Shimano’s 12-speed mountain bike group lineup is finally complete, so how do they all compare? What’s the real differences between Deore, SLX, XT and XTR? Which parts are worth upgrading? Why is one better than the other? How do the actual weights compare?

Having literally travelled around the world to attend the XTR launch in Japan, and to Bellingham for the XT/SLX launch, I was surprised at how much more there was to learn.

This video and post is the result of nearly a week’s worth of research, hours on the phone with Shimano’s technical reps, and tons of back and forth email. It is the reference on what separates Deore from SLX, XT from XTR; and how Dynamic Chain Engagement and HyperGlide+ work.

Yep, it’s a long video. But if you’ve ever wondered what really makes one component better than the other, it’s all explained right here…

Shimano 12-Speed MTB Group Comparison

Across all of the parts, you’ll notice four main things as you move up the line:

- Appearance: Finishes differ slightly and are fancier on higher end parts.

- Tolerances: The top end parts have tighter tolerances, getting better and better as you go up the line. The fit and finish of the top end groups is going to look and feel more premium, and is measurably better.

- Weight: Things get lighter as you go up the line.

- Durability: All of Shimano’s parts are durable, but the materials used in XT and XTR are less prone to wear. And, generally, anytime the tolerances are more exact, things tend to develop less play and last longer.

It’s worth noting that more pieces and parts on the high end components are made in Japan, in Shimano’s own factory, where higher QC standards apply than their other factories in other countries. Even the weight range has a tighter tolerance, which is why you won’t see a claimed published weight for Deore 6100 parts, but you will for the rest.

This also explains why XTR has a 3-year warranty while the other groups have two years.

Fun Fact: Technically, XT is “Deore XT”, and should be referred to as such if you ever find yourself in the hallowed halls of Shimano. But for brevity, we’re calling it by it’s street name, XT.

