Mavic has combined two of their highest end features into one all-new wheelset that’s ready for pro-level racing. Which is one reason why they’re starting with a rim brake version of the Cosmic Ultimate UST, a full carbon wheel that’s tubeless ready and based on the UST design standard. While the pros might still be racing the grand tours on tubulars, they’re often training on regular tires. And more and more often, those are tubeless, which is proving to offer lower rolling resistance in test after test. All of which is to say that you, as a non-pro, can now get a wheelset and tire combo that’s arguably better than what the pros are racing on.

The new Cosmic Ultimate UST wheels introduce a couple of firsts for Mavic. They’re the first to get a full carbon rear hub shell and full length, rim-to-rim carbon spokes on both sides of the wheel. They’re also the first to get a new, heavily machined freehub body with lighter bearings. The result is a 1,310g full carbon wheelset that’s tubeless ready out of the box, no rim tape needed.

Creating a one-piece UST carbon wheel

The wheels use a Monobloc structure that’s light and stiff because everything is made into a single piece. There are no holes in the rim (other than for the valve stem), which makes it stiffer and stronger. The carbon clincher tech developed for their Cosmic Pro Carbon release in 2016 carries over here. That means the interior rim bed and bead hooks are fully molded, not machined, so fibers remain intact and run all the way around the top of the bead from side to side. This, too, improves strength, and gives the rim the ability to better combat tire pressures pushing outward as braking forces create heat. More on braking in a minute.

First, a little history to explain the rim’s design. The Cosmic Ultimate started using their hard foam internal in 2006 when they introduced the full carbon rim/spoke/hub design. That model used more of a “V” shape that let the spokes lay parallel with the rim wall. In 2015, they moved to a rounded profile for two reasons. First, because that’s the current best design in terms of overall aero performance. Second, because they wanted to reduce hard, sharp corners, which are not a great design for carbon fiber. Carbon likes smooth, round transitions, not sharp angles, so this created a stronger, better rim. The challenge then became running full carbon spokes straight into rounded rims.

To do this, they started notching the foam mold to make room for the spoke’s “head”, which is an over-wrapped piece of foam that slots into the notches. This wrapped section contains its own small piece of foam, which provides the structure and shape so that when it’s all heated in the mold and pressed together, it creates the desired rim profile and creates a one-piece rim/spoke combo.

Those wheels were only offered in tubulars, which are easier to mold. So the next challenge was to create not just a clincher, but a UST tubeless-ready clincher. Mavic says tubeless tires put more pressure on a rim, which actually impacts the spoke tension by compressing the rim radially. With a tubular, the pressure is self contained and has minimal impact on spoke tension. With a tube, that force is amplified because the tube is pressing against the rim bed. With tubeless, it’s even more. Enough that it requires 10% more spoke tension on their tubeless wheels to end up with the same overall tension with a tire installed and inflated. This keeps the wheels laterally stiff enough, but won’t impact rider comfort even if you have to put a tube in it.

Braking performance, spokes & tech specs

The rims measure 40mm deep, 26mm wide, and 19mm internal. They’re designed around a 25mm tire, and will come with the 700×25 Yksion Pro UST tires and Mavic’s own sealant (made for them by Joe’s No Flats). The spokes are 100% UD carbon fiber and weigh 35% less than comparable steel spokes, but have no elongation so create a laterally and torsionally stiffer wheel. But, like any spoke of any material, they can flex when de-tensioned (like when you hit a bump and compress the wheel slightly), so these won’t feel any more or less harsh than any other quality wheel. In fact, we had quite an interesting conversation with Mavic about spoke tension that we’ll turn into a full tech article soon.

The front rim is symmetrical, but the rear gets an asymmetric design to better balance spoke tension.

