Last summer, when they launched their all-new hubs and carbon tubular wheels, Mavic started down the road of new, wider Ksyrium and Cosmic clinchers. At the time, though, the prototypes were headed toward an alloy rim bed insert. That design had been their go-to for years, allowing them the look of a full carbon rim but with the security of an alloy bead hook and bed to better resist tire pressure and heat buildup. And, we rode it and it was headed for production.

But, thanks to recent hires and advancing resin technology, they were able to switch gears and develop their first full carbon rims. So, not only are they getting wider, but they’re using an entirely new construction method that builds the bead hook and rim bed as a single piece…with NO need to machine the hook. Fibers remain intact, new resins give them the requisite heat tolerance and a laser machining finish provides amazing stopping power.

As Mavic’s president Bernard Millaud explained at the start of our presentation, “You will now see the second phase of Mavic’s carbon development…”

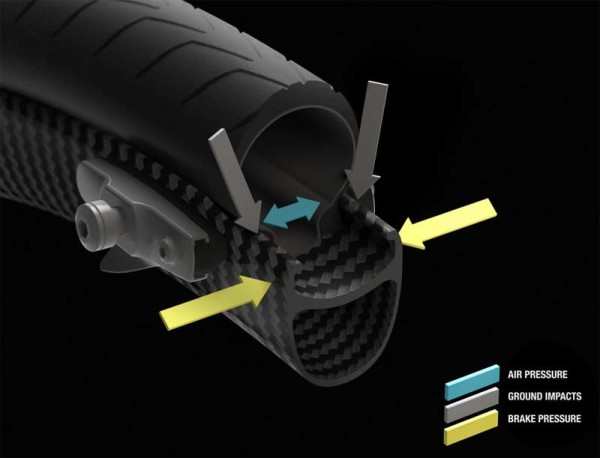

What does a good carbon clincher need? For Mavic, the answers are the ability to handle the mixed stresses of the tire’s air pressure pushing out, brake pads pushing in and ground impacts pushing down.

Technically, they say carbon is really good at handling pressures in one direction at a time, so getting it to handle all three is a challenge. Then, you add a fourth: temperature. Braking quickly builds up an excessive amount of heat, up to 200ºC (392ºF). They say most resins have a Tg (melting temperature) well below that number.

They serviced about 100 wheels during the 2015 Etape de Tour (a ~140km fondo), with 52 of them being failures and 38 were carbon clinchers that had delaminated or otherwise destroyed themselves.

The rims also have to meet safety standards, which is more than just impact testing. It’s also how the tire fits into the bead hooks and rests on the sidewall, and that is the larger challenge. Molding the proper curves and bead hooks are very difficult, which is why nearly every rim manufacturer overbuilds the sidewall then machines away the inside to create a bead hook. The problem with this method is that it breaks the fibers and creates potential weak spots. This is why Mavic has thus far used alloy inserts inside the channel, avoiding the need to machine the fibers. Those designs also helped dissipate heat, but it wasn’t without its own challenges.

Bonding the alloy rim bed into place was the original plan, but they were getting too many rejects off the production line. The process was just too difficult, and when they wanted to start making wheels in different widths and shapes, it was easier to just do it in full carbon.

All of those challenges went into a development wish list. The result? Carbon Clincher 2.0, in which they’ve found a better way to manage the heat and create the perfect bead channel shape straight out of the mold.