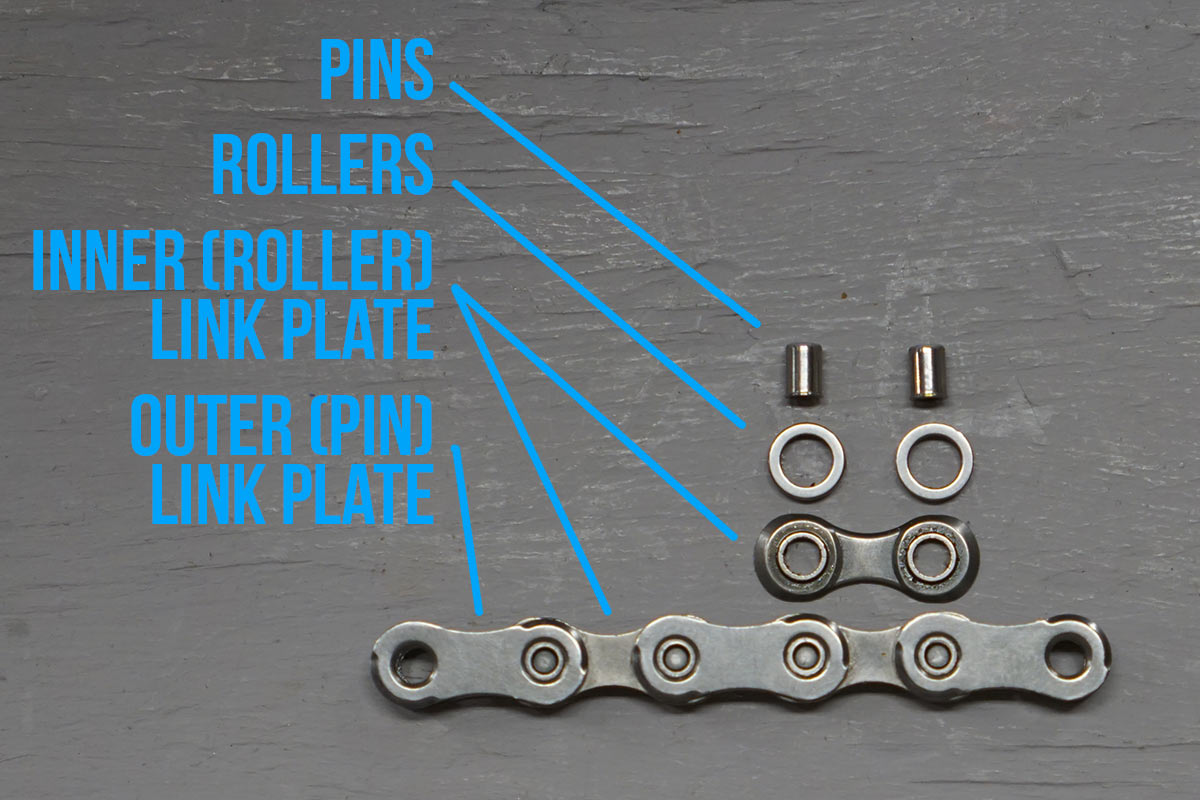

Shimano 12-Speed Chain Comparison

We’re starting with chains because the technologies and designs used here help make things like DCE and HyperGlide+ possible. So, understanding their design helps us understand why Shimano’s drivetrains work so well. And their select use of two materials – SIL-TEC and Chromizing – show how they differentiate otherwise very similar looking parts. So, a quick explanation of those:

- SIL-TEC: an advanced plating process that bonds fluorine particles to the metal to create a long lasting, ultra low friction surface. It also helps reduce noise considerably. Shimano says Fluorine is a highly reactive material, so once it comes in contact the metal on the chain, it reacts vigorously and stays bonded and stops reacting with other materials. Meaning, it’s less likely to shed molecules as it slides over a gear’s teeth. And that, Shimano says, is a major part of friction – molecules reacting with each other between surfaces. So, the less things react with each other, the less friction you’ll have.

- Chromizing: Chromium is diffused into the the metal to make it harder, so it’ll last longer. They’ve been using it for years, and it makes its way to all four 12-speed chains, but in different areas.

Used together, you get both benefits – more durability and less friction. But, Chromizing is a more expensive process, so in some cases, you’ll only see SIL-TEC being used, or only Chromizing. And sometimes both.

All four of these chains use the same plate shaping, and start with the same high quality steel chain. It’s the finishes that separate them. Here’s the breakdown:

Deore CN-M6100 Chain

- Chromizing roller link pin

- 252g

SLX CN-M7100 Chain

- SIL-TEC roller link plate

- Chromizing roller link pin

- 252g

XT CN-M8100 Chain

- No SIL-TEC

- Chromizing roller link plates and pins

- 252g

XTR CN-M9100 Chain

- SIL-TEC pin link plates and roller

- Chromizing roller link plates and pins

- Upgrades to hollow pins (saves 10g)

- 242g

Shimano 12-Speed Crank & Chainring Comparison

For the cranks, all but Deore use their Hollowtech II construction, which basically means they’re hollow forged.

All of Shimano’s Hollowtech II cranks are made in Japan. As a side note, all higher end brakes are bled in Japan, but once you get down to Deore level, they’re done in Shimano’s Malaysia factory. None of their components are actually made by a 3rd party manufacturer, Shimano makes virtually everything they sell. But not everything is made at their Sakai Intelligent Plant at their headquarters in the Osaka, Japan. They save that place for their best stuff.

Here’s how the cranksets compare:

Deore FC-M6100-1

- Forged, not hollow

- Comes with chainring pre-installed

- Color-shifting logos

- 172/178mm Q-factor options

- 789g w/ 32t ring

SLX FC-M7100-1

- Hollowtech II hollow forged arms

- 172/178/181mm Q-factor options

- 634g w/ 30t ring

- 154g lighter than Deore

XT FC-M8100-1

- Hollowtech II

- Pared down arms, but very similar to SLX

- 172/178/181mm Q-factor options

- 622g w/ 30t ring

- 12g lighter than SLX

XTR FC-M9100-1

- Hollowtech II, sort of – it’s a two-piece arm construction where top and bottom are forged separately, excess material is machined out, then they’re bonded together. Lets them remove more material to make them lighter

