Ceramic coated aluminum bicycle rims have been around for decades, offering higher friction and durability for improved braking performance. Then disc brakes took over, offering vastly superior performance. But what if you combined the two? That’s one of the trends we saw at Taipei Cycle Show, and here are two brands with a variety of clever disc brake upgrades…

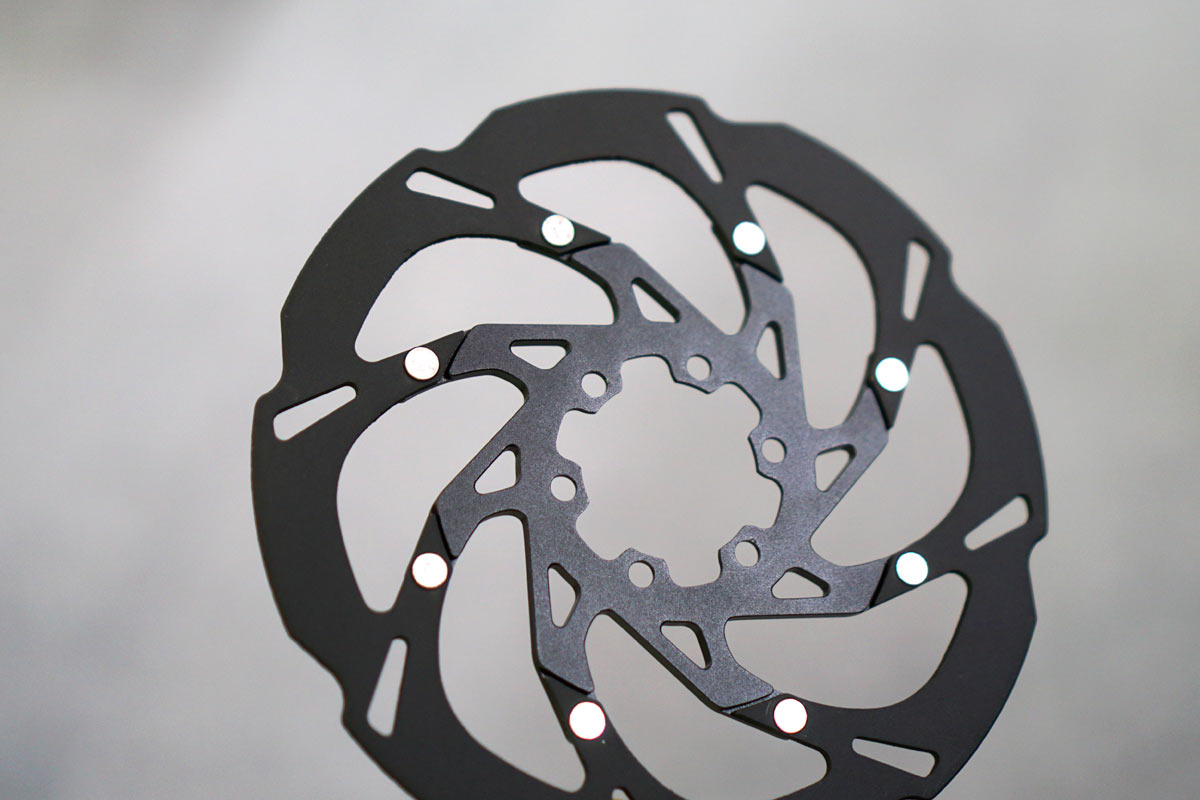

Above is the ceramic coated aluminum disc brake rotor from HSC (Huang Chieh Metal), which uses a bit of venting on the braking surface and an 8-arm structure to maximize stiffness. They use a MAO (Mico Arc Oxidation process to bond the ceramic material to the aluminum, which they developed to be able to offer these at a reasonable cost.

But why do this? Aluminum is not only lighter than the typical steel rotor, it also dissipates heat better. But, it makes a lousy braking surface. Adding the ceramic coating gives it much more friction, increases its durability, and according to their testing reduces the amount of force you need to apply at the lever by about half to accomplish the same stopping distance in dry conditions. Wet weather performance is also supposedly better.

HCM’s ceramic-alloy rotors come in at a claimed weight of 95g. We like the potential of this proven rim brake technology coming to rotors that are 2/3 or less the weight of a traditional steel rotor.

HCM also makes multi-material rotors, sandwiching an aluminum core between stainless steel braking surfaces. This new version exposes more of the alloy inside the center, helping to cool it even faster. It’s similar to Shimano’s ICE rotor tech, but without the giant fins.

Brakco Ceramic Rotors & Carbon Pads

Brakco was another brand showing off ceramic alloy rotors, but with a few tweaks. Their rotors have a nice rounded edge that should keep the UCI happy, and a slotted design to shed crud. They’re also offering it with either a full 7075 alloy carrier or a combo carbon/alloy carrier. Claimed weights are as low as 49g (140mm) and 72g (160mm) for the alloy carrier, and drop even more for the carbon/alloy version…45g (140mm) and 68g (160mm)!

Both Brakco and HCM rotors require special brake pads to work with these MAO rotors.

Brakco also had these carbon fiber backed brake pads for the usual Shimano and SRAM calipers, with various pad materials on offer. The benefit? Much less heat transmission from pad to fluid. And bragging rights. Because carbon. The trick with these? They’re mostly an OEM manufacturer, so you’ll have to hope another brand picks these up. Or start importing them yourself and slap your own label on them.