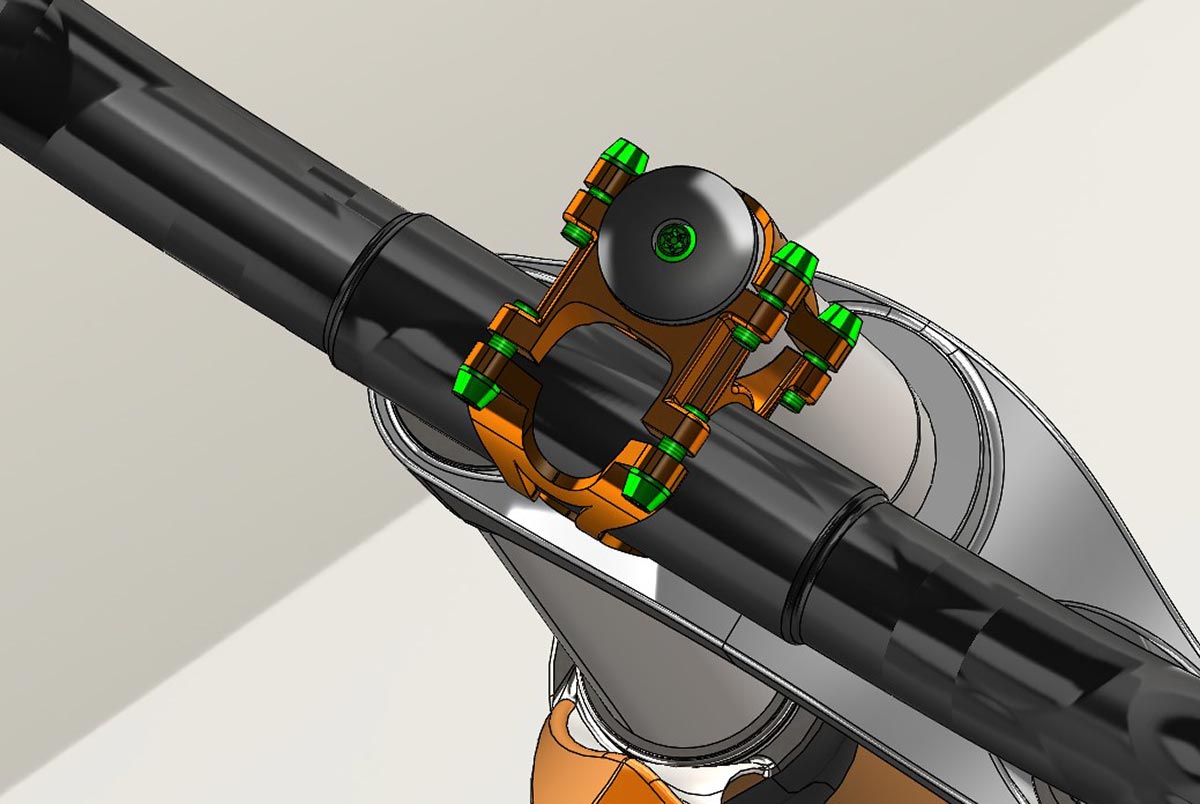

Gabriele Boasso, Mechanical Designer and founder of Components Bike Design, has revealed images of their concept stem with three piece design. Merely a concept with 3D printed prototypes for now, this unusual looking stem takes a different approach to clamping the steerer tube. Let’s take a closer look to figure out what’s going on here.

