We had the chance to join Shimano and their development team last week in Calpe on the Valencian coast in Spain for what had promised to be some warm winter miles test riding the new Dura-Ace Di2 groupset. In the end the weather dictated a different story. Unseasonably cold temperatures and a week of heavy rains made for conditions that did more to test the waterproofness of the new Di2. Then when rain turned to snow up the climbs away from the coast, it also meant a perfect playground to see how the first-ever Dura-Ace branded disc brakes would deal with bringing us back to a stop.

Luckily I came to Spain from Central Europe where we’ve had weeks on end of sub-freezing weather, so I pulled on the waterproof shorts, warmers, and gloves and got down to riding the new gear. Looking closely at the tech updates and refined details that make up the new group, Dura-Ace Di2 delivered the shifting that has become a benchmark with improved braking, more consistent ergonomics, and some interesting Synchro shift options…

We’ve covered the tech of the new Dura-Ace group in detail in a few different iterations since its debut this past summer, so I’ll try to separate that which stands out after actually spending time riding the new Di2 groupset here. You can find the tech from the entire R9100 series group here at its introduction, pricing details on the individual components here, a look at the new tubular, tubeless & clincher Dura-Ace wheel offerings here, and then the actual weights of the new Di2 components on our scales here.

That said, the reason we continue covering the new R9100 series Dura-Ace groupset in so much detail is that with the addition of options for rim brakes, disc brakes, mechanical shifting & Di2 electronic shifting there really are four distinct Dura-Ace groups available for 2017. And while it may seem like there is a lot of overlap (ie. cranksets, chain, cassettes, and even lever ergonomics), each variation seems like it might cater to a different element within the premium road market. Out of the four, I’ve now spent time riding R9100, R9150 & R9170 and I get the sense that I would personally spec them on three completely different types of bikes, and have an idea that the forth would suit an even different style of riding.

For these riding impression, I’m going to stick to new Di2, with the R9170 Di2 shift/hydraulic disc brake group the focus. As premium disc brake road bikes have started to catch up with their rim brake counterparts in pretty much every aspect, it is hard to argue with the improved braking of hydraulic discs.

Di2 Rear Derailleur

The core of the new Di2 groups R9150 & R9170 are the new electronic derailleurs. They borrow a lot of their shaping and layout from years of Shimano mountain derailleurs and the reasoning that made sense off-road makes equal sense now on the road. Two key technologies you see are a Direct Mount hanger option and an out-of-the-way Shadow profile.

Additionally, the slightly longer cage design adds compatibility with Dura-Ace’s new 11-30 cassette. This was apparently a direct response to pro riders and mechanics who weren’t happy to have to switch to mid-cage Ultegra derailleurs to get the wider 11-32 gearing they wanted for some of the recent races that started to include incredibly steep stretches of road. The 11-30 gearing was deemed to be sufficient with compact chainrings, and let the R9100 Dura-Ace stick with a single short cage length.

Shimano reiterated something we see quite often these days, that with the close spacing of modern 11 (&12) speed cassettes out of alignment derailleur hangers are the number one cause of poor shifting. Especially since Di2 derailleurs are both so string and precise, they need something stable to bolt onto. Shimano has decided to move to direct mount derailleurs going forward, and says they’ve been working with bike makers to start producing road bikes with direct mount hangers. No official word yet on which brands will take up direct mount hangers, but we’ve been told to expect it from at least a couple big brands within the next year.

That is additionally helpful with the move to thru-axles and short chainstays, as it moves the derailleur body’s first pivot a bit further back on the bike allowing more room to more easily and quickly drop the wheel out for fast wheel changes. Besides speed it also make the derailleur less likely to be bent in a wheel change.

Of course the much lower profile MTB-inherited Shadow layout also goes a long way to keeping that expensive derailleur out of harm’s way. Looking at the bike from behind, it is easy to see that the body of the derailleur now barely sticks out beyond the end of the axle, no matter what gear you are in. That makes the derailleur less likely to get torn off in a major pile-up in the peloton, but also reduces the impact to the derailleur and hanger in the most common crash where the rider just washes out in a turn.

