Few brands elicit as emotional a response as Specialized, and to walk around their offices, the passion is pervasive. And it’s easy to see why. Behind these doors are the usual assortment of cubicles and desks, but they’re tucked around huge open spaces, killer play areas, a massive R&D lab, and an entire room dedicated to nothing more than designer Robert Egger’s one-off custom creations. Curious to see how the Big Red S houses their employees?

Walk in the front door and their museum is directly to your right. It’s open to the public, so swing by anytime. We’ll come back around to it later in this post. Take a left and you roll up on the cafeteria…

…where they have Bagel & Donut Fridays. Free pastries, cold-brew coffee, kombucha, yogurt and other delicious snacks. We lucked out that we just happened to visit on Friday! The official reason for the weekly smorgasbord is to bring a couple hundred employees from all departments together to mingle. Another reason might be because they’re sort of in Silicon Valley (the outskirts, anyway) and fancy lunch programs as employee perks are common. Any other time of day, there’s a full cafe with fresh and hot lunches, smoothies, salad bar and more.

Directly across the hallway is their Body Geometry fit studio. They have multiple work stations so they can handle training classes, and they are testing new scanning equipment (more on that in a separate post). The Retül fit bike sits on the platform…Specialized bought that brand a few years back and offers several packages for sale to retailers and fitters, whether you’re a “S” dealer or not, but the software for matching you to a bike is specific to their bikes.

Around the corner are the locker rooms with more showers than I’ve ever seen at any headquarters. With so many employees (most, from the lunch time bustle) head out for mid-day rides, then grab lunch when they get back. Lockers, towel service and soap is all provided. Honestly, it’s pretty impressive. I didn’t grab a photo, but there’s also tons of indoor bike parking…

…and this giant workshop (on left). Employees get deals on bikes, and they get assembled here. And if memory serves, they have access to this enormous room full of tools and supplies to tinker with their own bikes. There’s also a rental program (free) so they can check out any of Specialized’s bikes to try out for a week. Then return it and try something else. Then something else. And so on.

The play area sits central inside the main building. To the right, through that opening, are offices. If we head down the path on the left and take a sharp left, we get to their Apparel Lab:

Inside here they can prototype and customize any piece of clothing. This is where their apparel gets designed and tested, and where sponsored pro athletes can get things tailored for them.

They even have rolls of technical fabrics and a custom sublimation printer and heat press to create one-off jerseys, shorts and other kit for top athletes or special events. On the table are some of the printed patterns for a pair of bib shorts, laying behind two custom tops they did recently.

Keep walking down that path and you come to a wide open area that’ll soon be converted to additional R&D space. Turn to your right and you’ll see the key-card accessed R&D lab of Specialized designer Robert Egger…inside which very few photos were allowed (despite our pleading). Here’s what we can show you:

They have their own paint booth for special editions. And, if you work there and will pay for the paint, they’ll create your dream paint job for nothing more than the cost of supplies.

If you know what you’re doing around an airbrush, they’ll even let you try painting it yourself.

Let their pros handle it and designs go from this…

…to this. This particular bike was nicknamed the Disney Cruise Ship thanks to its color selection and details, like deep sparkle paint.

Inside the walls was one of several small trailers they’ve built, shown here in extreme closeup because there was a bike in front of it that we weren’t supposed to photo. Inside is a desk, letting it serve as a private workspace when you need to focus. Most all of the offices are open floor plan, so finding one of these offers a little solitude.

Circle around and you’ll be skirting an oversized concept showroom bike shop, which was locked up with covered windows. Outside it was a (likely replica) VW bus that Sinyard sold to pay for his trip to Europe, which is where he happened upon the right contacts that led to importing parts…which is how Specialized started. Keep reading…

As if the coffee machines in the cafeteria weren’t enough, several office halls have their own coffee stations with pour-over equipment. Seriously.

A big part of their dealer training is SBCU, which has this workshop for technical lessons on things like BRAIN shocks and forks and other parts, plus a classroom outside with props…

…like this to help dealers spot the difference between real Specialized bikes and counterfeits.

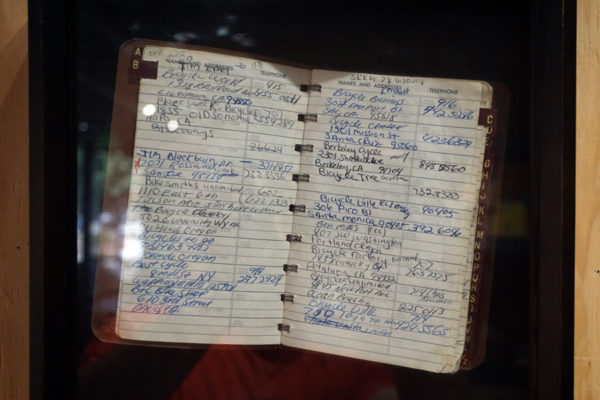

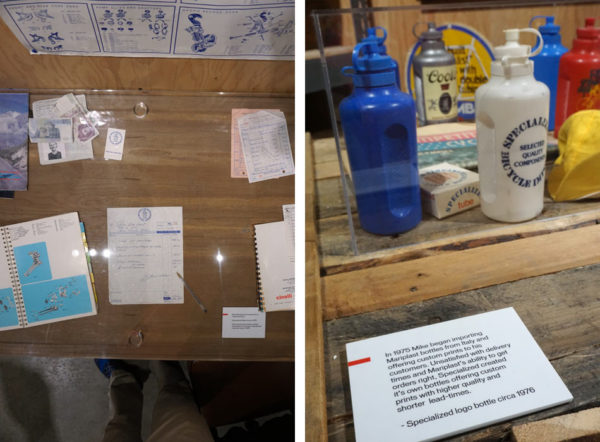

And now we’re back to the museum. Inside is a replica of Mike Sinyard’s first office, which (according to legend) wasn’t much more than a stock room with a desk.

