For years developing bikes for other brands at manufacturers in Taiwan before they more recently set out on their own, ARC8 is taking back more control with Faserwerk – a project to bring their own carbon construction completely in-house. Starting with carbon handlebars & seatposts, ARC8-made cockpits are just a stepping stone towards bike production, and even moving production to Europe…

ARC8 Faserwerk in-house carbon manufacturing in Taiwan

Founding partner Jonas Mueller of ARC8 has been engineering and building carbon bikes himself since 18. So after working for other big manufacturers in Taiwan and then starting his own bike company there, he recently got the opportunity to buy ARC8’s own production facility in Taiwan. With an eye on having better control over their bikes, the new ARC8 Faserwerk project closes the loop for Mueller & his team, from design through construction, while taking advantage of Taiwanese carbon expertise.

For now Faserwerk is limited to producing carbon handlebars and seatposts. But ARC8 isn’t shy about suggesting that the entire point of the project is to start producing their own framesets in-house too. And just as important to note, originally from Switzerland, Mueller says that the ultimate goal is to transition their carbon manufacturing back to Europe.

Tech Talk: What’s unique about ARC8 bars & posts?

ARC8 says that the surprisingly rare combination of one engineering team both designing & manufacturing components means they can better take advantage of the strengths (& limitations) of their chosen manufacturing techniques, designing buildable components from the beginning.