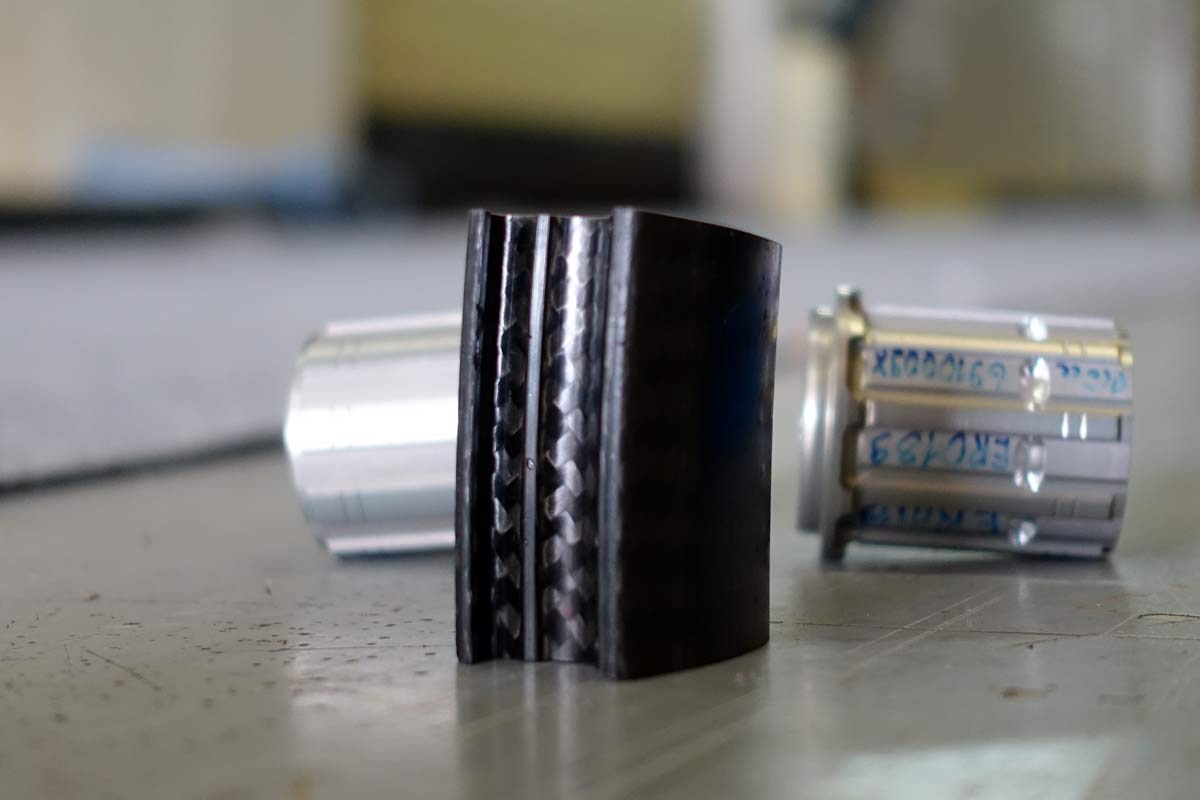

The rims use their laser etched braking surface for maximum friction. This was also introduced on the Cosmic Pro Carbon wheels, using a laser to remove the resin from the outer layer of carbon. The result is a rougher surface that creates more friction for better braking performance, wet or dry. That process hasn’t changed, but they did develop new, softer brake pads… and they’re not yellow!

We’re all for branding, but Mavic’s original yellow pads for their carbon rims created a LOT of yellow dust. Seriously, check out these photos from our test rides at that launch. They worked really well, but there was room for improvement beyond just aesthetics. The new compound is softer, so it grabs better and is less likely to damage the rim. Technically, you can still run the yellow pads on these, and they won’t actually damage the rim, but because the fibers are exposed and they will heat up, you might be able to see the woven pattern get a little misshapen over time. That’s normal, according to Mavic. But the new pads will do that less, and they’re replacing the yellow pads altogether. That said, they strongly recommend (and require it to maintain your warranty) you use their pads because harder pads (even the excellent SwissStop Black Prince) can damage the rims.

And you’ll want to keep that warranty valid because they offer a crash replacement program. They can even true them slightly on the off chance you manage to bend something that, technically, shouldn’t bend.

The pads are made for them by SwissStop, and Mavic says their dry weather performance is a little better than the yellow ones. But the wet weather performance is drastically improved. We tested that in person at the launch, stay tuned for first impressions in a separate story.

