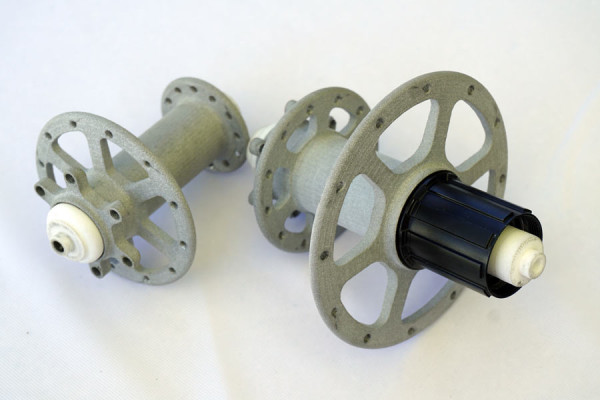

We covered Alto Velo’s ultra smooth hub design back in January, and since then they’ve been running full speed with their uniquely oversized flange rear hub to create stiff, efficient road bike wheels. When we spoke to them for the original story, they teased disc brake hub development, and now they’re almost ready. In fact, they’re shooting for an ambitious November timeline.

Not sure what that massive driveside flange is all about or why Alto Velo’s wheels are probably the smoothest we’ve felt? Roll on in for details…

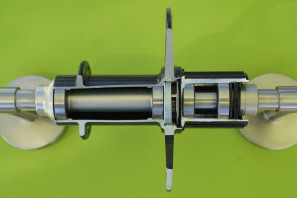

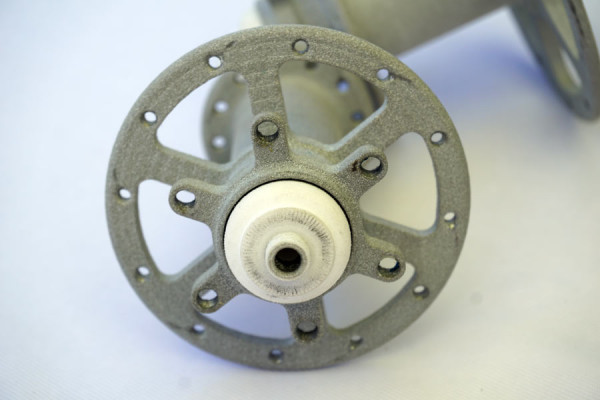

Alto Velo’s idea is simple: Move the driveside spoke placement outward from the hub’s center of rotation to increase spoke triangulation and create a stiffer wheel. But that only addresses lateral stiffness on one plane. To fix the problem from stem to stern, they looked at how the axles, bearings and hub shell interfaced and made improvements in tolerances, preload assemblies, axle construction and more. The launch story is a good read if the mechanics of hub construction interest you, but suffice to say they’ve eliminated virtually any chance for anything to wobble, lean, tilt or otherwise introduce slop to the system.

Part of their solution is by integrating one end cap onto the axle itself. That does mean you’ll need to swap the entire axle if you want to switch between QR and thru axle dropouts, but it’s an easy swap.

To create the disc brake hubs, the non-driveside flange had to move inward to clear the brake caliper, so they used the same philosophy as on the rear and gave that flange a larger diameter. That kept the tension from side to side at a similar ratio as their standard road hubs. The front hub got the same treatment but with a larger flange.

The disc brake hub axles are also one piece with the drive side end cap. Not only does it help make everything stiffer and stronger with fewer pieces, it helps maintain the tight concentricity and tolerances that make their hubs so smooth. They’ll offer axles for 12×142 and 135QR rear, and 100mm QR and 15mm thru axle fronts.

The bearings are the same in the disc brake versions, but they’ll offer two sets of seals – a standard set for road and a heavy duty set for cyclocross. Those heavy duty seals will also be used on a future mountain bike hub set.

The original rim brake road rims (shown here) were laid up to their specifications, with the carbon plies optimized for the spoke angles that their hubs created. Like with the standard wheels, they’d prefer to sell you a complete disc brake wheelset so that they control the build process from start to finish and ensure you’re getting the best possible system performance. The disc rims will be laid up differently (and come in a bit lighter!) since they don’t need to handle braking forces coming from the rim calipers.

Target launch in November, and they’ll be available as standalone hubs if purchased through an authorized wheel builder that’s approved to build them to Alto Velo’s spec.

Tubular and clincher will be offered.

While we patiently wait for a disc brake wheelset to test out, we did give them a spin at their tent and they are indeed remarkably smooth. As in, some of the smoothest wheels I’ve spun in recent memory. And it’s all done with NSK stainless steel bearings, no ceramics. Sometimes, when things roll so smooth, there’s a bit of play at the axle, but there’s absolutely none here.