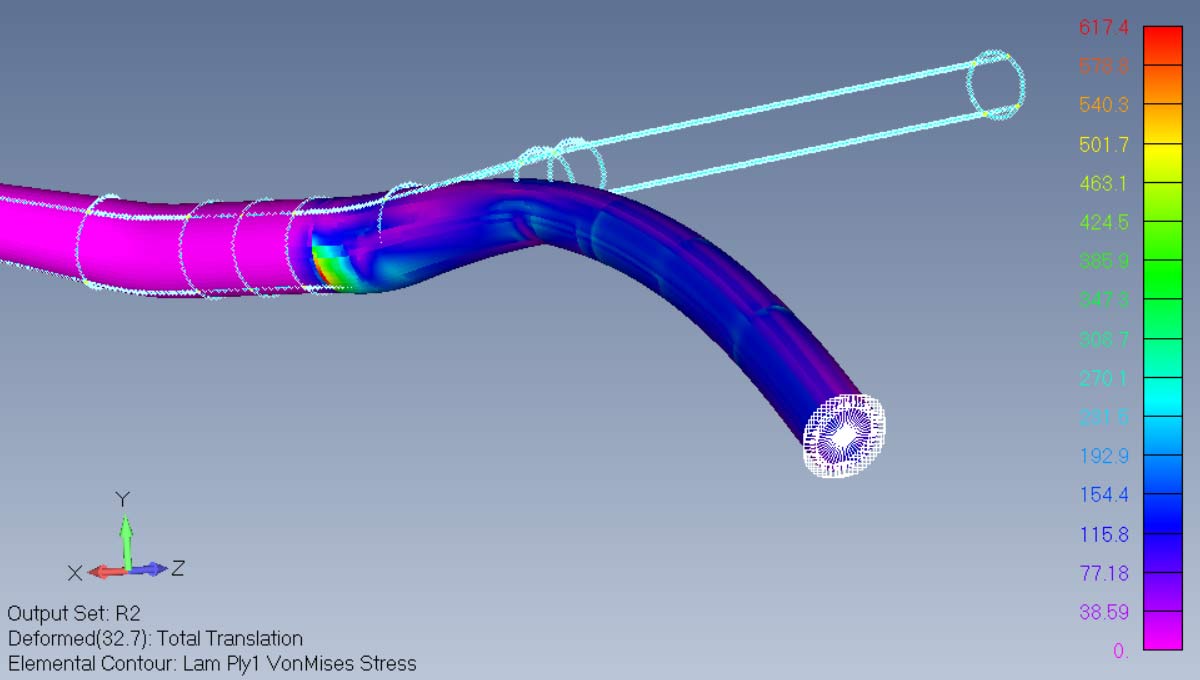

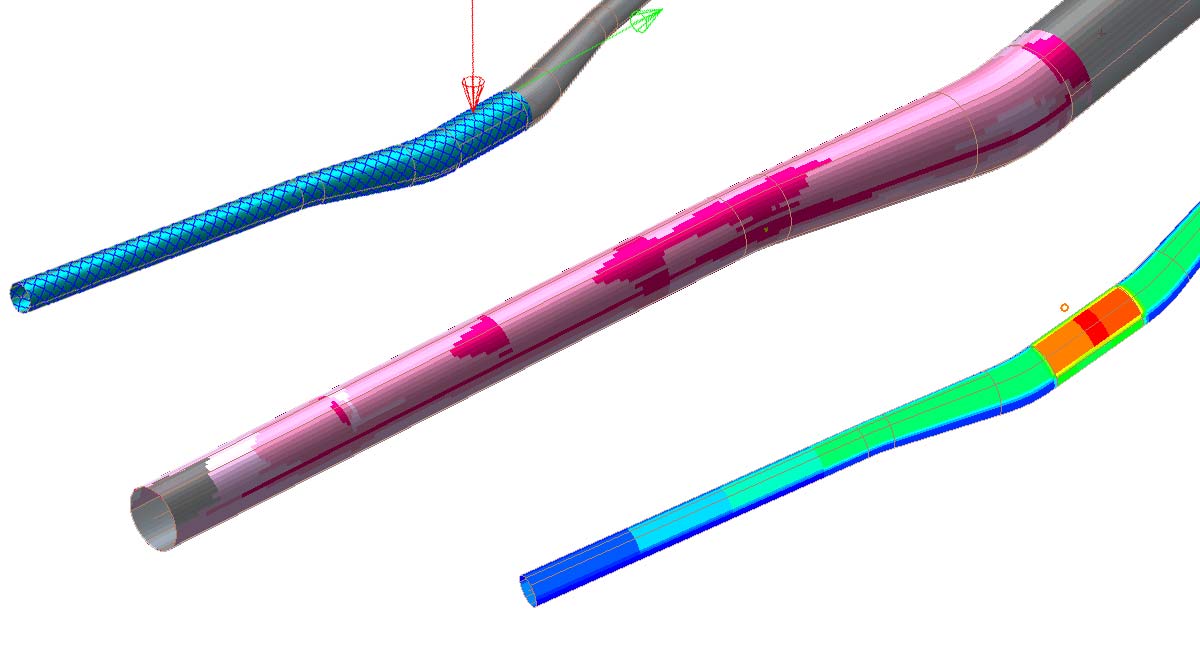

Mueller says that using leading computer simulated FEA tools to both design & virtually test the components before thinking about material allows ARC8 to define performance characteristics in more detail.

Laminate Tools, Femap & FEA

Laminate Tools, Femap & FEAThen, Formula 1 derived layup simulation tools allow the engineers to map plies of carbon directly over the virtual model until they get the exact localized blend of stiffness & flexibility as intended. Going back-and-forth from Femap to Laminate Tools to FEA is said to give a more holistic view on the design than more conventional approaches, and leads to lighter weight & better performance with less trial & error needed.