Components Bike Design Concept Stem

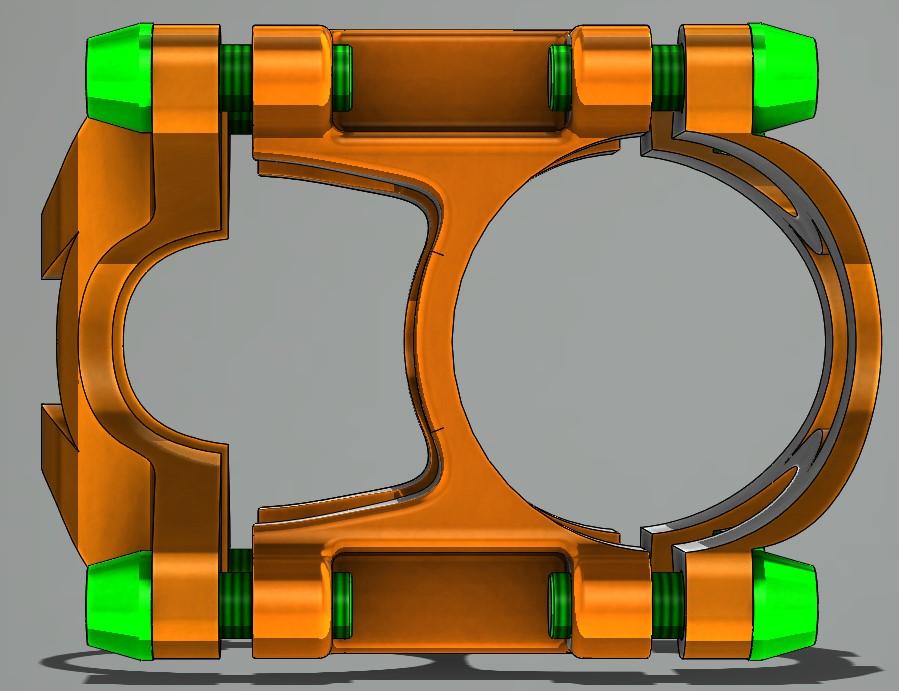

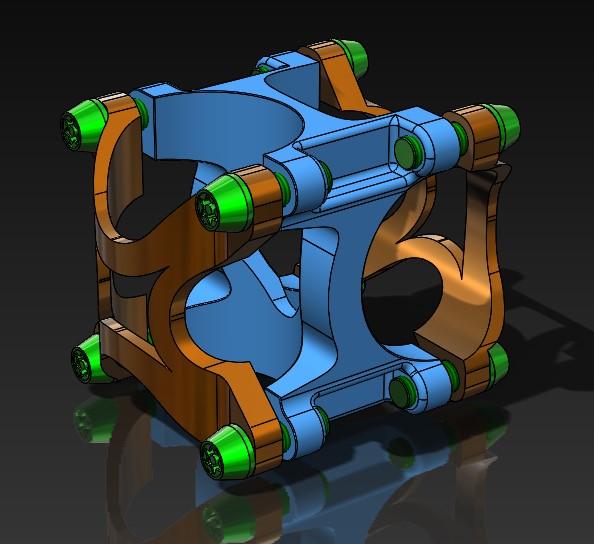

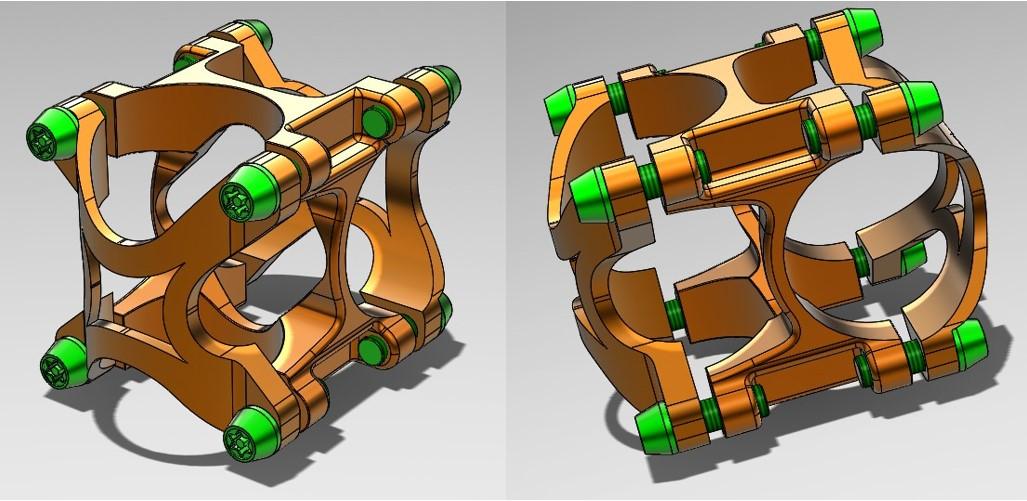

The three piece stem is composed of a face plate, a central piece that cups both the handlebar and the steerer tube, and a second “face plate” style piece that bolts into the central piece to clamp the steerer.

The intention with this modular design is apparently to allow riders to swap out the central piece when they want to change the reach, rather than swapping to a different stem entirely.

Before we discuss function, my first thoughts are about how convenient this might actually be. First of all, to swap out the central piece, you’ll need to unscrew eight bolts, as opposed to the 6 bolts you need to unscrew when changing a traditional stem.