Aerodynamic performance

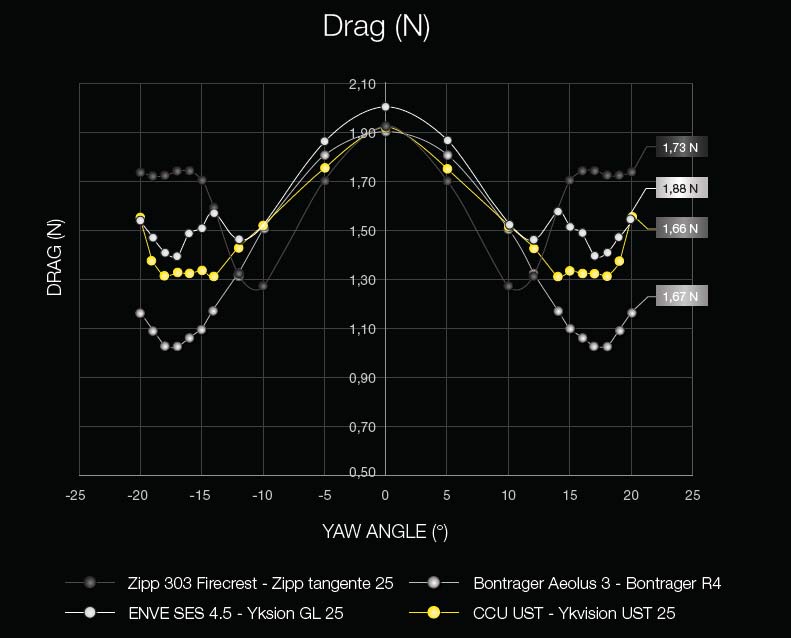

Mavic tested these wheels against other popular options with similar depths, using 25mm tires on all of them. The chart above shows the results, with a weighted average drag measurement on the left. By “weighted” they explained that each yaw value was weighted based on the amount of time you’re likely to spend riding in those crosswinds. So, the 20º crosswind drag figure has less impact on the average then 5º. Basically, they took a ton of real world riding data to determine what the most common wind conditions are and tried to come up with a number that made real world sense. Aerodynamics are on par with things like the Zipp 303, Aeolus 3, ENVE SES 4.5′ all measured with 25mm tires installed. Some had lower drags at different angles, but in the sweet spots, these compare very favorably. But, if they don’t have the best numbers overall, why share this data? Because these are lighter, have the benefit of UST standardization, and probably won’t come out of true.

It’s not all about the rim shape. The spokes have an elliptical shape for better aerodynamics, too. and the new hubs are smaller to be more aero.