A side benefit is that the new Di2 R9150 rear derailleur looks substantially less bulky visually with its servo motor tucked inside, more attached to the back of the parallelogram than the previous 9070 rear derailleur. That makes the group look more consistent from mechanical to electronic versions.

Di2 Front Derailleur

The new R9150 Di2 front derailleur gets a pretty good overhaul as well. It also incorporates a slightly less bulky looking servo motor, mostly as a result of reducing the large shiny silver body from the 9070 version. With the growth of wide tires on the road and short chainstays, Shimano has made an effort to improve clearance between the front derailleur and tire. That is most obvious on the big redesign of the new mechanical front derailleur, but this Di2 one gets trimmed as well.

At the same time the new R9100 crankset has increased its chainring spacing and refined its tooth shaping to make it work better with short chainstays, so the R9150 front derailleur gets updated accordingly. That is especially important as Shimano redesigned the new Dura-Ace front derailleurs so that they will work perfectly with either standard 130mm road spacing or the effective 135mm spacing (actual axle spacing of 142mm) that has become the norm with the addition of thru-axles and disc brakes. Shimano now says that you can get perfect shifting when using either standard width rear ends, down to short 410mm chainstays.

Besides slimming down and updating the spacing on the new Di2 front derailleur, it also gets updated wire management. It is a rather small item, but on a system that was already seen to offer the most precise shifting on the market, the small refinements are what make the case for the upgrade to R9150.

Again with tighter clearances between rear tire and front derailleur, the 9070 derailleur left cable routing up to the mechanic. As we have seen most recently in our Pro Bike features at the TDU, top mechanics have gotten good at cleanly routing the wires, but the new plastic guide that clips onto the end of the front derailleur wire and holds it in place promises lower profile routing without any guess work.

Disc Brakes

With the proper addition of hydraulic disc brakes to Dura-Ace the big concern was fitting everything inside the small lever bodies we’ve become accustomed to with mechanical Di2. While the non-series RS685/785 and RS505 hydraulic levers are much wider and more bulky than anything branded as Dura-Ace, Shimano promised with the R9100 series to deliver the same feel across all groups so that the pros could seamlessly jump from one bike to the next with the same feel.

To be honest I was personally a bit skeptical, but with the three 9100 levers I have ridden so far, they each feel the same to my hands. I broke out the calipers to measure each one to back up the feeling, and sure enough they are each the same width on the hoods (measured as 29mm wide just behind the brake lever pivot.) Back where the lever body transitions to the bar the disc brake bodies are slightly larger (42.5mm vs 41mm) where Shimano says they needed a bit more space to get the hydraulic lines into the body. After having spent a good bit of time riding the RS785 levers, the new R9170 levers just seem much smaller in the hand.

What hasn’t gotten much notice is that the new Di2 buttons offer improved tactile feedback of the click to shift. This has specifically been an issue for me (first world problem alert: regularly riding several different brand groupsets on the road and cross), where I didn’t always feel like I was getting positive feedback at the levers with each shift, especially when wearing cold weather gloves. Well, riding the new Di2 (in both rim & disc brake variants) in the foul weather resulted in cold, wet, and sometimes stiff fingers even in cold weather gloves, and I’m happy to say the shift action of the buttons seemed more tactile. It is still pushing a button vs. clicking a shift lever, but the feel is certainly improved.

Of course strong, reliable, and predictable stopping is the key to the addition of disc brakes in Dura-Ace’s new R9170 group. I’m a strong supporter of disc brakes on the road. I ride too often in nasty conditions to ever want to own a rim brake road bike again. But while I’ve ridden any number of road disc setups, this new Dura-Ace group is certainly the most refined and unified group I’ve pedaled and stopped.

