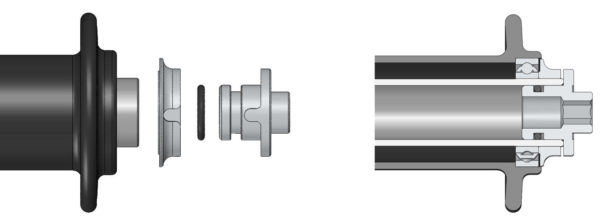

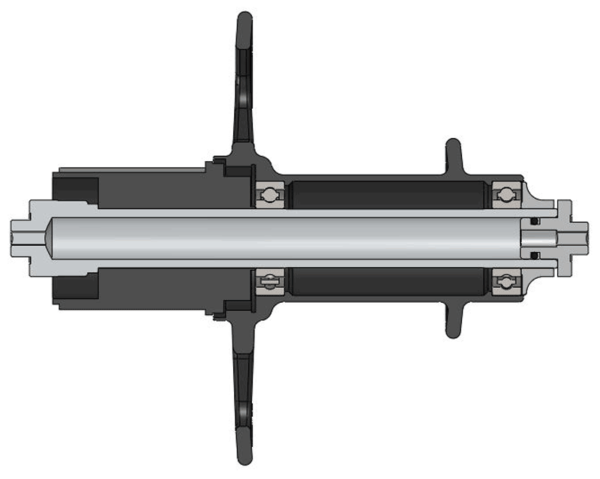

In January, Alto Cycling unveiled an all-new version of their very smooth road hubs, using a pinch/press fit to tighten things up without putting any pressure on the bearings. Ultra tight tolerances let them do that without having any play or wiggle between the hub and axle, and this video shows how they do it. Click past the break for a couple photos, and check this post for more details…