- Integrated attachment bolt eliminates dual pinch bolts

- Narrower 162/168/171mm Q-factor options

- 528g w/ 30t ring

- 94g lighter than XT

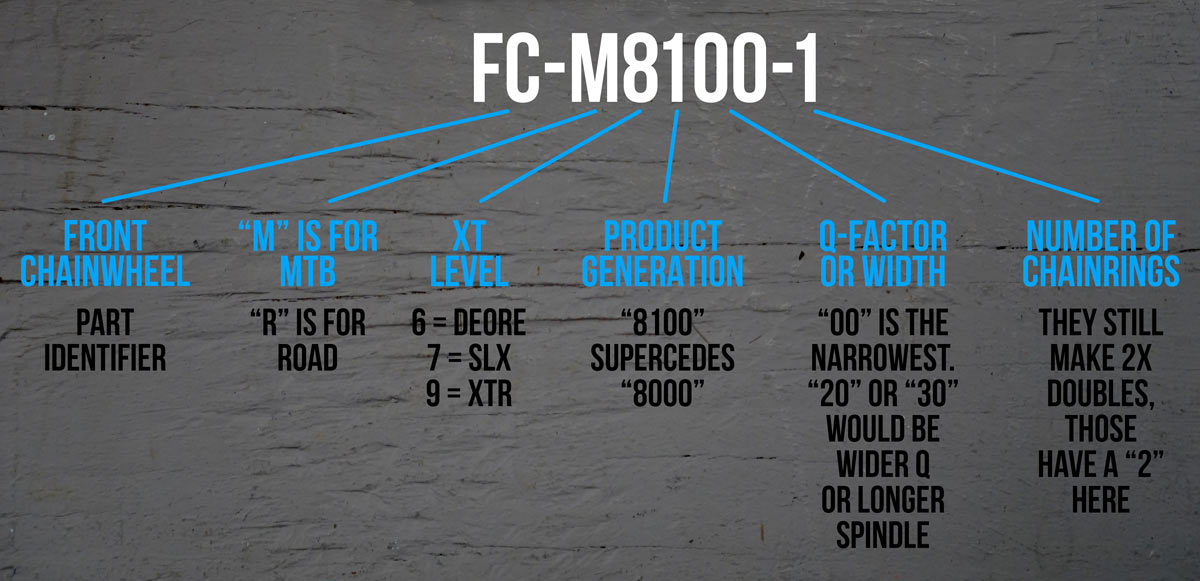

What do Shimano’s model numbers mean?

Regarding their numerical naming scheme, each number references something, helping you make sure you’re getting the right part for your build. The image above is a general breakdown based on XT, but you’d want to double check the specs before buying.

It’s worth pointing out that XT and XTR used to have RACE and TRAIL versions. They still have them, they just don’t call them “Trail” and “Race” anymore. Instead, they’re named numerically, and XTR has dramatically narrower options than the rest. If you’re considering the narrower ones, you’ll want to check to make sure they’ll clear some wider Boost or SuperBoost frame’s chainstays. If in doubt, go with a wider crankset, it’s only a few millimeters difference anyway.

What about the chainrings?

Shimano’s higher end cranks don’t have the chainrings installed. That’s because for SLX, XT and XTR, they’re sold separately.

While Deore’s chainring looks like a standard four-bolt affair, it’s not. Deore uses a more traditional looking spider, but it’s actually a direct-mount item that’s one unit. The spider is alloy, with a steel chainring permanently attached to it. So if you want to replace the chainring, you’re replacing that whole assembly. But don’t worry, they’re cheap.

SLX and XT chainrings both use an alloy carrier with steel outer teeth, which get an anodized surface treatment to improve durability. They look very similar, other than XT getting an anodized carrier where SLX is painted. The real difference is the composite middle section.

On XT, it’s a Carbon Fiber Reinforced Plastic.

But on SLX, it’s a Glass Fiber Reinforced Plastic.

Shimano tells us XT’s carbon one will be slightly stiffer, and maybe a couple grams lighter. It’s not really about the weight, though. It’s about giving it a better strength to weight ratio. And that helps explain why the XT rings cost about twice as much as SLX.