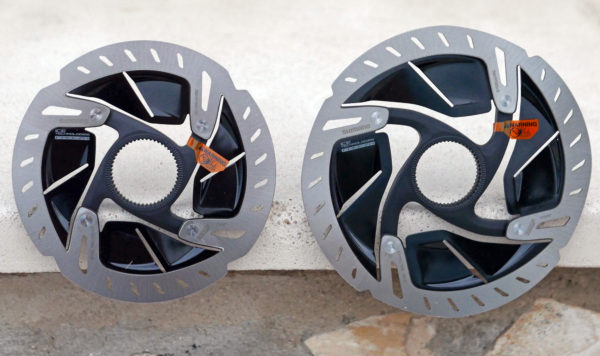

It really is hard to beat Shimano’s IceTech and Freeza rotor technology. On the road I have yet to try any combination that matches the balanced performance of initial bite, predictable modulation, and overall power. The new Dura-Ace RT900 rotors – available only in centerlock and either 140mm or 160mm diameters – seem to offer all the performance I have come to appreciate from their XTR RT99 predecessor, and even claim improved heat management performance.

We’ve seen computer renderings of another Dura-Ace rotor design with the same product numbers that does not use a separate alloy spider like these (or the XTR rotors) and promising improved heat dissipation, but this is the only design we’ve seen in the real world. Curiously, with aerodynamics being a key driver in current road bike design, Shimano tells us that they didn’t specifically test or measure the drag effects of this more closed rotor vs. the more open previous IceTech or Freeza designs. Instead the rotor fins were designed in order to optimize cooling.

One issue to not forget when adding an integrated hydraulic disc brake solution to your road bike is that setup is certainly more complicated. While installing and bleeding most mountain bike disc brake setups has become more simple and straight forward over time, the new Dura-Ace is not there yet. With complicated internal hose routing, even inside of some handlebars, dialing in your disc brake road setup can be a challenge. And with the constrains of fitting the master cylinder into that small hood, Shimano didn’t manage to position the bleed ports on both lever and brake body where they are easily accessed.

Bleeding the brakes isn’t something you are going to be doing often, but when it is required, it will be important that you or your friendly neighborhood mechanic follows Shimano’s instructions closely so you get it right the first time.

All in all the combination of Shimano hydraulic disc braking and Di2 shifting was pretty much everything we had hoped for, especially when riding in rain and snow right around freezing temperatures. Braking was perfectly consistent and powerful from my first pull of the lever, and shifts popped off as quickly as I tapped the shift buttons.

The only ergonomic thing that didn’t entirely please me with the R9170 levers was the limited reach adjustment of the brake levers. With the Di2 setup placing one shift button behind the other (both behind the brake lever blade), there isn’t a lot of extra room for your fingers behind the levers. If you are like me and ride on the hoods with one finger on the brake lever and the remaining three wrapped around the bar behind the lever, you might also pinch your fingers between the lever and bar when braking heavily (especially with gloves on). The levers do offer reach adjust, but mine were set in the long (all the way out) position, and since there isn’t a real way to adjust pad contact position like on the mountain bike, it took me a couple of rides to get used to where best to position my hands for optimal braking.

Synchro Shift

Now with the core details of the Di2 group out-of-the-way there are a few other tricks up its sleeve worth looking at, some of which we’ll get into even more detail another time. The first is the new A-Junction box which now can be mounted inside of your bar end, so you get rid of having it hung by a rubber band under your stem. Functionality carries over, but it also adds control of Synchro Shift.

Like we saw on the mountain bike Di2, Synchro shift has application on the road now as well (and can even be retrofitted to 9070 with a few small component upgrades). While off-road the goal is to drop the left shifter, on the road the point is to ease regular operation and to add full front & rear shift capability with two simple buttons in a aero position.

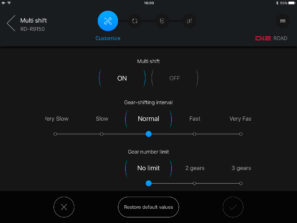

Synchro Shift has three modes in Dura-Ace: manual were you shift normally; Semi-Synchro where the rear derailleur moves one or two shifts to maintain smooth cadence with each front shift; or Full Synchro that lets you shift just the rear derailleur and controls the front automatically at preset shift points to maintain the best gear combinations (while also still letting you shift the front derailleur manually if you want).

To switch modes you need to double push the small stiff button on the bar end controller, which we found to be something you have to stop the bike to execute reliably. We spent time in each mode and probably still prefer full manual operation, but the Semi-Synchro is a nice feature and does a fine job of performing just like I already ride Di2, dumping a couple of rear shifts at the same time as shifting up front, although in theory the automatic control should be better at timing the paired shifts for the most reliable performance. Full Synchro we’ll reserve for the time trial bike, when it could be nice to have riding stretched out in an aero tuck.