Sinyard got his start importing high end parts from Europe that were hard or impossible to find in the states. The bike in the first museum photo was the 1971 Holdsworth bicycle and trailer (which was outfitted with tubulars) used to deliver Bay Area orders.

Sinyard, at the beginning.

After a few years of importing products and then making tires, Specialized started with bikes…like this 1981 Sequoia built by Yoshi Kono, the noted “San Rensho” Keirin frame builder in Japan.

This one’s a prototype Stumpjumper from 1983.

A 1987 Specialized Allez.

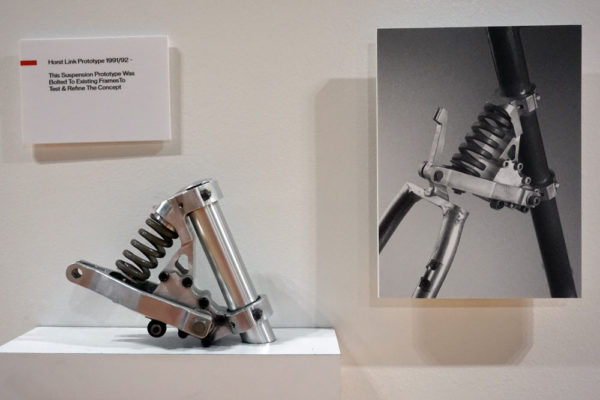

The original full suspension bikes started out as modified hardtails with this unit to test the Horst Link.

Which became bikes like this FSR downhill model for Shawn Palmer in 1996.

Looks about like today’s enduro bikes, no? No.

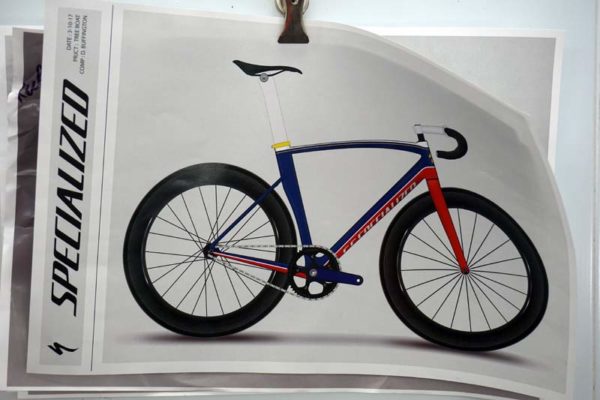

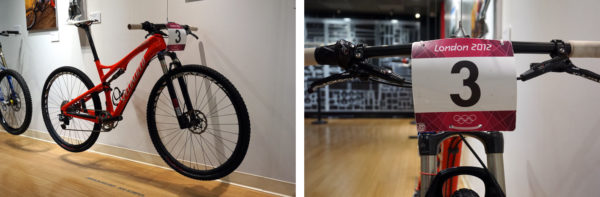

Things progress quickly, showcasing more modern machines like Jaroslav Kulhavy’s 2012 Olympic XC race bike…

And Olympic gold medalist Gwen Jorgensen’s 2016 Amira road bike with heat sensitive Torch paint.

Other memorabilia is scattered about, like this 1990 Specialized/Dupont tai-spoke aero wheel designed using a Cray Supercomputer. They say it’s so good, the design is still in use today.

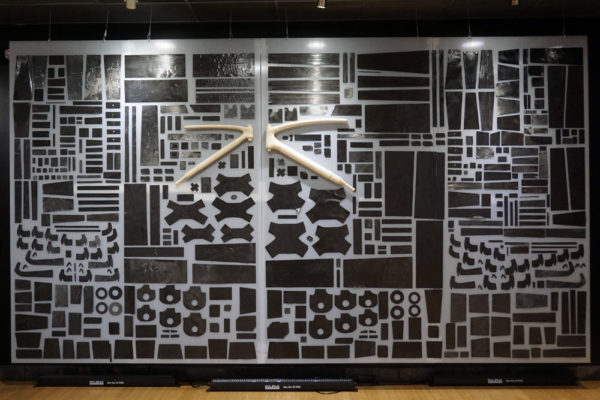

An entire wall shows off the different carbon pieces used to create different size frames. Size specific layups aren’t exclusive to Specialized, but it’s pretty cool to see it laid out life size.

Want more? Check out our tour of the Win Tunnel, and stay tuned for a gallery of prototypes and one-off concepts found on the second floor of the museum!