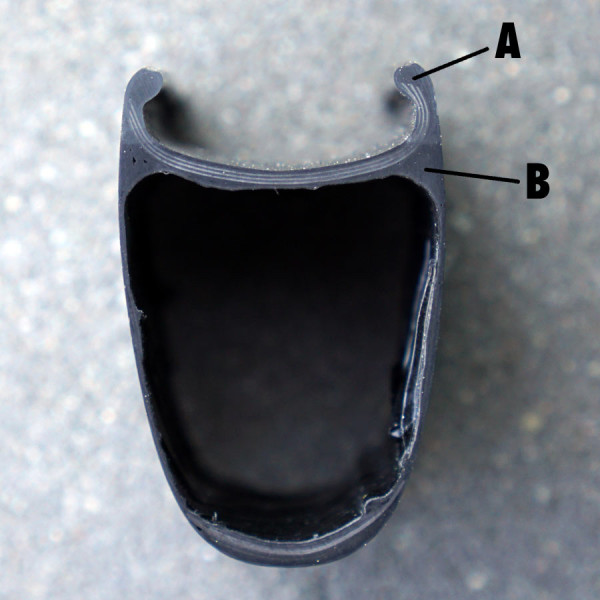

The rim bed’s shape is made from multiple layers to create a one-piece contoured section. The lower body of the rim is laid up separately, then the two pieces are molded together. The rim is full carbon without any post-production machining, shaping or finishing. Only the excess resin is sanded off. They do this by building up the rim bed and bead hook as a single piece, letting that section cure, then wrapping the lower section over it in the final mold. This lets them use the same rim bed section for both the Ksyrium and Cosmic Pro Carbon SL wheels. To form the bead hook, they use a soft plastic mold inside it during the heat molding process, then it’s simply pulled out. The thicker part of the hook (A) is a cord of wound carbon about a pencil lead’s thickness. The other thick section between the upper and lower bodies (B) is a slightly thicker cord. These allow the carbon to be built up to the necessary thicknesses quickly and easily, without requiring a ton of overwrap.

The result is an inner rim bed meets all ISO and ETRTO safety standards right out of the mold and is perfectly smooth. The inside of the rim is formed by using an ultra-thin bladder, which is inflated during the molding process to push the fibers against the metal molds from the inside out. This compacts the fibers and squeezes out excess resin. Mavic started using bladder molding for the Ksyrium Pro Carbon SL tubular launched last summer. Other models still wrap the carbon around a foam core, but one of Mavic’s carbon engineers told us as the rims get wider, the bladder becomes a lighter weight option. And it is light, barely registering in my hand when I held one…which is good because it’s left behind inside the rim as part of the molding process.

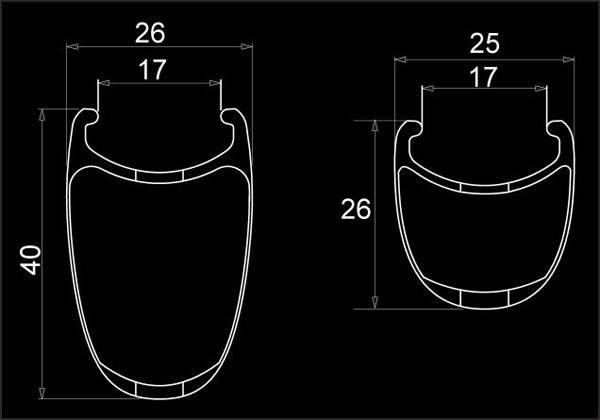

The inside width is 17mm for both the Cosmic (26mm external, 40mm deep) and Ksyrium (25mm external, 26mm deep). For comparison, the CC40 had a 13mm internal width, and the Ksyrium was already 17mm internal, but only 22mm external. Before you think “oh, but 17mm is so narrow, Mavic just doesn’t get it”, we let them explain:

First, there are few real standards when it comes to road wheel’s bead hook shape, tire and rim interface sizing, etc. (and even fewer if any for road tubeless, but that’s whole ‘nother story). Mavic’s brand goal is to be an “unbeatable combination of performance and reliability”. That last bit is why they are deliberate with new product development instead of pushing ahead with ultra wide rims and road tubeless offerings. They could do it, but they’re not confident it’s the right solution (which can be read as a hint that they’re working on their own solutions, just at a pace that doesn’t necessarily suit the rest of us). So, these are not tubeless ready.