App-based Customization

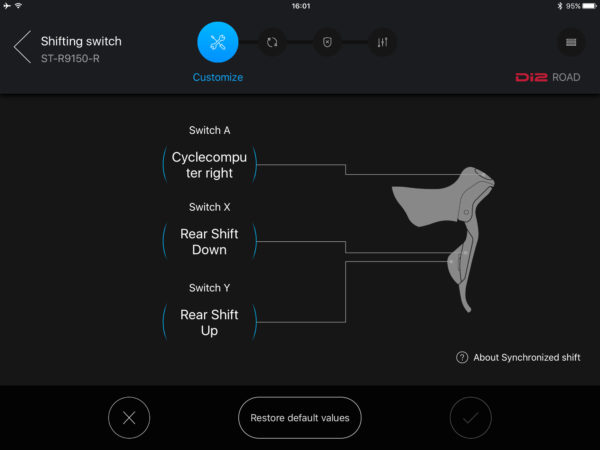

Key to the continued development of Di2 is customization. The newest version of the group is controlled by a suite of customization apps for mobile phones, tablets, and PCs that let you set how each button on the Di2 ecosystem reacts. We’ve seen the top buttons (above left) controlling everything from cyclocomputer screens to headlights, and even as additional shift buttons. There are a lot of options for flexibility, and Shimano continues to be willing to work with third parties to partially open up the group’s ANT Private communication protocol to allow more electronic integration going forward.

There is a lot to be said for app-based Di2 setup and customization. Whether you want to decide how many gears to drop with each front shift in Semi-Synchro, or how fast and how many gears to dump in Multi-Shift, the possibilities are there for you to play with, and find what suits each rider (or team) best. And after having to just plug my watch into my laptop to update its firmware, there is a lot to be said for being able to update your electronic drivetrain to the newest firmware (and possibly additional functionality) all from your Bluetooth paired mobile phone or tablet.

There really are lots of small refinements in the new R9100 series Dura-Ace Di2. There’s that new smaller Wireless Control unit that now fits inline in your E-tube wiring harness to give you the Bluetooth connectivity (and that can be installed inline anywhere in the system, especially helpful for internally routed setups). You can even wire in the external display that is a part of the mountain bike Di2 group if you want to see gearing info, but don’t want to just pair the groupset with a Garmin GPS. There is even a slightly updated remote shifter layout that includes zip tie channels so that it can also be securely mounted on bar tops outside on the bar tape.

Final Thoughts

We spent a few days riding the new R9150 & R9170 Di2 groups in the worst weather you could ever hope for on a road. bike. Through hours in freezing rain in groups exclusively on new Di2 (and even some flooded roads that were probably past the point of being reasonable) we never had an trouble with the electronics. And with many a rider finishing with less feeling in their finger tips than when we started, no one complained of mis-shifts or difficulty braking.

Like any new groupset the new Di2 takes a little getting used to. But coming off of the previous generation, it really was easy to hop right on the bikes and ride away. It does seem like with each new drivetrain iteration, their setup becomes a little more technical and even finicky. We spoke to Shimano’s designers and service course mechanics about the new group and both really stressed how important it is to follow the step-by-step instructions for setting these groups up. While in the past you could slap a new group on a bike and just tension four wires to pedal away, now there is a precise order of operations that if you jump over one step you might end up not getting the full braking power or instantaneous front shifting that are otherwise designed into the groupset.

Shimano is all about a total complete system as designed. Not many consumers are going to buy part of a Dura-Ace group, but after seeing a few pro teams piecemeal together 9000 and R9100 groups it is clear to see that the benefits of the new group are the top-level performance that comes from riding a complete group. The addition of brake and shift options though means that there really isn’t much of a need for compromise. Whether you want the fastest shifting Di2, lightest setup for road racing, or the improved braking and no reliance on batteries to shift, the new Dura-Ace has got you covered. I’m looking forward to spending more time on the new Dura-Ace disc brakes and maybe a bit more head-to-head between the mechanical and Di2 varieties.