An idea has been floating around some of the smaller industry players for about a year now. Brands like White Industries, Chris King and Paragon Machine Works were all thinking that people liked threaded bottom brackets, but that frames and cranks had changed so much over the past decade, getting larger diameter tubes that didn’t go as well with the tiny English threaded BB. These ideas progressed in distinct conversations running their own courses until one company contacted another to make a bottom bracket, and then everything really fell into place to (hopefully) replace the pressfit bottom bracket.

The driving force was to take the advantages of a 30mm spindle and modern frames and combine them with the proven durability, quiet performance and lovability of the traditional threaded bottom bracket.

The result is a new standard called T47, for “Threaded 47”. It measures M47x1, meaning a 47mm outside-thread diameter with a 1mm thread pitch (25.4 tpi equivalent). That puts it very close to the 24 tpi (threads per inch) currently used on English threaded bottom brackets, so it’s essentially been proven on bicycles for many, many years. And that slightly finer thread pitch helps to manually hand tap and chase the threads, a handy feature for frame builders.

To work, it needs a 46mm diameter bottom bracket hole on your frame, which happens to be the same exact measurement of a PF30 BB shell. That’s not a coincidence. White Industries pushed hard to make it a universal and backward compatible design.

“You could literally take a metal PF30 frame and tap it, creating a frame for a threaded bottom bracket. Pretty cool, right?” says Drew Guldaliun, owner and builder of Engin Cycles.

Conversely, any frame built around this new standard can also use existing thread-together aftermarket bottom brackets from Wheels Manufacturing, Praxis and Enduro (shown above).

T47 BB’s will work for both 30mm and 24mm spindles, using just four different cups and six different width shells to cover internal and external setups on virtually any frame.

Alec White, of White Industries, was one of the originators of the idea and told us “this has the potential to become the one single standard for the entire industry. It makes that much sense.”

It’s an open standard, meaning any and all frame and component manufacturers can use it at no charge and without any licensing. For frames, Argonaut Cycles and Engin Cycles helped bring this new standard to market, and both will have bikes ready to roll very soon. White Industries and PMW will have taps available for frame builders to make frames for the new standard, and those parts will be shipping in time for builders to prep NAHBS bikes for February 2016.

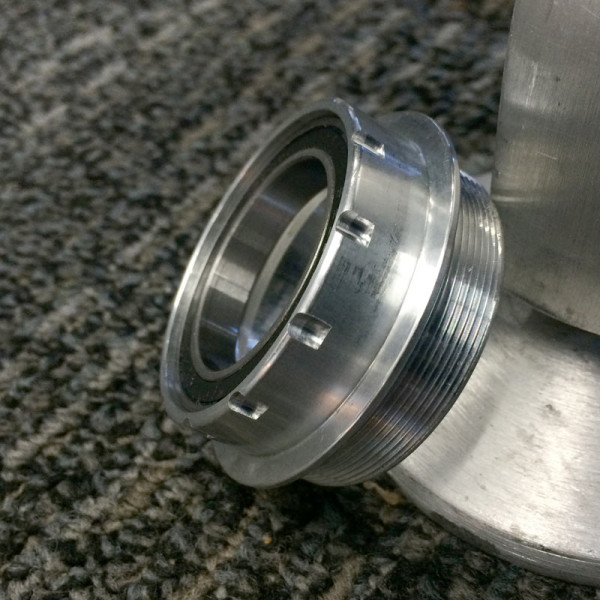

The video above and this image of Chris King’s new ThreadFit 30i BB are showing prototype bits. Production models will use a TorqTite tool to engage notches on the outside of the BB shell, like what’s shown on the Enduro parts earlier in the post.

These are the first production-level T47 bottom bracket bits from White Industries. They say some brands could also end up using the Race Face tool. Regardless of which install tool, the companies that helped make this happen wanted everything to work with existing tools and standards as much as possible, hence the compatibility with existing install equipment.

Everything old is new again. Thank goodness.

Look for hands-on pics of new parts from several of these brands this weekend live from the Philly Bike Expo!