From the over-the-top materials selection to the precision assembly and incredible attention to detail, this tour will both educate and entertain. And it should help explain why Silca’s pumps and tools cost what they do. Throughout the video you’ll see their ultralight titanium water bottle cage go from raw tube stock to a finished product. Which is awesome. But just wait until you see how they test them!

Watch the video for the complete tour, and here are select photos of their heritage parts, modern versions and the facility…

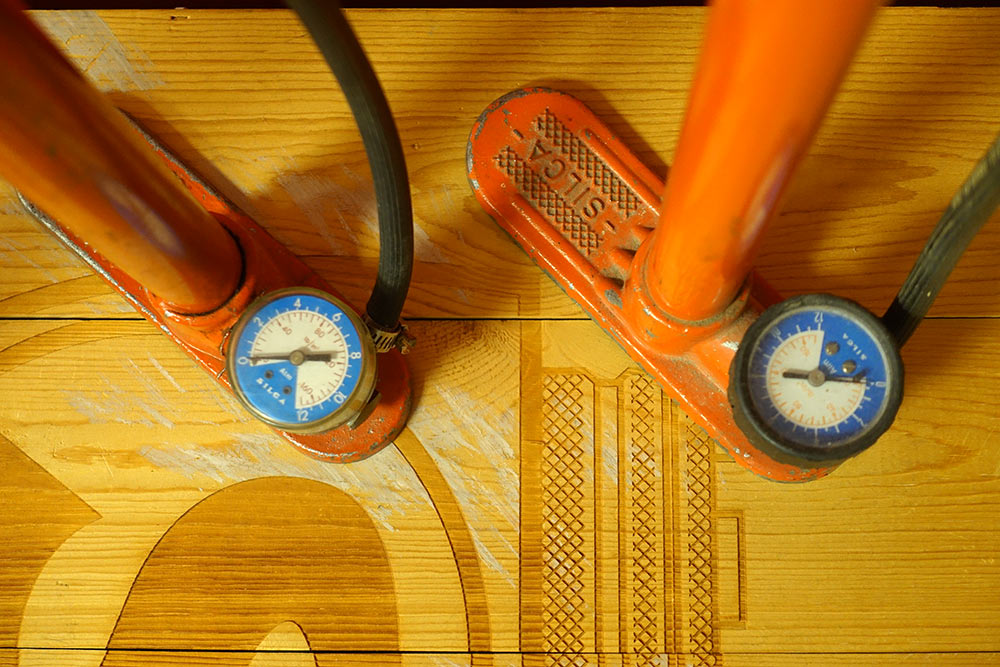

Vintage Silca floor pumps

Josh’s favorite blast from the past is this 1952 Silca pump with cast iron base and original wood handle.

The best part? It still works (it just needs a hose).

The collection shown at the top of the post and directly above includes one of the original Superpista Ultimates, which had a celluloid handle (brown, larger). The frame pump shown here has a full celluloid body. Wood and metal were harder to come by or used to feed the war machine during major parts of Silca’s early years, so they had to find alternate materials.

The pump on top of the box was Josh’s first personal Silca purchase, and it’s still original. And it still works.

Compare that to the current model and we can all be grateful for materials advances…but they kept the original features that matter, like a leather plunger.

