Born out of the boutique bike building experience of western Australia’s Flying Machine, a new custom carbon fiber frame upstart is taking hold down under. The new Perth-based Plane Frameworks is making a move to leverage their time spent tailor-making complete bikes into producing their own made-to-measure carbon fiber frames from the ground up in-house. They aren’t just replicating some other carbon frame building style either, they’ve developed an innovative new process to build fully custom geometry, one at a time with true one piece monocoque construction…

Flying Machine had started out pretty much outsourcing everything more than 8 years ago, but as time went by they started bring more assembly and finishing in-house and back to Perth. Every year that made more and more sense as they were incorporating more customization into the complete bikes they sold, so doing as much locally as possible just made more strategic sense.

Now the creation of Plane Frameworks takes it the next step further, custom fabricating the carbon frames to order in their own shop. The goal of the company is to set themselves apart internationally with an innovative new method of constructing the bikes that they have developed to let them build full custom geometry in a truly monocoque frame.

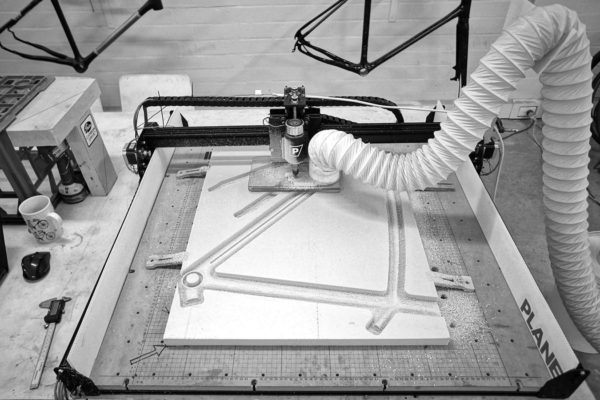

The secret of their customization seems to be in employing a one-time-use positive polystyrene mold, to create a fully made-to-measure frame in a single piece. While previously building monocoque frames has required very costly negative molds that made it often times prohibitively expensive for some companies to even offer a wide range of stock sizes, Plane’s machined EPS mold means every frame can get the benefits of being built as one piece, with the added benefit of a rider-specific layup.

One the mold is wrapped, Plane combines vacuum and external pressure to compress the resin soaked carbon as it sets, before popping the frame into an autoclave to cure it. When the frame is completed, that EPS stays inside where it doesn’t have much impact on weight but actually provides the added benefit of helping to damp vibrations.

You can go straight to Plane’s design and production studio to start the custom frame process, or go through a partner shop in a network they are just starting to establish. Plane will also work with professional bike fitters around the globe get you on a bike custom sized and tuned for your style of riding. For now Plane Frameworks have just two bikes on offer – the Road and the Gravel.

Road

The Road is actually more of an all-road bike and is intended to fit anything up to a 32mm tire. The details are of course fully custom, so while Plane can build a fairly typical road double setup for mechanical or electronic drivetrains, 1x, single speed, even belt-drive configurations are also possible.

What you will see is that they like to use modern 12mm thru-axles, 1x setups, modular dropouts, flat mount disc brakes, and integrated seat masts

Gravel

The Gravel adds in even more clearance to get farther off of smooth roads. Again fully customizable for geometry and drivetrain configuration, this one will clear up to a 45mm tire and gets paired with a similarly wide fork.

And being custom extends to the finish as well. Plane does their own painting in-house, so they’ll paint your frameset in any color you can imagine. Either a solid color with masked out logos to reveal the carbon below, or the opposite with a raw carbon look and any color logos. Pricing is set at $4500AUD (~$3350/3200€) for either bike, including the custom geo frame, standard custom color paint, and a color matched fork.

The new brand and its bikes have really just come on-line, and the company is seeking investors as it ramps up for a bigger production and a full-scale global launch. Until then, maybe you can be the first kid on the block pedaling a Plane.