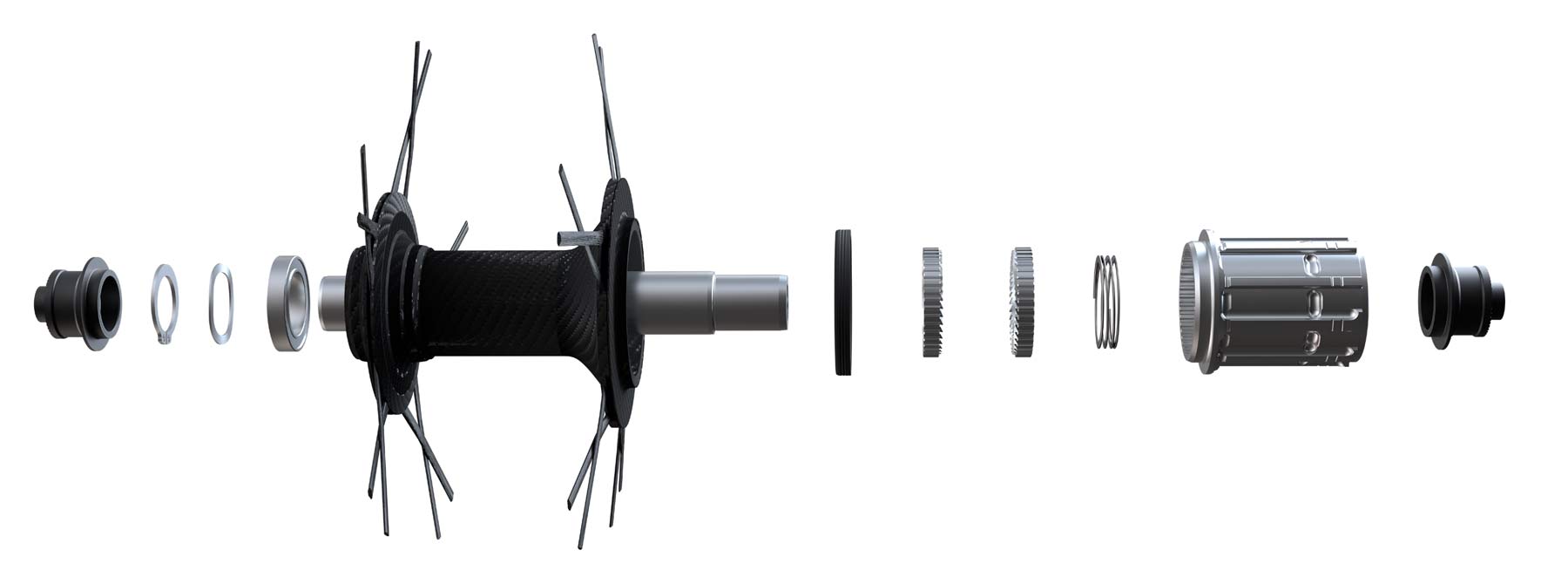

New full carbon hubs

The rear hub is now full carbon, their first update to the Cosmic Carbone Ultimate Tubular rear hub, which launched in 2006. That, along with the ability to run full length, full carbon spokes on both sides of the wheels, saves about 70g in that area. All in, the tubular comes in at 1,250g currently, but by the time they apply all this new design tech those should be around 1,180g (target weight).

The QRM Auto preload system uses a simple wave washer to automatically provide the right amount of preload on the bearings. For these wheels, it’s only on the rear, using their QRM+ manual adjustable preload on the front. Some of their other front wheels do use the new Auto system, though. Compared to a standard preload adjustment, this saves weight and has enough “spring” in it to take up any play that could develop in the bearings’ useable life.

There’s also a new freehub body that has additional machining inside and out, thinner splines and smaller, lighter bearings.

Internally, the ratchet-ring driven ID360 mechanism was introduced in 2015 with their All Road wheels and is now on most of their the carbon wheels and the Ksyrium Pro UST…and all of their disc brake wheels, including the entry level Aksium, because it’s thru-axle compatible.

During construction, the spokes are molded into the rims. Each spoke is pre-made and shaped, then molded into the rim during to create one piece. From there, the hub shells are inserted, the spokes are positioned over the flanges and glued into place.

Then, an outer flange cover is placed on it and they’re put back into a heated, pressurized mold to finish them. The end result ins a one-piece, full carbon wheel save for the bearings, axles and freehub system.

What about disc brakes?

The goal here was to provide the simplicity of tubeless on their absolute best technology. There is a plan for disc brake versions. And they admit that’s where everything is headed. Creating a rim brake version of this wheel was actually harder to make, but they wanted their pro racers to have it (and their racers wanted it). Since at this very highest end of their range, the volume is low, there was enough of a business case to move forward with what the racers wanted first. Fortunately for the rest of us, the hard work is done, and they’ll be ready with a disc version soon enough.

UST tires come with them

And this is actually a big part of the story. Not that you get tires with them, but that the wheel-tire system is designed around the Road UST standard. If you’ve been following along on the “Road Tubeless” story, there’s actually very little standardization or agreement between wheel and tire manufacturers. Mavic led the development of a UST standard for mountain bikes back in the day, and they’ve done it again for road. This means, should you find “UST” on any road tires or rims, that you know they adhere to a specific set of measurements for interior rim shapes, heights and dimensions. For tires, it means their bead shape is designed to fit that rim shape securely. We’ll be posting a much more in depth story on Road UST soon, but the fact that these are “UST” is a step in the right direction for standardizing Road Tubeless.

Mavic’s had their Yksion Pro UST tires in the line for a while. Because they’re UST, the fit is snug and purposefully matched to the rims. They say it takes just 30g of sealant to protect against punctures and leaks. The tires are made for them by Hutchinson, but are their own design and compound to bring rolling resistance to a minimum. Weight is 260g each for the 700×25.

A new My Mavic app will have personalized tire pressure recommendations based on how you ride, your weight and the bike weight, weather conditions, and tire and rim size. They say it may give you a lower than expected tire pressure, but that most people come away happy with the recommendation.

The new Mavic Cosmic Ultimate UST will be sold as a wheel/tire system. Retail price is $4,250 (€3,500), available in a few months in January 2019. Stay tuned for first impressions and other new rider gear from Mavic.