Prepared specifically for Spanish rider Mikel Landa’s Merida TT bike at this year’s Tour de France, Muc-Off is getting into the upgrade parts business with their new oversize derailleur pulley kit. Because, when you can’t make any more of a (legal) chemical advantage, it’s time to go mechanical…

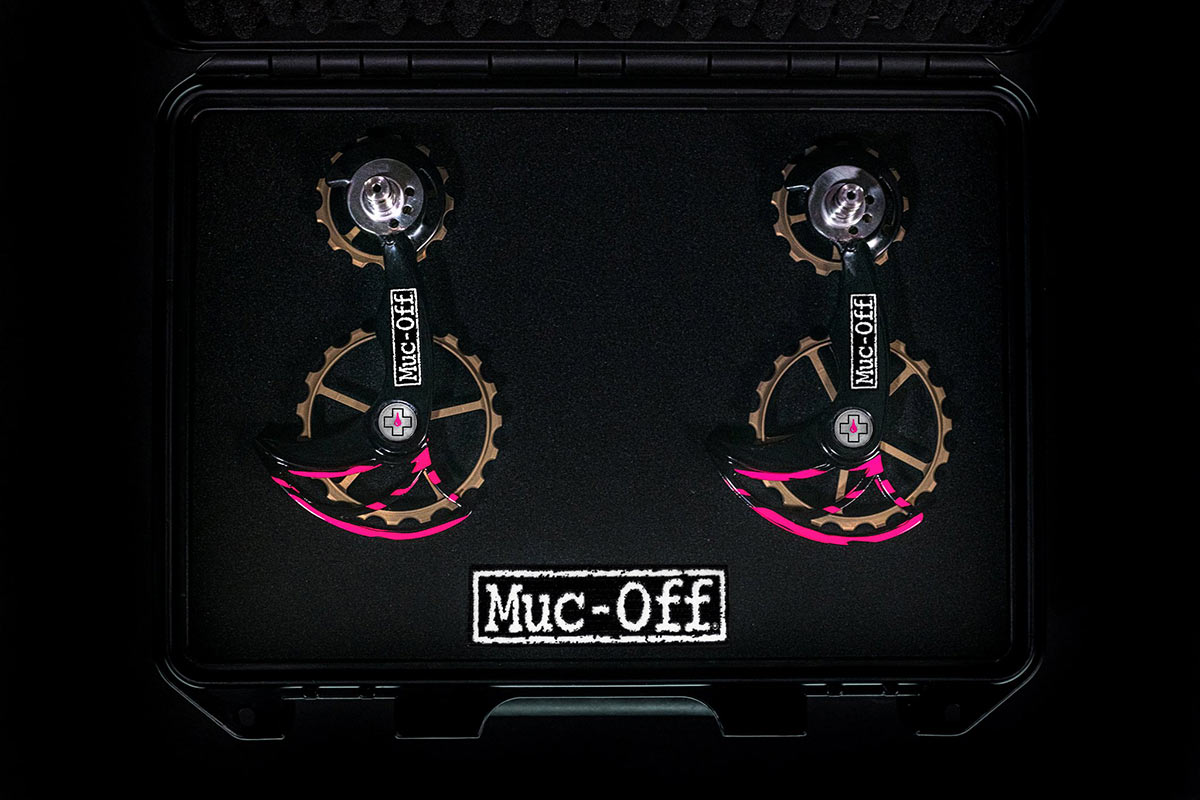

Here’s the tech details: It’s called L.O.P.S., for Lightweight Oversized Precision Shifting. It uses a titanium cage body that they say is both lighter and stiffer than its competitors. The alloy pulleys are coated with a low-friction finish, as are the bearings.

The device was created as part of Muc-Off’s “Project Landa”, with the goal of developing an oversized pulley wheel system alongside its fastest ever lubricant for Team Bahrain McLaren’s Tour de France leader, Mikel Landa.

Landa is a Grand Tour stage winner and widely regarded as one of the world’s best climbers (Muc-Off’s words), and as of this post he’s going to start Stage 20’s TT in 5th overall. At more than 3 minutes down from yellow, he’ll need every incremental advantage he can get.

Here’s how Muc-Off explains it:

L.O.P.S is an oversized pulley wheel system developed by Muc-Off’s scientists and engineers in partnership with McLaren. Comparative tests conducted using the sophisticated equipment in the new, leading-edge laboratory at the brand’s headquarters in Poole, Dorset, confirmed it as the lightest and stiffest of any of those selected from leading competitors.

The titanium body is created using a sophisticated additive manufacturing process. The pulley wheels (13t upper, 19t lower) are made from aerospace grade aluminium and finished with a supremely efficient coating that delivers friction coefficients over three times lower than hard anodised equivalents.

The bearings were manufactured to aerospace level specification. The size of the bearing used was optimised for the number of rolling elements and application speed to help reduce frictional losses. Ceramic rolling elements are lubricated with a special synthetic hydrocarbon to further reduce the coefficient of friction and tighter radial and axial tolerances improve shift accuracy.

Optimised specifically for the individual time-trial, the final piece of the puzzle to help maximise performance, was the lower sealing requirements, which led to further bearing drag reductions and to incorporate highly compatible material expansion rates.

That last part’s interesting, using minimal seals to reduce friction and drag. Combine that with a specific new lube and chain treatment, and you’re looking at a no-expense-spared attempt to give Landa every possible advantage.

Stay tuned for their promo video on this to go live at 12:55pm EDT.

No word on commercial availability, but you can get an extremely deep tech dive into this products development on their website, and register your interest in buying one.