Modern Silca pumps

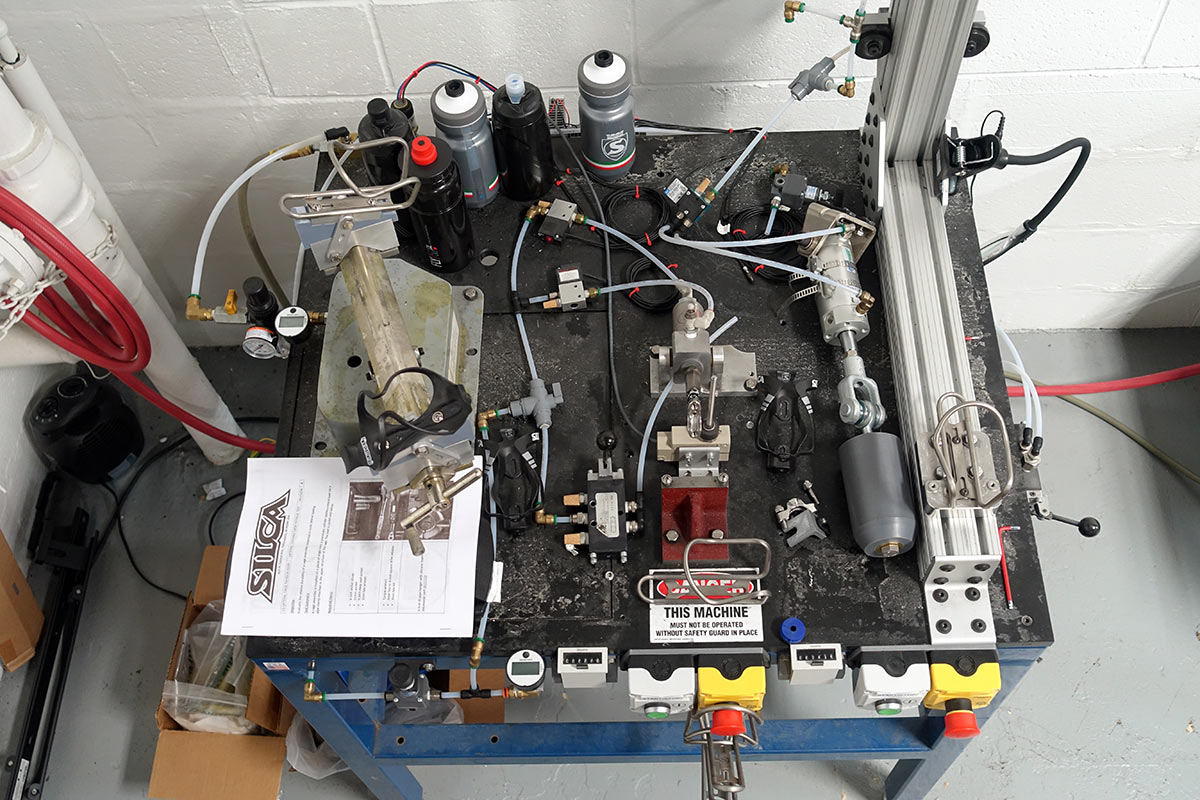

The current crop of Pista Ultimate pumps use tons of parts from all over the world. Why? Because they want only the best materials and components inside their pumps, like waxed rose wood from Indonesia…

…and 10,000psi Formula 1 brake hose with a custom swiveling head.

The Pocket Impero mini pump is smaller, but gets just as much attention to detail with U.S.-made alloy tubing sourced near their Indianapolis, IN, headquarters.

Titanium cages are about more than bottles

They’re about the future of specialty manufacturing. Are computer controlled, double-pass laser welders necessary for making ti bottle cages? No. Are they a safety net against whatever may happen in the future? Absolutely. Because very few people and places can do this kind of welding.

And with more and more of their suppliers having to limit manufacturing for Silca because government military contracts are buying up all of their time and materials, being able to do something that no one else can is a big benefit. And it means they have options. It also means you get the Sicuro ti water bottle cage.

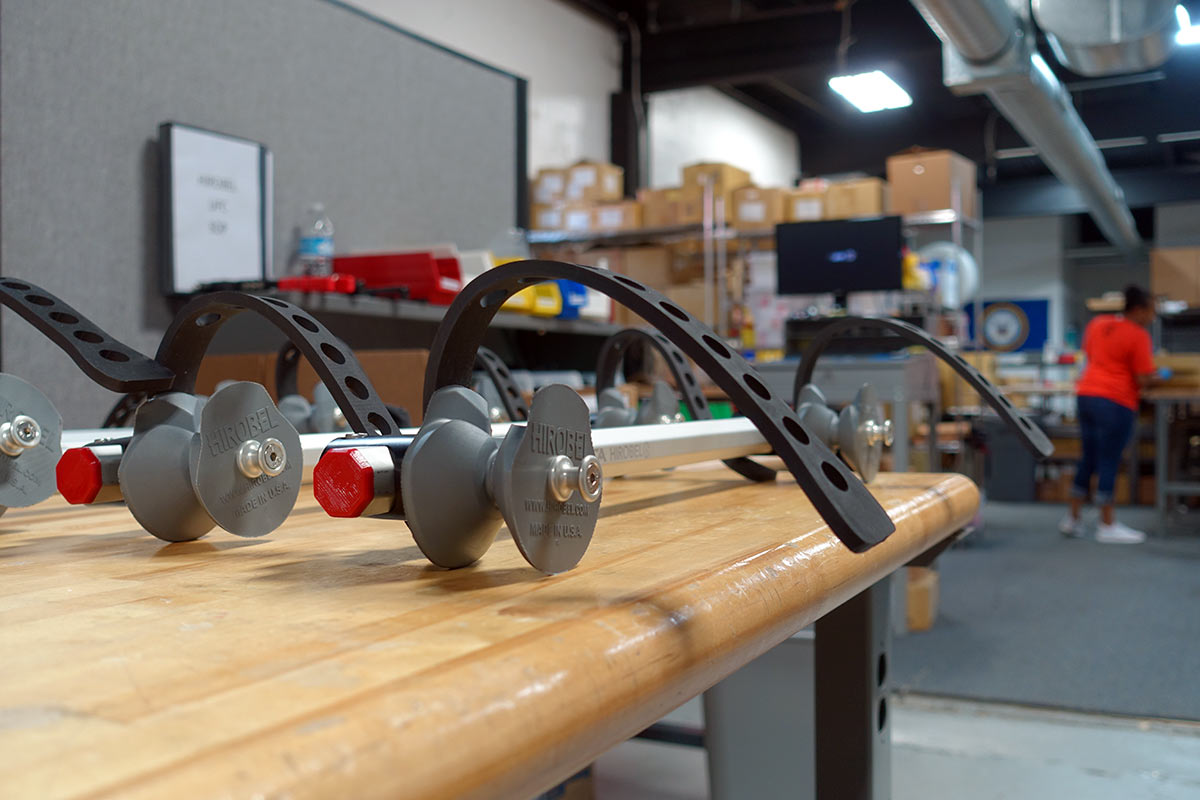

How many small (or large, for that matter) manufacturers have THREE dedicated water bottle cage testing machines?

If you watch the video for nothing else, it’s worth seeing the process they take to cut, bend, weld and test their titanium bottle cages. It tells you everything you need to know about their attention to detail.

Other tools and toys

Silca’s T-handle hex set uses S2 tool steel machined to precise tolerances that take into account the protective chrome coating when measuring their designs. They’re as close as you can get to perfect. Now you only need to worry about the bolts’ tolerances. Check out this video of Josh explaining all that.

Silca recently acquired Hirobel to help get its production up to speed. Based on Josh’s comments about bike brands seeking better ways to design a seatpost, we have a feeling these might become standard equipment at your local shop (and your garage) within a decade. (So, what did Josh say? You’ll have to watch the video, it’s just one of so many nuggets buried in his tour!)

Huge thanks to Josh Poertner for showing us around!