XTR is a one-piece, all-aluminum chainring with a very expensive surface treatment to bring its durability up to comparable levels as the steel chainrings on the others. So, it’s a lot lighter, but just as durable.

All 12-speed chainrings use Shimano’s Dynamic Chain Engagement+, which is their unique take on a narrow-wide design. For the best explanation/demonstration of how this works, the video shows how the wide teeth interface with the chain, and how the chain’s design prevents vibration and noise. It’s rad. I know, 29 minutes. It’s worth it.

Shimano 12-Speed Cassette Comparison

The biggest differences between Shimano’s 12-speed mountain bike cassettes are the materials used to increase durability or reduce weight.

All four use HyperGlide+, which is Shimano’s latest shifting design and it relates to the shaping that helps the chain shift more quickly and smoothly in both directions…up and down.

While they offer smaller, tighter range 10-45 cassettes for the race groups, we’re comparing the more popular 10-51 cassettes here, all of which have the same gear steps:

(2-2-2-2) (3-3) (4) (5) (6-6-6)

Shimano’s Micro Spline freehub body still uses a timing groove, meaning, one groove that’s larger than the others. This is necessary because it’s not a full one-piece cassette, so they have to make sure every cog lines up correctly with the one before it in order for the HyperGlide+ to work properly.

Fun Fact: Shimano says if you want HG+ to actually work as intended, you’ll need to use their 12-speed mountain bike chains, with all their chamfers and shaping.

One of the most interesting feature is how the smallest two cogs connect with the others.

The 10t and 12t cogs barely sit on the freehub body’s splines, if at all, and so they actually rely on these tiny grooves to lock into the the bigger cog behind it. They don’t look like much, but they get the job done.

Wondering why they do it this way? It lets them mix materials, using titanium and alloy to save more weight, and keep manufacturing costs down…which helps make it more affordable for you, too.

Ok, let’s compare the cassettes:

DEORE CS-M6100

- All steel cogs

- Including a steel lock ring

- Painted spider

- 589g

SLX CS-M7100

- 11 smallest cogs are steel

- 1 largest is aluminum, and it’s anodized

- Keeps the painted spider

- 534g

- 55g savings over Deore

XT CS-M8100

- Bottom 10 cogs are steel

- 2 largest are anodized alloy

- Also keeps the painted spider

- 470g

- 64g savings over SLX

XTR CS-M9100

- 4 smallest are steel

- 5 middle cogs are Titanium

- 3 largest are aluminum

- Upgrades to anodized spider

- Upgrades to a special hard plating on aluminum cogs, which are then painted black. This improves overall alloy cog durability compared to the anodizing process used for SLX & XT.

- 367g

- 103g savings over XT

Shimano 12-Speed Shifter Comparison

The shifters have a few obvious differences on the outside, including how much adjustment range they have when used with iSpec brake lever clamps. But the biggest differences are internal and have to do with their feel and functionality.

All of them come in I-SPEC EV or Clamp Band mounting options. If you’re using the I-SPEC mounts, they all have a 14mm left-to-right slide adjustment range, so you can position the shifter farther inboard or outboard.

But I-Spec EV also allows for rotational adjustment in relation to the brake lever, and you’ll see some differences between the models. The rotation ranges mentioned below are actually based on the adjustment window on the brake lever, not the shifter. So, if you put a Deore shifter on an XTR brake lever, it would have 60º of rotational adjustment.

DEORE SL-M6100

- RapidFire Plus (which means you can downshift up to three easier gears at a time)

- Two-Way Release (which means you can push or pull to upshift to a harder gear)

- 10º of i-SPEC rotation angle adjust

- OptiSlick cables

- 132g (with band clamp, not I-Spec EV like others listed here)

