In the world of high end bicycles, there’s typically a huge gap between stock, mass production bikes and the one-off custom bikes made by a single builder. Italian startup Exept is offering something in between, letting you choose from set options and shapes, but still get full custom geometry informed by reams of data to help you get the right fit. The result is a custom carbon monocoque bike, purposed built for you and your drivetrain, all hand made in Italy. We covered their launch announcement and showed a bit about their build process, now we’ve got more details on how their fit system works and the options available.

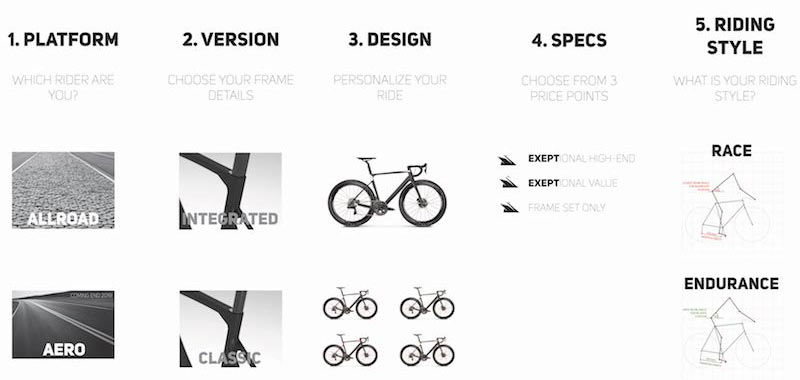

The process starts by choosing the type of bike you want. As of this post, only the All Road model is available, the Aero frame comes later this year. Then you work through the other options, building your bike to suit your riding style and preferences. Step 4 is when you pick the component group, drivetrain and wheels to suit your budget, but they’ll all be disc brakes. They’re not making a rim brake version.

You can create an account and save your progress, so you can always come back to it. The real cool feature is that you can input your body measurements (you’ll need a friend to help measure, or get a professional fit done) and it will show you your ideal frame geometry spec. It’ll even flag you if a number is too far out of range so you can go back and double check your measurements. Here’s what all the options look like, and how they came up with their geometry recommendations…

The All Road model looks like a modern road bike. It’ll have 35mm of space for the tires at the fork and stays, so they recommend a max 30mm (measured, actual) wide tire. It’s not a gravel bike, but that is a model they’re considering for the future.

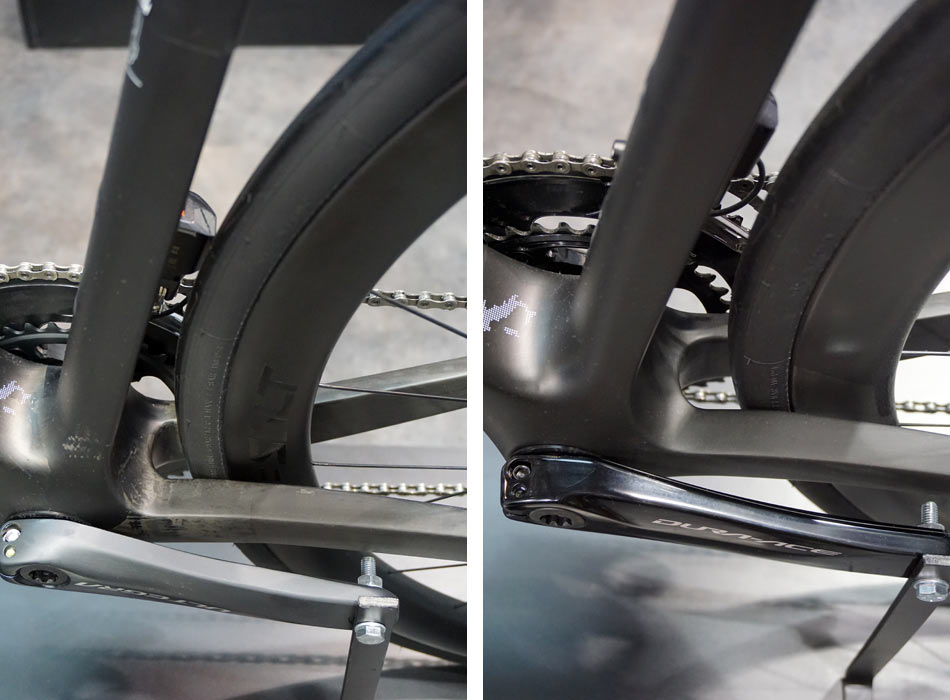

Regardless of your other choices, you’ll get a pressfit BB with rectangular chainstays and a wide bottom bracket shell to maximize power transfer.

And thru axles front and rear. Note the lack of holes in the back? That’s because this show bike was made specifically for SRAM Red eTap.

When it’s all said and done, your seat tube will be marked with the stack, reach and actual frame weight of your personal frame. We’ll be visiting their factory this fall and show more detail on their process then, but the short of it is this: Traditional monocoque bikes are made in fixed molds. Exept uses flexible but firm silicone molds on the inside, with adjustable metal molds on the outside. Within a reasonable range, they can adjust the metal molds to fit your geometry numbers, then fix everything in place so that the construction mimics a normal monocoque frame.