So, the 17mm internal width is what they need to get the right tire shape to optimize ride quality, handling and rolling resistance. The wider 25mm (Ksyrium) and 26mm (Cosmic) external widths then optimize aerodynamics around that tire size, too. It’s also about safety:

A 25mm tire is the smallest you can use, and it’s the size the rim was designed for, but technically you could safely run up to a 50mm tire. So, running a 28 or 30 is no problem. They do not recommend using a tire narrower than 25mm because if a 23mm tire or smaller is on there and suddenly loses air pressure, it runs the risk of coming off the rim. So kids, bigger tires are better here, m’kay? Fortunately, the 25mm has quickly become all but standard in the pro peloton, and extremely popular among cyclists everywhere.

The extra width comes at no weight penalty, either. The rims are light, coming in at just 400g for the 26mm deep Ksyrium, and 450g for the 40mm Cosmic. Mavic’s wheel product manager says weight savings over the early prototypes with the alloy internal rim bed is only about 5g, because anything they removed in alloy was replaced in carbon.

Regarding aerodynamics, the rim shapes uses the now common rounded aerodynamic profile that’s slightly wider just below the brake track, and these numbers are with a 25mm tire. The drag chart above shows the new Cosmic Pro Carbon SL against it’s predecessor and several competing rims of similar depths. Only one averaged slightly lower drag, but all are close. To be honest, in this day and age, most aero wheels are so close to each other in average drag performance that what you’re looking for is something without drastic swings in drag as the yaw angle changes. A flatter line means a more stable wheel in gusts. The short of it is this: Mavic’s new wheels are aero and, in that regard, perform on par with the competition.

So, if it’s not aerodynamics that sets them apart, what does? Well, there’s the safety aspects of a stronger, one-piece molded rim. And there’s the braking performance, which is nothing short of remarkable.

Mavic developed a proprietary resin mix and curing process to withstand temps up to 200ºC, which they say is at the extreme end of what might be seen in real world conditions. The brake track consistency is also checked, and their molding process produces nearly zero surface variations. That means no grabby spots. Then they use a laser machining treatment on the braking surface to remove the outer resin coating and expose the fibers. This gives it enhanced friction in both wet and dry conditions, particularly when used with their own special blend of SwissStop yellow pads.

They tested with the SwissStop Black Prince pads, too, and performance was slightly better, but those pads were too aggressive for their rims. The laser machining leaves the fibers exposed, and they found the Black Prince pads were causing a little too much wear for their liking. So, it’s a custom yellow pad formulation for production.

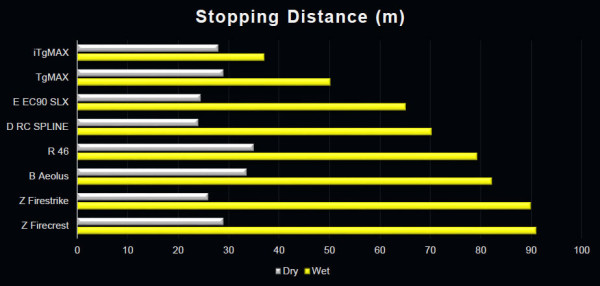

Mavic tested competing carbon clinchers’ braking performance in both dry and wet conditions, using the stock pads that are provided with each brand’s wheels. In dry conditions, each performed within a ~5m range. It’s the wet weather testing that showed massive differences, and if these hold up in real world riding, Mavic may have just solved the achilles’ heel of carbon rim braking, providing a more consistent, predictable stop regardless of weather.

Once it was proven in the lab, real world testing is done by riding down the Mont Ventoux and dragging the brakes continuously down the middle section of the mountain, which gives them a 10km run averaging about 10º decline. Heat buildup was measured using heat sensitive decals placed inside the rim bed.

We didn’t get a chance to test them in the rain, but I can say that their dry braking performance is astoundingly good. Whatever hype Mavic dishes out in this regard, the wheels live up to it.

The other part of improved braking performance is heat management, which we’ve already covered and is handled by their new iTgMax resin (i = integral, as in full carbon).

Or, you could just go with disc brakes.

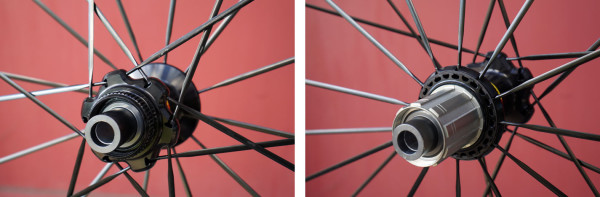

Both will be available with the Center Lock hubs, which also have the new “star ratchet” style toothed rings of the new Instant Drive 360 hubs.

