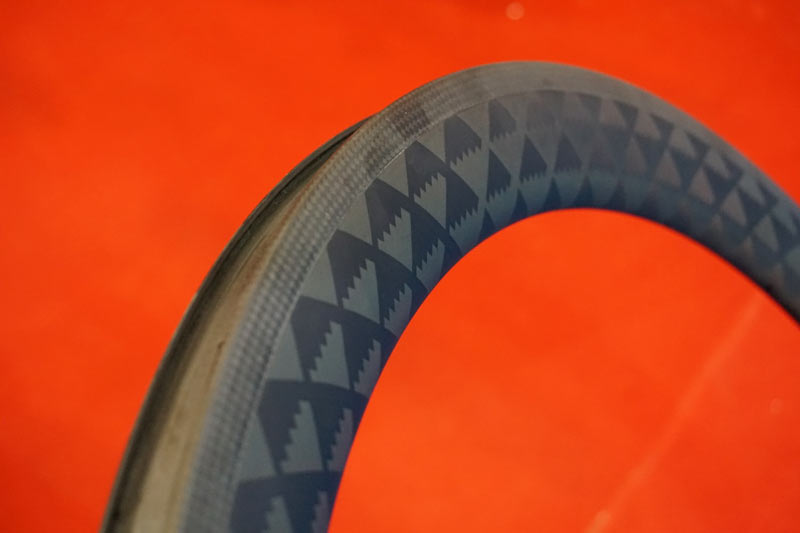

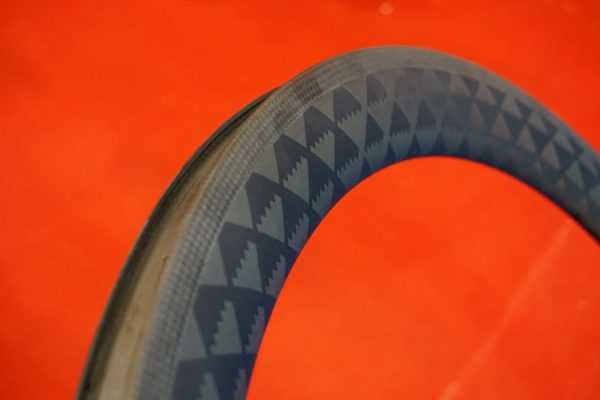

Venn Composites has found a way to make their filament wound carbon rims with a deeper profile, which founder Victor Major says is incredibly difficult to do and keep the fibers straight. Straight is the optimal orientation for maximizing the benefits and strength of carbon, but as the rounded aero profile gets deeper, the fibers naturally want to form a curve. Solving this problem, which he won’t say exactly how they’re doing it, has let them add a new option to the original 35mm version we reviewed…

They’ve brought the profile out to 50.7mm deep on this new Venn Rev 507 rim. That’s the deepest they’ve been able to pull off without getting into curvature issues…so far. The difference is that these are mechanically constructed using a true filament wound process, not laid up in panels and sections like a traditional carbon rim. Check that first link up above for the full story on filament winding versions laying up sheets.

Major says these prototypes are just under 500g, tubeless ready, but they’re thinking they can get it down to 440g for production. Expect them to be about $300 retail, measuring 21mm wide internally, with a shape aerodynamically optimized for a 25mm tire.

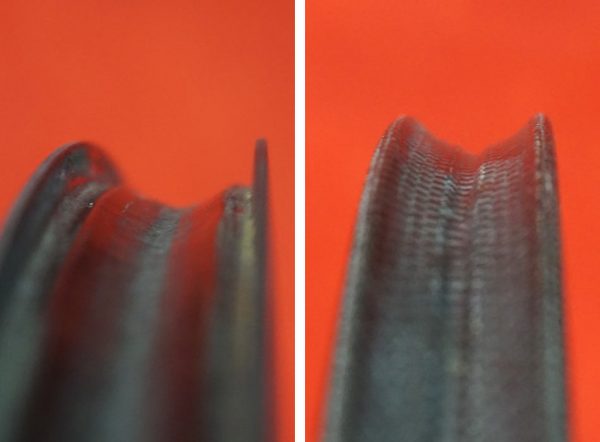

He also showed off a hookless bead prototype that stretches it out to 25mm inside. That puts it into the CX/gravel and 29er XC market because it’s too wide for normal road tires without completely messing up the tire’s mounted profile.

Venn will also have it as a tubular, designed specifically for 25mm tires to have perfect adhesion thanks to a 12.5° radius on the edges and a deeper seat. This gives it optimal tire placement and aerodynamics.