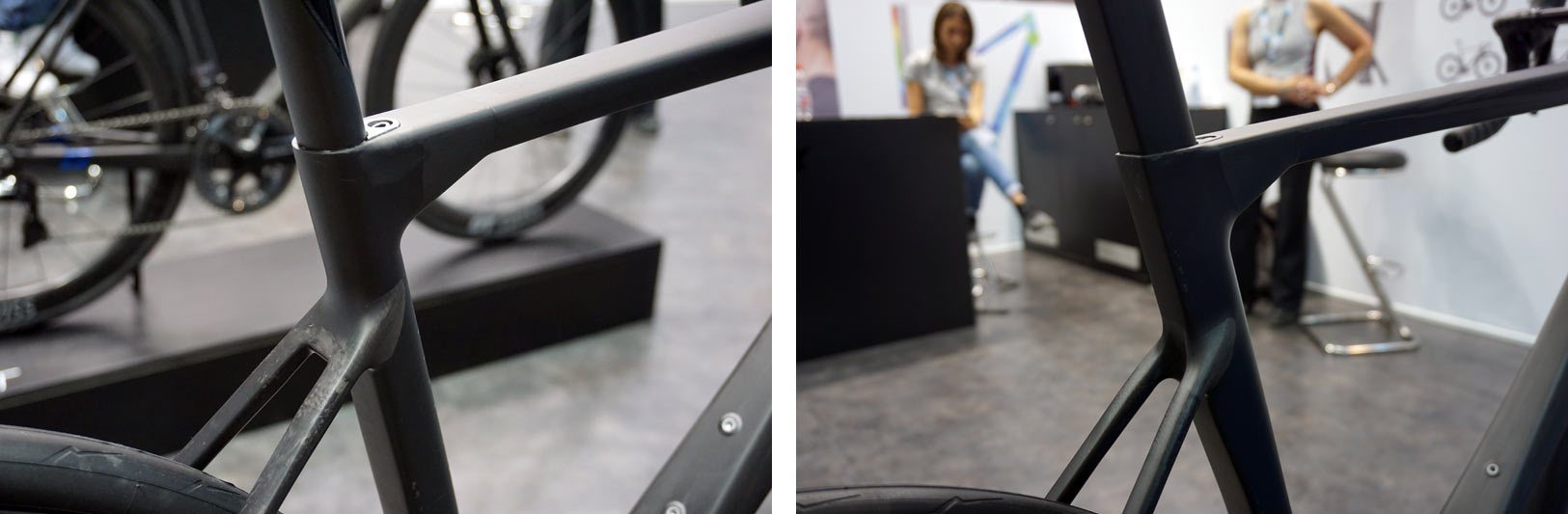

Next, you get to choose if you want the Integrated frame or Classic. Above is the Integrated version, which slams the stem and includes the Ursus handlebar/stem unit. This is the cleanest looking option as that system hides the cables and hoses by running them through the stem and directly into the frame. This way, they can remove the holes from the headtube area.

The Integrated model has a thinner downtube, so there’s slightly less torsional stiffness, and it’s a bit heavier. But it does look better, so it depends on what you’re after. The Classic model (on left) uses a traditional headtube, headset and stem and will generally be about 5% lighter than the Integrated.

The Classic model (left) uses a traditional round seatpost, while the Integrated (right) gets a different seat tube and custom seatpost with a flat back so it has less aft flex.

The last step before inputting your measurements is choosing between Race or Endurance geometry. Race frames (shown on the left) have 410mm chainstays, which is as short as they can make them and still have everything fall within recommended chainline/distance guidelines for good shifting. work with disc brakes, 410mm keeps chain line ok. Chainstays are 10mm longer for Endurance frames (on right).

Which drivetrain group you choose will dictate some of the frame features. Pick eTap and you’ll get an extra water bottle boss (right). Choose one of the other electronic groups and you’ll get an integrated junction box holder (left). Or just have them add a dummy space for it if you think you’ll upgrade to a wired electronic drivetrain in the future (center).

Cockpit choices affect the frame, too. Pick the Shimano Pro bar and stem and you’ll get a little more integration than if you choose the ENVE bar and stem, which have no channels for hiding the cables and hoses.

How Exept Determines Frame Geometry

The engineers and founders used Zedler frame stiffness results from 800 different frames over the past few years to get a baseline for desired stiffness at key points in the frame. That let them build a computer model and test layups and materials virtually. Using aerospace simulation tools, they created virtual layups and simulated stiffness tests via FEA until they got the frame the way they wanted. Then they built real test frames and compared the results to get their data correlated and validated. Now, when they need to make adjustments virtually to tune the layup for a specific customer, they’re confident that the results will match the end product.

Once they have your measurements, they work backwards to get stack and reach, then the head angle and trail and rake. They measured me while at the show, plopped in the numbers, and we ended up within a few millimeters of most of the road bikes I ride, which is impressive. If you really want something different, you can force change a number or discuss options with them, but their numbers are based on what’s been proven to have good handling and ride characteristics out in the real world. As for their ability to translate that through the layup, we’ll find out later this year. They’re building a bike for us to test long term, to be delivered this fall. Stay tuned…