The reach of the prototype stem shown here is 32mm. Though most brands aimed at trail and enduro riding offer just a 35mm or 50mm option, there are a small number of brands out there collectively offering just about every length in between. Plus, a few offer even shorter options such as the Pacenti P-Dent, though this is solely compatible their indented handlebar.

The design pictured has us wondering whether they are planning on offering a multitude of central pieces of differing lengths, in order to allow riders to select the exact reach that is best for them and their bike? Anyone for trialing reach in 1mm increments? Given the number of options already offered on the market, this would seem unlikely.

The 4 bolts connecting the central piece to the rear plate are oriented in the direction of the bike’s travel – forwards, instead of across the ways like we see on traditional stems. This calls into question how strong the system is laterally in comparison to a traditional stem. Will those bolts experience greater forces when cornering? Will they be strong enough to withstand said forces? Will the headset hold its adjustment without full contact surfaces around the steerer tube clamp? I’m no mechanical engineer so I’ll reserve judgement.

Details are thin on the ground at this stage. Gabriele’s plan now is to optimize the design from a structural point of view and to make a titanium model. It is undecided as to whether the stem will be made from aluminium or titanium, but the bolts will be titanium M5.

It is said that the front and rear plates will be customizable with the rider’s team logo or a specific sponsor, for example. Prototypes thus far have been made using ABS 3D printing.

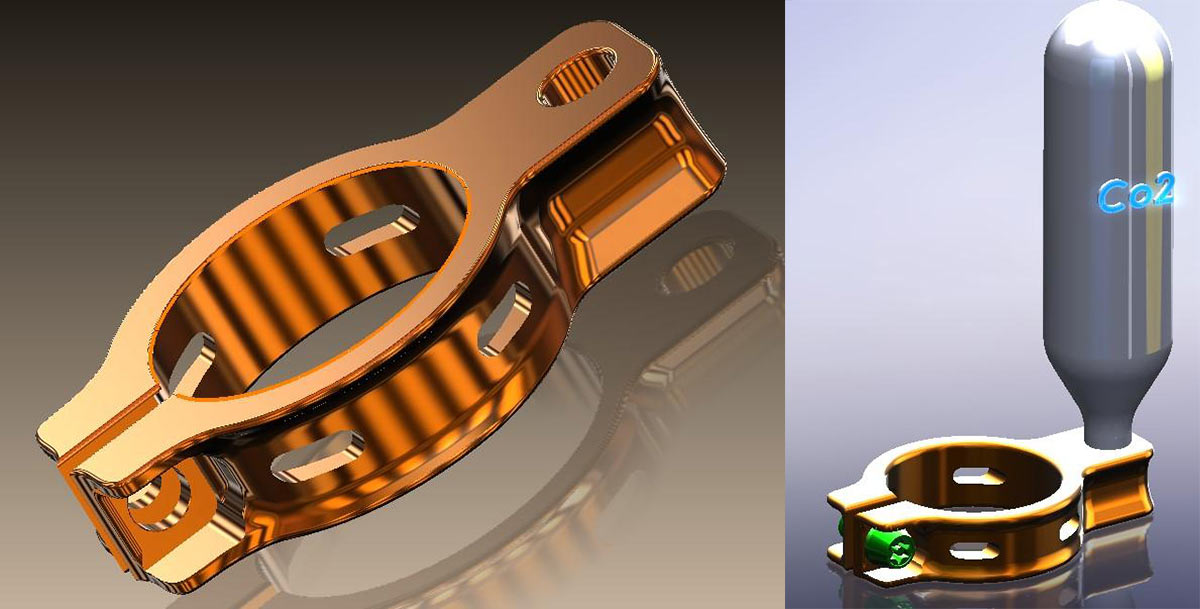

Seatpost clamp with CO2 storage

Gabriele Boasso’s second concept product for cycling is a seatpost clamp that can carry a CO2 canister. It’s good to see product designers innovating in the space of on-bike storage. It’s a great freedom to be able to ride packless, so the more trailside essentials I can fit on my bike the better.

The clamp is the traditional design with one bolt clamping the aluminium piece around the top of the seat tube. The difference here is the addition of a thread to accommodate a CO2 canister.

I carry a spare CO2 canister on a frame strap, and I tape the threads to keep them clean for ease of use when I need it quickly. This seat clamp storage design seems like it would hold a canister securely and keep the threads clean at the same time. That said, i’m not convinced that everyone would be happy to store pressurized gas underneath their saddle.

For more on Gabriele’s designs, you can follow ComponetsBikeDesign on LinkedIn here.