SLX SL-M7100

- RapidFire Plus

- Two-Way Release

- 20º of i-SPEC rotation angle adjust

- Some covers and small parts made of glass fiber reinforced plastic

- The lever bodies are steel and glass fiber plastic, too, same for Deore

- Levers rotate on bushings inside the shell, same for Deore

- OptiSlick cables

- 117g

- (a few grams) lighter than Deore

XT SL-M8100

- RapidFire Plus, increased to four shifts

- Two-Way Release

- Adds Multi-Release, letting you upshift two gears at once if you want

- Also adds Instant release, meaning it shifts on the click, not the release

- 20º of i-SPEC rotation angle adjust

- Main lever upgrades to full aluminum construction with a grooved rubber grip pad

- Inside, it upgrades the lever and other movements to use two bearings

- 117g

- Same weight as SLX

XTR SL-M9100

- Same RapidFire Plus, Two-Way/Multi/Instant release features of XT

- 60º of i-SPEC rotation angle adjust

- Upgrades to a slicker Polymer-coated cable

- Inside, it upgrades to four bearings

- Covers and small parts upgraded to carbon fiber reinforced plastic

- Release lever upgraded to carbon fiber reinforced plastic

- 112g

- 5g lighter than XT

Shimano 12-Speed Rear Derailleur Comparison

All four 12-speed rear derailleurs use Shimano’s Shadow+ design, which basically means two things: First, that it’s a low profile design that doesn’t stick out from the chainstay so it’s less likely to get hit on a rock, tree, whatever.

Second, it’s the clutch, which helps the system stay quieter and keep your chain from bouncing so hard it comes off the chainring.

From there, it’s largely about materials differences and, again, the manufacturing technique and precision tolerances. And the shaping of the parallelograms and other body parts. Which is why you don’t see a ton of differences in the bullet point specs below, but you’ll see more physical differences when looking at them side by side (shown in video).

DEORE RD-M6100-SGS

- The pivot points on the parallelogram are moving on flouric coated bushings (same for all four derailleurs)

- Bushings inside pulley wheels

- Hollow stainless steel main bolt

- Steel pulley cage plates

- Glass Fiber Reinforced Plastic (GFRP) body parts

- 318g

SLX RD-M7100-SGS

- SLX and up add a bumper plate to pulley cage

- Keeps the bushings in the pulleys, but tighter tolerances

- Upgrades to anodized hollow stainless steel main bolt

- Painted Alloy pulley cage plates

- 316g

- 2g lighter than Deore

XT RD-M8100-SGS

- Upgrades to sealed bearings inside the pulleys, so they roll faster & easier

- Anodized hollow stainless steel main bolt

- Painted alloy pulley cage plates

- 285g

- 31g lighter than SLX

XTR RD-M9100-SGS

- Also uses sealed bearings inside the pulley wheels

- Carbon Fiber Reinforced Plastic (CFRP) body parts

- Where the other three have 7 fluoric coated link bushings, XTR gets 8

- Upgrades to alloy adjusting screw

- Upgrades to alloy main bolt

- Anodized alloy inner cage, CFRP outer plate

- Much more chiseled and shaped to remove weight

- 237g

- 48g lighter than XT

Other notes: XTR is the only 12-speed RD available in GS Medium Cage (for 10-45 cassettes). SLX, XT and XTR come in MX120 designs for use with 2×12 drivetrains, but Deore is 1×12 only.

Corrections from video: In the video I mistakenly say that Deore and up get the bumper plate on the pulley cage, but it’s only on SLX and higher. Also, Deore through XT use stainless B-axles (main mounting bolt), in the video I incorrectly say SLX and XT have alloy bolts.

A visual comparison between XT (top) and XTR (bottom) shows how Shimano removes more material from higher end derailleurs to save more weight. You can see more examples of this in the video.

Shimano 12-Speed MTB Group Actual Weights

(Weights & Pricing will be added as a chart here soon, so you’ll be able to find it all in one place. Follow us on social for an update when this is added. In the meantime, you can find all of that info throughout this story and in the posts linked below.)

For more information on each group, check out the launch coverage and first impressions at the following links:

- Shimano XTR M9100 – Launch Coverage / Actual Weights / Ride Review

- Shimano XT M8100 – Launch Coverage / Weights / Ride Review

- Shimano SLX M7100 – Launch Coverage / Weights

- Shimano Deore 6100 – Launch Coverage