When Specialized set out to create their S-Works Carbon Power Cranks, they started with a lofty list of objectives. Topping the list was accuracy. Although they wanted their meter to be light, durable, reliable, and easy to use, accuracy in all conditions was the most important box they had to tick. To achieve that end, they had to call their scientific ace—Rodger Kram, Ph.D.

Kram has spent a lifetime studying physiology and the biomechanics of terrestrial locomotion. He’s the guy to call when you want to know the exact metabolic energy expenditure of an ant—or an elephant. Yes, he has already done the study. When the Olympic Committee wanted to know if sprinter Oscar Pristorius had an unfair advantage running with the aid of his lower-leg prosthetics, it was Kram who did the computations. If you have some time to kill, you can read Kram’s 200+ scientific studies listed just on Google alone. In order for Specialized to claim their meter was the most accurate in the world, they needed Kram to prove it.

Whereas most power meters are tested in labs using a basic lever and strain gauge, Kram knew he needed to create a more accurate, real-world testing platform. A longtime advocate of treadmills, Kram’s tests distill the variables to the basic metrics of time, mass, and length. Using his lab at the University of Colorado, Kram and his international tribe of fellow doctorates built a full-size treadmill capable of measuring the exact energy expenditure of a rider on a bike. Unlike other test scenarios whereby the rider is perched atop a bike fixed to a trainer, the treadmill provides the most realistic readings. The level of exertion could then be correlated to watts recorded at the crank.

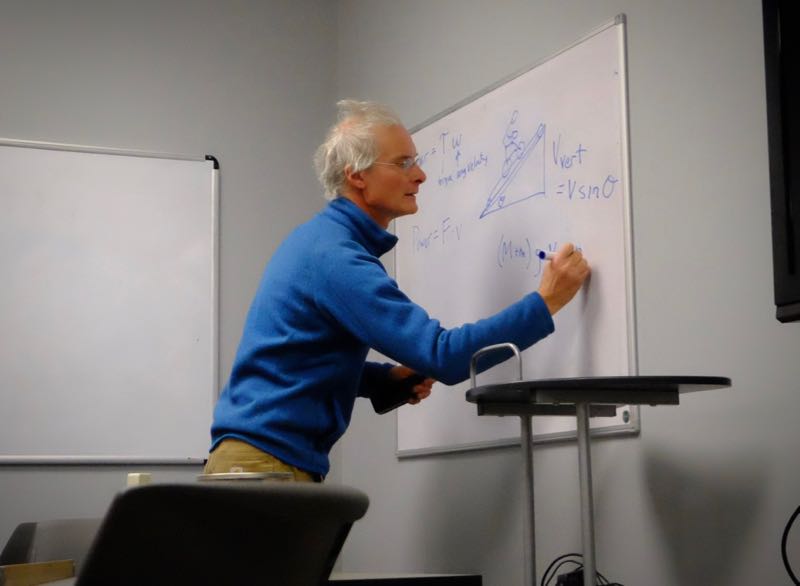

To attain the most accurate measurements, Kram and his team had to fold in a host of computations and controls. As Kram walked our team of journalists through the testing process you could smell the fug of frying brain synapses. It was a lot to pretend to understand.

In the most general overview, the treadmill tests were rather simple. A motor turned the treadmill at a consistent rate with a specific watt output. The treadmill was put on an incline to force the rider to pedal with enough force to stay in position on the belt. The rider’s output had to match the treadmill motor’s output. That’s the simpleton’s overview. But, nothing is that simple.

In order to calculate the wattage perfectly, several variables had to be addressed. The belt generates heat, and that heat had to be factored into the test. While there is no wind drag, there is spoke churn. That resistance had to be considered. The weight of the rider and the slope of the treadmill had to be in perfect balance. Every time the rider took a sip of water, it was included in the test calculations. If they sweated too much, that too had to be offset.

When asked if there were formulas used to negate drivetrain drag, Kram seemed a bit nonplussed. Drivetrain loss appears to be the Loch Ness Monster of locomotive testing. Although not perfectly quantified, multiple experts have estimated the mechanical drag of a bicycle’s drivetrain at around 2%. While they can’t isolate drivetrain drag and mechanically measure it, they can arrive at that number value by other means. So, 2% it is.

The most mind-bending calculation Kram and his team considered in their testing was the precise impact of the earth’s gravity as it pulled the rider down the slope of the treadmill. Gravity is not the same wherever you go. Ask Kram what the specific pull of gravity is for Boulder, Colorado and he’ll have the answer.

As the testing progressed, more criteria were introduced. The S-Works power cranks were tossed in a freezer then heated to such a high temperature they had to be handled with oven mitts. They were calibrated when hot, then tested cold. They even scrutinized the meter’s readings with the drivetrain heavily cross-chained. In that test, they found cross-chaining had minimal effect on crank-based meters but did impact spider-based units considerably.

After weeks of testing with the Specialized engineering team, their new cranks appeared to live up to their claims as the most accurate power meter on the market. They were ready for launch but needed real-world road testing.

They took the cranks outside — and they didn’t work.

When Scientists Become Detectives

While talking with Chris Yu of Specialized, he mentioned the accuracy setback that befuddled the engineering team and delayed the product launch. During the initial road tests, a couple of riders had reported random accuracy discrepancies from right to left crank. Because they’re incredibly smart, the Specialized team recreated the riding scenarios and made a critical observation. As riders pedaled north or south, east or west, the sun was imparting unexpected thermal imbalances from crank to crank. In short, the sun was warming one arm and not the other. Although it didn’t effect aluminum crankarms, it was something they had to address with carbon arms. Fortunately all it took was a simple tweak of the software and the fix was made. After more testing, the Specialized confirmed the accuracy of the meter at +/- 1.5%.

More than just a power meter tester

The more time we spent with Kram’s treadmill, the more we all began to see its possibilities. Just as Specialized uses their Win Tunnel to test aerodynamic drag, their treadmill (Specialized now has their own in Morgan Hill, CA…called the Win Mill) can be used to test just about anything not impacted by airspeed. They can test tire drag in real-world conditions with a minimum of variables. They can measure the drag of a straight-line sprinter and a rider with a wiggly front wheel. It’s possible to fold in additional tools like infrared cameras and Retul measurement systems to better evaluate locomotive efficiency.

Which means all of the development time, effort and resources that went into creating the new Power Cranks is just the beginning. And with Kram’s brain involved, the sky is the limit.