly thereafter, we received a test unit and combined it with our SRAM CX1 build and it’s been smooth sailing ever since.

The BBinfinite bottom bracket sets itself apart by putting both bearings in a single shell, allowing them to control the placement of each in relation to the other without regard for any differences in frame design. As they told us, even an offset as small as 1/1000th of an inch can cause drag and premature bearing wear. From our own experiences, we believe them. With their system, you have perfect alignment between the bearings. You also end up with a much broader contact patch between the shell and the frame, which eliminates play and, thus, creaking.

That’s the promise, here’s how it held up…

The parts consist of the shell with bearings and two covers, weighing in at 117g for a PFBB30 model for 30mm spindle cranks.

Because everything’s put together as a fixed system, you need to order a unit that’s specific for the type of frame and crankset it’s going to marry. They even have Campy versions to accommodate the pre-installed bearings that come on Campagnolo cranksets…but even those BB’s come with bearings just in case you want to switch the stock Campy ones out. That eliminates spacers, reduces and other contrivances that can introduce problems.

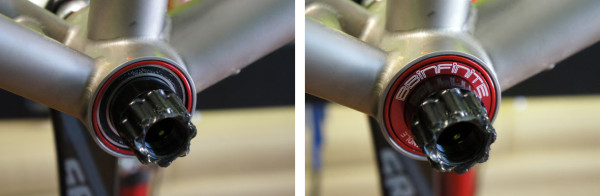

The shell has a lip on one side, which is pressed into the non-drive side of the bike. A cylinder inside prevents outward (preload) pressure from installing the cranks to affect the bearings.

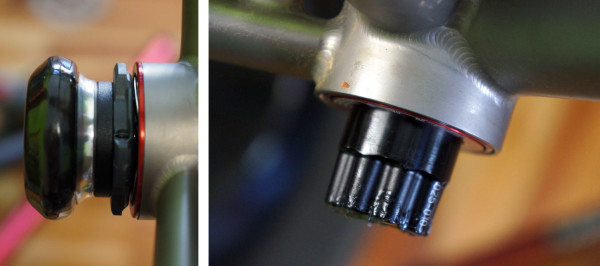

The “Top Hat” covers use a labyrinth seal system to keep water out, and a bushing sits between them and the bearings. This provides a smoother contact surface between parts and eliminates metal-on-metal contact that could cause squeaking.

The drive side has no lip, which is why it can press through the frame as a single piece. The slight indent on the middle of the shell should allow for Di2 wires to slip past even in the tightest BB shells, but something to think about, particularly on metal frames.

It comes with installation cups, which fit on either side of the frame like so:

You’ll need a headset press or similar to actually press it into the frame. Not shown in this pic, they provide a small amount of light-duty thread lock to brush onto the non-drive side of the BB and inside the frame on the drive side. Once it’s all in place, it pushed in easily.

Then just place the caps…

…and you’re ready to install the crankset.

It’s a very flush fit and looks super clean, especially on the drive side.

SRAM’s cranksets use a plastic preload adjuster to take up any play, and I’m happy to report it doesn’t interfere with the BB’s shell. I’ve had issues with it rubbing slightly on another aftermarket BB, but it’s all clear for this model.

Now, it’s off the to races!

And the races were wet! And muddy! And sent grass clippings flying everywhere!

Yes, we had a somewhat wet cyclocross season here, and plenty of wet training rides. But even after six months of riding in temps ranging from below freezing to pleasantly warm, wet and nasty to dry and dusty, the BBinfinite is still rolling extremely smoothly. I decoupled the chain from the crankset just to check, and the cranks spin almost as freely as a wheel, which is a huge compliment and something I’ve never experienced with a standard BB.

So far, my testing has been with a Moots Psychlo-X RSL frame, which likely has pretty good tolerances in it’s BB shell. So, as a followup, the next time we’re building up a carbon bike from scratch, we’ll try to test another BBinfinite (or swap this one in if it’s the right fit) to see how it handles that type of frame. On my Moots, it replaced a Chris King PFBB30, which is super nice and had no issues whatsoever after more than a year of use, but the BBinfinite is simply the best I’ve tried.

Retail is $165. An extraction tool is available separately for removing the BB from your frame.