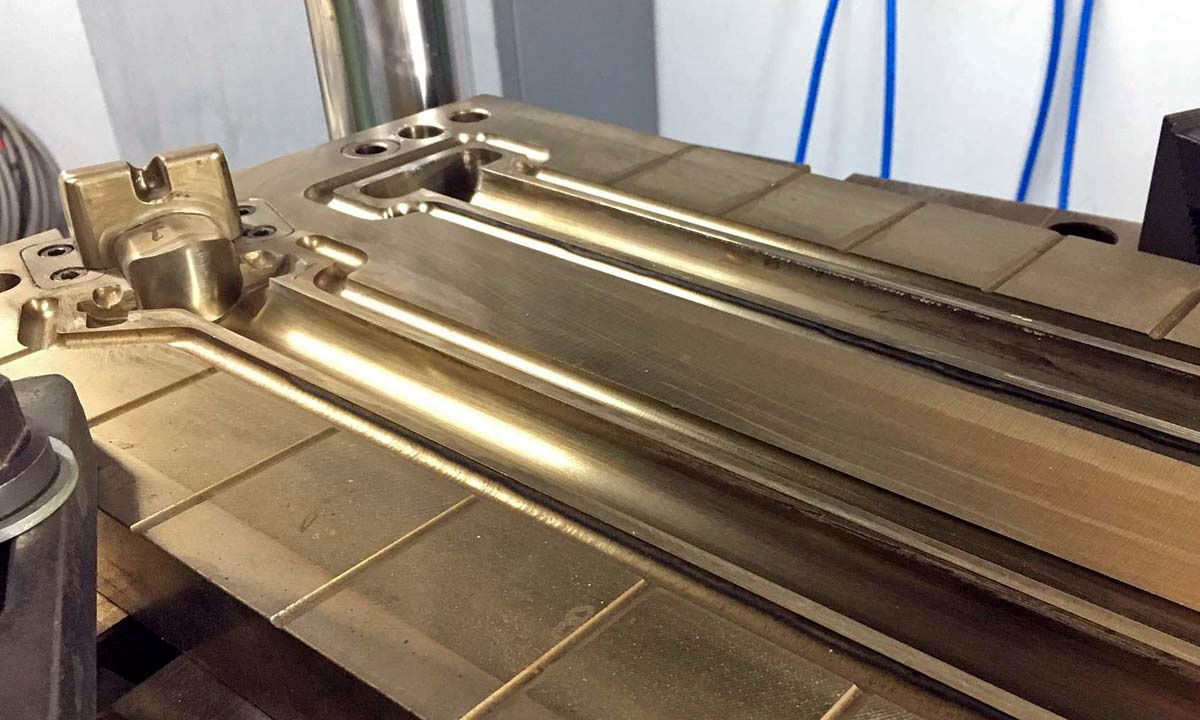

ARC8 Faserwerk effectively relies on just a few carbon manufacturing techniques in the end. CPMC (compression molding compound) enables them to squeeze carbon into complex solid parts efficiently under high pressure (up to1450psi/100bar), like the cradle & guts for your saddle rails.

To create hollow but complex shapes, like a seatpost with a one-piece head – 3D Forging essentially combines CPMC pressure techniques on one end of a mold.

At the same time, the rest uses normal long fiber carbon plies wrapped around a conventional bladder or mandrel that can be removed after the part is formed as a single piece – cured at one time for max strength.

Also when you look at handlebars, ARC8 was never really satisfied with comfort mostly being left out of the equation in deference to stiffness & light weight. So their bars were developed to take advantage of a viscoelastic layer in between stiff carbon fibers to damp vibration. Even stiff bars flex under impacts, so the ARC8 bar aims to damp the resulting vibrations, so the bar returns back to center faster for improved control & rider comfort.

ARC8 Faserwerk – Actual products: MTB bars & posts

While that’s a lot of tech about manufacturing, for now there are just two real ARC8 Faserwerk products (although we’re sure that will be expanding!)

One is the mountain bike handle bar – the Faserwerk Rockstock. A 800mm wide, 20mm rise all-mountain bike bar, the $199 / 199€ Rockstock is meant to be light AND to significantly reduce fatigue thanks to its viscoelastic damping layer inside. The 189g bar features 9° backsweep, 6° upsweep, and a 31.8mm clamping area.

The other is the Faserwerk Wuthocker, a two-bolt 3D forged carbon zero offset seatpost. The $249 / 249€ one-piece carbon post is available in a single 27.2mm diameter, 400mm long, with a claimed 188g weight.

Both Rockstock bar & Wuthocker post are available now direct from ARC8, and we’ll have to wait to see what other Faserwerk products come together over time.