The only difference in the disc brake rims is that they don’t receive the laser machining process, and the decals run right up to the edge.

Other hub details include:

- Same hubs that were introduced last summer on their All Road and tubular versions of the Ksyrium Carbon SL and Cosmic Carbon SL Tubulars.

- 40 teeth for a quick 9º engagement, which is a big improvement over the 17º two-pawl system it replaced.

- 12/15/QR front convertible

- 142×12/QR rear convertible

- All parts included, and switching them is a tool free affair. They’ll have a converter kit for 12×135, too. They’ll fit in the Specialized SCS system, too, if you replace the SCS derailleur hanger with the standard version available through Specialized.

COSMIC PRO CARBON SL CLINCHER

The Cosmic is Mavic’s mid-depth “fast and light” wheelset. Retail pricing is:

- Cosmic Pro Carbon SL C Disc (€2,090 / $2,399.90 / £1,550)

- Cosmic Pro Carbon SL C (€1,990 / $2,199.90 / £1,450)

The Cosmic gets 18 stainless steel spokes in the front, 24 in the rear. Those spokes have a new elliptical shape that improves aerodynamics, letting it ride just as fast as most 50mm deep wheels but at a lighter weight. They spent a lot of time testing and developing them, then they had to work closely with their supplier to get the manufacturing process right.

The complete wheelset weighs in at just 1,450g, and it comes with 700×25 Yksion Pro tires (front and rear specific) that weigh in at a claimed 210g apiece. Wheels come with custom yellow SwissStop carbon brake pads, skewers, bearing adjustment tool and rim tape. Disc brake wheels also include axle end caps for QR and thru axles.

KSYRIUM PRO CARBON SL CLINCHER

The Ksyrium is their shallower “endurance” line that’s intended to be the lightest offering. The wheels ship with the same goodies as the Ksyriums and retail for:

- Ksyrium Pro Carbon SL C Disc (€1,990 / $2,199.90 / £1,450)

- Ksyrium Pro Carbon SL C (€1,990 / $2,199.90 / £1,450)

The Ksyrium spokes are their flat alloy spokes, which are still using a NACA aero shape and are a little bit lighter weight. Wheelset weight is claimed at just 1,390g, something I appreciated on the thousands of feet of climbing we did during the launch in Nice, France.

The hubs are available with Shimano/SRAM, Campagnolo and SRAM XD-R freehub bodies. (Note: XD-R is simply a 1.7mm wider version of the XD Driver Body for mountain bikes, with the extra width to match up with current 11-speed road freehubs so it’ll fit inside bike frames correctly. Yes, we’re thinking that it opens up room for a 12th cog, too…)

For now, they don’t have 650B or Lefty versions to fit the Cannondale Slate. They’re not saying never, but it’s not on the immediate road map.

Stay tuned for first ride impressions, coming soon.

NEW DEMO & SERVICE PROGRAMS

They’re launching a free worldwide “Riding is Believing” test program through dealers, and you’ll be able to find a participating dealer and reserve a pair online at Mavic.com. The dealer will prep the wheels for you to pick up, and then you both have the opportunity to send feedback to Mavic. Starts April 15 in France and UK, then the rest of the world May 1. At launch, they’re looking to have up to 1,500 dealers on board with the Cosmic Carbon SL, then expand reach and models shortly thereafter.

Mavic Care Plus is the new extended warranty program that replaces their old plan at the end of August. MCP adds a year at no charge, extending the original warranty to three years. Plus, their carbon wheels are now included in the crash replacement program that lets you nab a replacement set for 40% off MSRP if they’re damaged outside of normal warranty issues. Lastly, warrantied wheels will now be able to be dropped off and replacements picked up where ever you want – your home, office or favorite Mavic dealer – in countries where Mavic is sold directly.