Introduced in Spring 2015, Venn Composites’ filament-wound carbon rim construction brought about an entirely new way to make rims. One that could be lighter without giving up strength or stiffness, all with a process that allows for perfect 100% repeatability and consistency from rim to rim. It’s also completely automated, which cuts down on manufacturing costs, and those savings are passed on to you and me.

The rim design uses a wide, NACA-like profile designed to improve aerodynamics on the relatively shallow 35mm depth. They’re tubeless ready and come in disc- or rim brake specific versions. We’ve been riding a set of the disc brake ones for about a year as part of our Project Road Bike, here’s how it’s going…

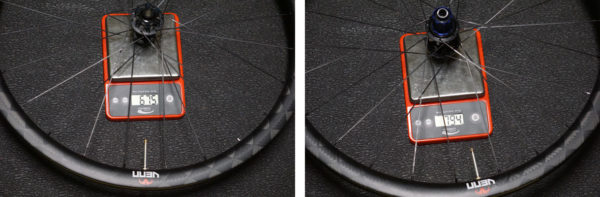

The complete wheelset uses Venn hubs laced 24/24 with bladed spokes and comes at 675g (front, 15mm thru axle) and 794g (rear, QR). The hubs are convertible to work with any modern axle type and fit 6-bolt brake rotors. Total wheelset weight = 1,471g.

I paired them with Hutchinson Fusion 3 RoadTubeless 700×23 and 700×25 tires. I’ve found to be very consistent in setup and performance, making them a good test partner.

I had one each of the 23mm and 25mm wide tires on hand, so I put the 25 on the front (left) and the 23 on the rear (right). Venn recommends a 23mm tire to optimize aerodynamics, which leaves a lot more of the rim’s upper edge exposed to the wind. They don’t provide charts and graphs and test results, but there’s plenty of research out there that suggests small lips can reduce turbulence, so maybe. Interestingly, I did notice that steering seemed just a tad more susceptible to crosswind gusts than some other, deeper aero wheels I’ve tested. So, A) it could be that a 23mm would have mitigated this, or B) the focus of these rims was on filament winding technology and not specifically on aerodynamics.

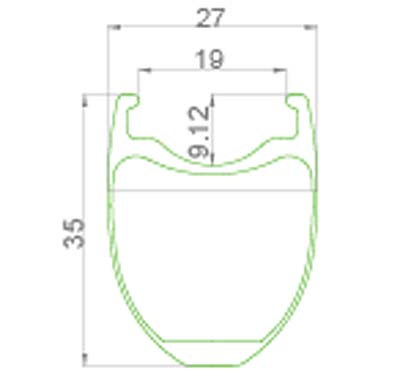

Measurements come in at 27mm at the widest, about 24.8mm at the top of the rim, and 19mm internal. That’s fairly wide for a 23mm tire recommendation, but good if you wanted to use these as an XC rim, which they say is perfectly safe. It also means they’re good for cyclocross.

UPDATE: These test wheels were first generation and used a rounded, U-shaped rim bed with no seat for the tire to “pop” into and secure its bead. But, the current generation of rim has a revised shape with proper tire shelfs to help hold the bead in place once inflated. While I can’t attest to its effectiveness, it’s a step in the right direction to improve the tubeless readiness of these otherwise fine wheels. Here’s what the current rim profile looks like, followed by my original comments about the test set of wheels I rode:

(ORIGINAL: …good for cyclocross…except (in my opinion) for one thing: There’s no tire bead channel to “lock” the tire into place as it’s inflated. With most tubeless ready rims, there’s some manner of flat or even channeled bead seat that the tire audibly pops into. This helps hold the tire in place should you lose air pressure…or just run really low pressures, as you might for cyclocross or mountain biking. Without this, the tire beads slide back down to the center of the rim’s U-shaped bed as they lose air. That shape makes for easy tire installation, but I’m a little worried what might happen should you experience a blowout. Thus far, I’ve had no problems while riding, though.)

The hubs are non-branded but worked fine. They rolled smooth and have had zero issues during testing.

Overall, the Venn REV 35 TCD wheels have been solid performers that introduce an exciting new rim construction technology to the market. And that is their strong suit. Aerodynamics are average compared to more sophisticated shapes, and tubeless readiness is questionable. But they’re light, and they’re stiff, and from a fabrication and durability standpoint, they’ve excelled. That, and they look bad ass:

The rims were laterally stiff throughout testing – slaloming, wiggling, hard cornering, fast sweepers, etc. They also rode well. These were mounted to the Culprit RoaDi, an alloy frame, with Culprit’s massively stiff stem connecting it to the bars. Even with these potentially firm sections between the wheels and my hands and arse, the ride never felt harsh.

The other claimed benefit to filament wound construction? Cost reduction. And that comes through in a retail price of just $938 for this wheelset. So, if you’re not sold on tubeless yet and don’t need the most aero wheelset, you can get a lightweight and otherwise exceptional set of full carbon rims laced up and ready to ride for under a grand.

This review wraps up our Project Road Bike build. While Culprit is transitioning out of the frame business to focus on components, they have limited inventory left. Check out Part One for details on the frame and cockpit, and Part Two for our review of Campagnolo Chorus EPS.